DIY solder paste

Radio amateurs have long chosen such an innovation as solder paste. It was originally invented for soldering SMD components during machine assembly of boards. But now many people use this paste for ordinary manual soldering of parts, wires, metals, etc. It’s understandable - everything in one is at hand. After all, solder paste is almost actually a mixture of flux and solder.

In fact, to make solder paste for the needs of radio amateurs, it does not take much effort, time and ingredients.

To make solder paste we need:

I will make from these components. Ideally, it’s better to take:

The whole process is incredibly simple.

We start by grinding the solder. I took a thick tubular piece and began to chop it up with a file, a needle file and a mechanical drill attachment. What you use is up to you. But I am for mechanics, since manual labor is too long and painstaking.

The smaller the crumb, the better.Small quantity required.

Then add Vaseline in a 1:1 ratio and a little LTI flux (these two ingredients can be replaced with solder fat).

Mix everything thoroughly.

For better stirring, the mixture can be heated in a water bath or with a regular soldering iron, reducing its heat to 90 degrees Celsius.

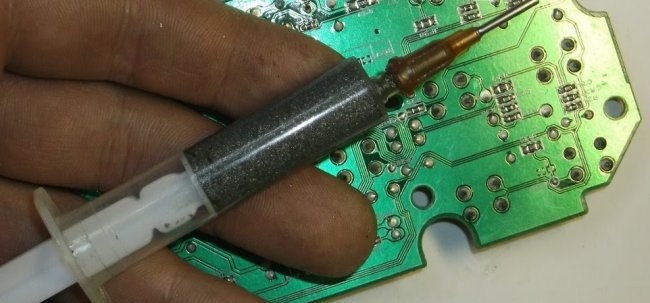

Next, for storage, transfer the resulting paste into a syringe with a thick specialized needle. Or no needle at all.

At this point the paste is ready for use.

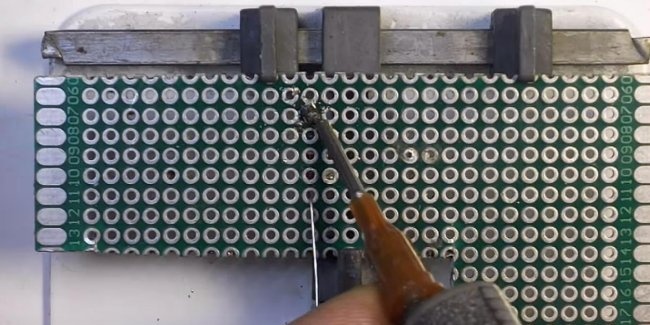

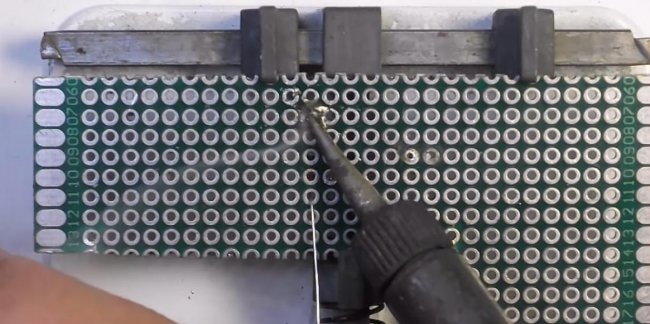

Apply a little paste to the soldering area and solder with a soldering iron.

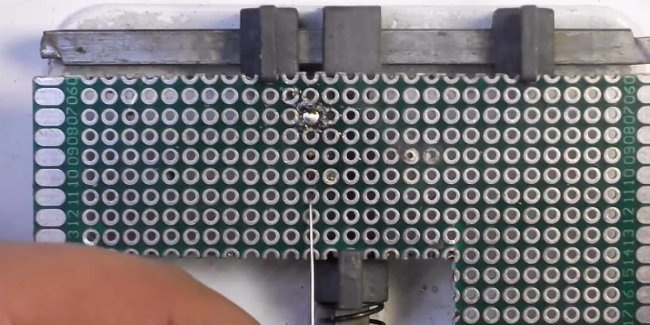

Everything is soldered very neatly and practically without streaks.

What kind of fluxes and solders do you make? Write in the comments, I will be very interested. Thank you!

In fact, to make solder paste for the needs of radio amateurs, it does not take much effort, time and ingredients.

To make solder paste we need:

- Tin-lead solder rod;

- Medical Vaseline. Used as a thickener;

- Flux LTI-120 or other liquid.

I will make from these components. Ideally, it’s better to take:

- Tin-lead solder rod;

- Soldering fat. And if you find “active fat,” it’s absolutely beautiful.

How to make solder paste?

The whole process is incredibly simple.

We start by grinding the solder. I took a thick tubular piece and began to chop it up with a file, a needle file and a mechanical drill attachment. What you use is up to you. But I am for mechanics, since manual labor is too long and painstaking.

The smaller the crumb, the better.Small quantity required.

Then add Vaseline in a 1:1 ratio and a little LTI flux (these two ingredients can be replaced with solder fat).

Mix everything thoroughly.

For better stirring, the mixture can be heated in a water bath or with a regular soldering iron, reducing its heat to 90 degrees Celsius.

Next, for storage, transfer the resulting paste into a syringe with a thick specialized needle. Or no needle at all.

At this point the paste is ready for use.

Soldering paste test

Apply a little paste to the soldering area and solder with a soldering iron.

Everything is soldered very neatly and practically without streaks.

What kind of fluxes and solders do you make? Write in the comments, I will be very interested. Thank you!

Watch a video on making solder paste

Similar master classes

Particularly interesting

Cable antenna for digital TV in 5 minutes

A selection of simple and effective schemes.

Three-phase voltage from single-phase in 5 minutes

Starting a three-phase motor from a single-phase network without a capacitor

Eternal flashlight without batteries

How to make an inexpensive but very powerful LED lamp

Comments (3)