We extract gold from radio components

Experiments on extracting precious metals from circuit boards, microcircuits, transistors and other radio components are no longer new, and they are hotly discussed on the Internet. Many people discovered talented chemists in themselves in this way, and some make good money. Interest in this topic is fueled by the desire to obtain valuable metal from worthless elements, many of which end up in workshop storerooms, office sumps, and even lie in trash bins. Moreover, this can be done not in specialized laboratories, but in ordinary home conditions. How is this possible? Let's get a look.

Surely many who heard about these experiments wondered: why the contacts are covered or even made of such a precious metal as gold. After all, silver is much cheaper, and in terms of electrical conductivity it even surpasses the yellow metal. It's actually not that complicated. Silver tends to oxidize over time, and this is detrimental to contact groups. Gold does not react with any element of the periodic table, and remains unchanged for a long time. Therefore, time is powerless over contact groups that are coated with gold!

To speed up the reaction you will need an electric stove.

The method we will be looking at today is based on chemically etching or reducing gold and separating it from other metals. To conduct such chemical experiments, it is necessary to provide ventilation, use protective clothing, goggles, a respirator and gloves.

For chemical experiments, we use a liter vessel and pour 100 ml of water into it. We place the entire set of processed radio components in it.

Pour in 1.5-2 tablespoons of table or rock salt (halite) and stir the resulting mixture.

Next, add 100 ml of nitric acid into a 150 ml glass container. You must work with this reagent very carefully, protecting yourself with thick rubber gloves.

Pour nitric acid into a liter vessel with radio components. The etching reaction with the release of oxide vapors occurs immediately and almost completely dissolves all metals, with the exception of gold, converting some into oxides, others into nitrates.

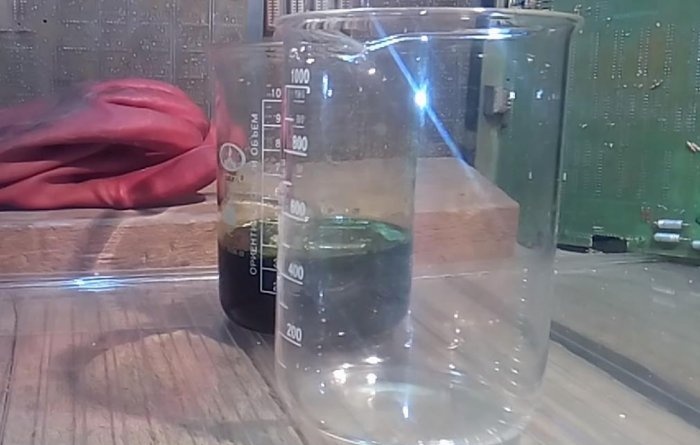

The result will be a saturated, dark green solution. If necessary, complete the etching reaction, you can add another 100 ml of nitric acid.

We make a funnel with a filter from a plastic watering can and cotton wool. We insert the cotton wool into the drain hole and pour the solution into it along with all the contents. Place the watering can in a clean liter container.

The remaining radio components can be removed.We heat the filtered solution on the stove and begin to quench the nitric acid. We will do this using urea - a simple and cheap ingredient that can be bought at any flower shop that sells fertilizers.

Add urea one tablespoon at a time, constantly stirring the solution in the container. In this case, nitrogen vapor should be released. The addition of urea powder must be done until the quenching reaction stops.

Next, we heat the container with the solution to 80-85 degrees Celsius, since in a cold solution the process of quenching nitric acid with urea will not be completed completely.

The final stage of our chemical experiment will be the isolation of the resulting metal from a solution of quenched nitric acid. To do this, add a few tablespoons of iron sulfate (ferrous sulfate) to 100 ml of water and stir thoroughly. The resulting reagent is poured in small portions into a liter container with metal sediments.

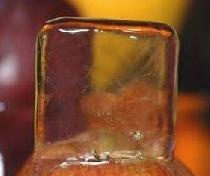

Place the container with the solution on the electric stove and heat for ten minutes, stirring alternately. After pouring the acid solution into another container, small coagulated gold particles should remain at the very bottom.

All that remains to be done is to melt them in a crucible into a single ingot of precious metal.

Why gold

Surely many who heard about these experiments wondered: why the contacts are covered or even made of such a precious metal as gold. After all, silver is much cheaper, and in terms of electrical conductivity it even surpasses the yellow metal. It's actually not that complicated. Silver tends to oxidize over time, and this is detrimental to contact groups. Gold does not react with any element of the periodic table, and remains unchanged for a long time. Therefore, time is powerless over contact groups that are coated with gold!

Process video

Required ingredients and reagents

- Glass measuring cups made of laboratory glass – 150 ml (1 piece), 1000 ml (2 pieces);

- Radio components - transistors, microcircuits, contact connectors, sockets, switches, etc.;

- Water;

- Rock or table salt;

- Nitric acid;

- Urea;

- Inkstone.

To speed up the reaction you will need an electric stove.

Let's get started with the chemical process of producing gold

The method we will be looking at today is based on chemically etching or reducing gold and separating it from other metals. To conduct such chemical experiments, it is necessary to provide ventilation, use protective clothing, goggles, a respirator and gloves.

For chemical experiments, we use a liter vessel and pour 100 ml of water into it. We place the entire set of processed radio components in it.

Pour in 1.5-2 tablespoons of table or rock salt (halite) and stir the resulting mixture.

Next, add 100 ml of nitric acid into a 150 ml glass container. You must work with this reagent very carefully, protecting yourself with thick rubber gloves.

Pour nitric acid into a liter vessel with radio components. The etching reaction with the release of oxide vapors occurs immediately and almost completely dissolves all metals, with the exception of gold, converting some into oxides, others into nitrates.

The result will be a saturated, dark green solution. If necessary, complete the etching reaction, you can add another 100 ml of nitric acid.

We make a funnel with a filter from a plastic watering can and cotton wool. We insert the cotton wool into the drain hole and pour the solution into it along with all the contents. Place the watering can in a clean liter container.

The remaining radio components can be removed.We heat the filtered solution on the stove and begin to quench the nitric acid. We will do this using urea - a simple and cheap ingredient that can be bought at any flower shop that sells fertilizers.

Add urea one tablespoon at a time, constantly stirring the solution in the container. In this case, nitrogen vapor should be released. The addition of urea powder must be done until the quenching reaction stops.

Next, we heat the container with the solution to 80-85 degrees Celsius, since in a cold solution the process of quenching nitric acid with urea will not be completed completely.

The final stage of our chemical experiment will be the isolation of the resulting metal from a solution of quenched nitric acid. To do this, add a few tablespoons of iron sulfate (ferrous sulfate) to 100 ml of water and stir thoroughly. The resulting reagent is poured in small portions into a liter container with metal sediments.

Place the container with the solution on the electric stove and heat for ten minutes, stirring alternately. After pouring the acid solution into another container, small coagulated gold particles should remain at the very bottom.

All that remains to be done is to melt them in a crucible into a single ingot of precious metal.

Similar master classes

Particularly interesting

Comments (6)