Making a powerful blower with your own hands

Many things that seem unnecessary to us can actually be used in the household. You just have to set yourself the goal of realizing an incredible idea, and the solution may come on its own. And the resulting creation will forever be remembered for the exciting moments of creativity in the home workshop.

And how can we not remember about cleaning, because this event sometimes cancels out all creative impulses. Putting order and cleanliness around you and the world around you is very important, but not always pleasant. But there is a way out, and we will show it to you today.

Remove leaves from paths, garbage from the site or other unnecessary things - you can do anything with it! And most importantly, with such a device, any cleaning will turn into a pleasant, and certainly not boring, pastime.

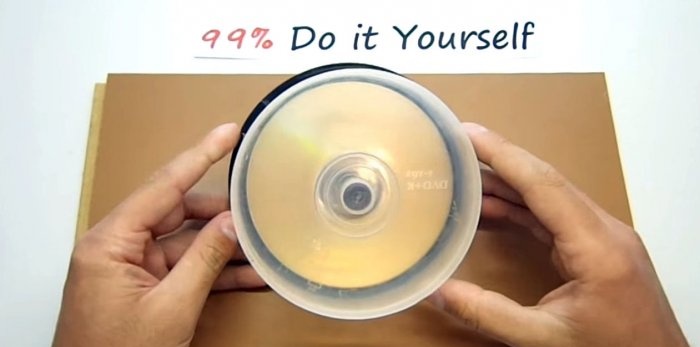

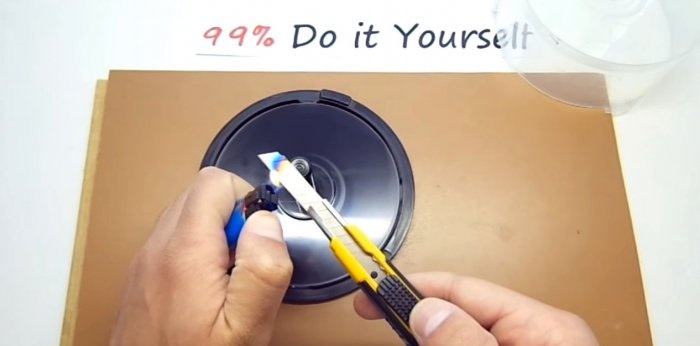

First, prepare an empty disc box. It needs to dismantle the cylindrical axis. We cut it with a heated blade of a painting knife and break it by hand.

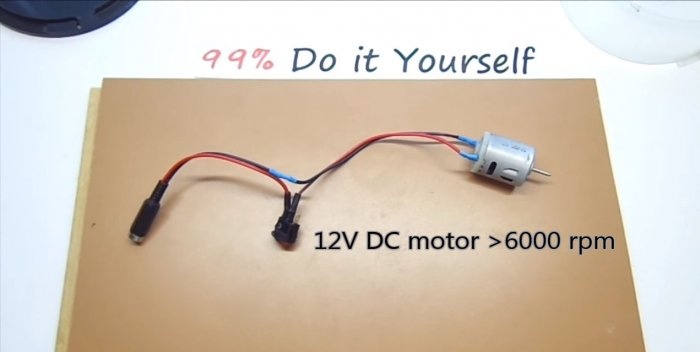

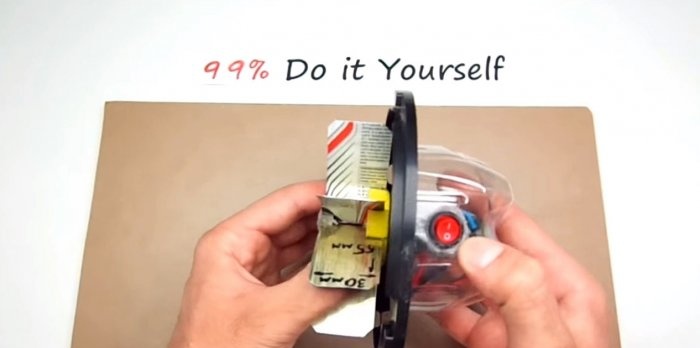

We take a 12 V DC motor and connect to it a switch button with a connector for the power supply as shown in the photo.

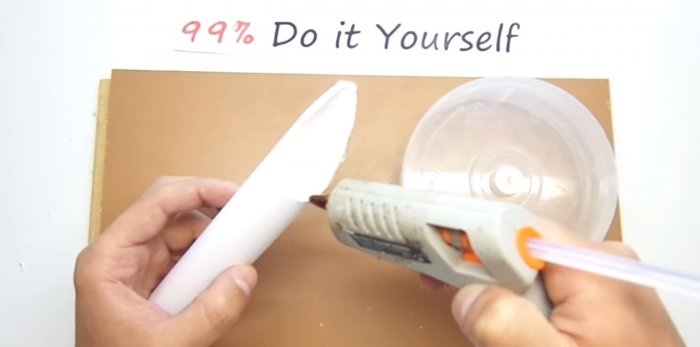

We attach the engine to the back of the disc platform using hot glue. We carefully glue the body around the entire circumference.

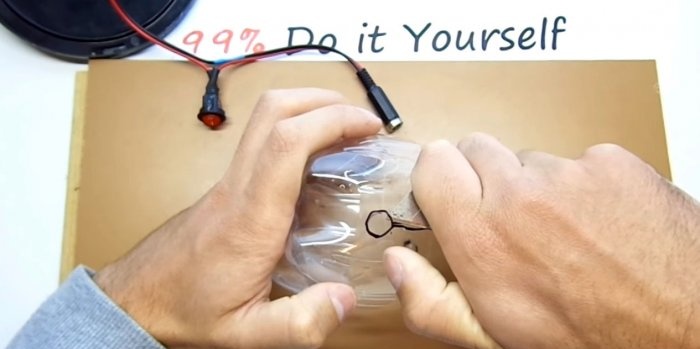

The next step will be cutting a liter plastic bottle (PET). We measure 6 cm from the bottom of the bottle, and cut off a small cap with a paint knife. We won't need the rest of the bottle.

Next, we make several holes from the bottom in this cap. They are needed for the switch and charging socket. Using hot glue we attach a switch button and a connector for the power supply to the inside of the cap.

Apply hot glue to the outer edge of the cap and glue it to the back of the disk platform.

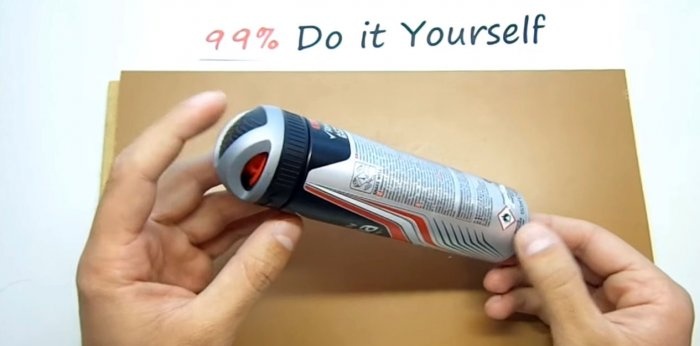

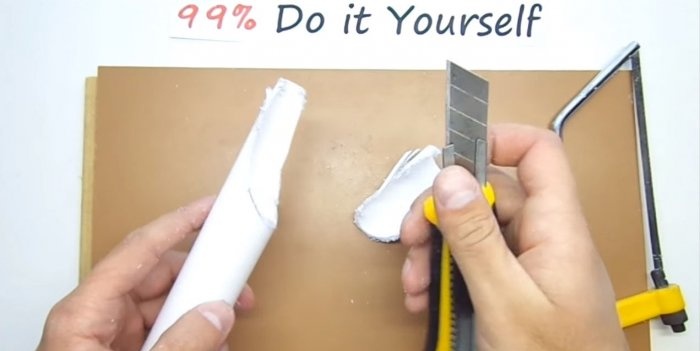

We will prepare impeller blades from an empty metal deodorant bottle. Using a hacksaw, we cut off the bottom and neck of the bottle, and cut the body lengthwise with ordinary scissors.

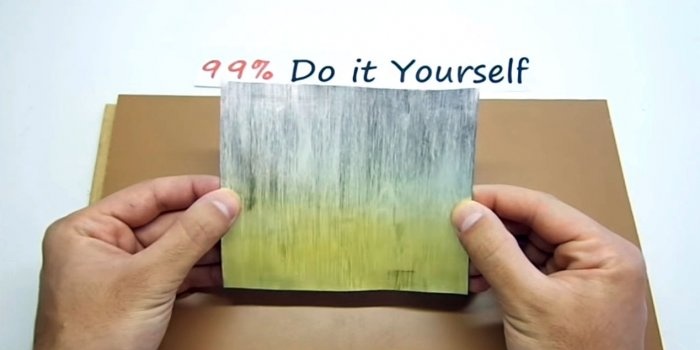

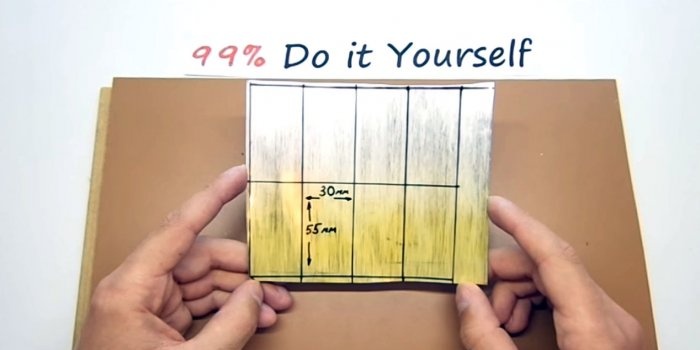

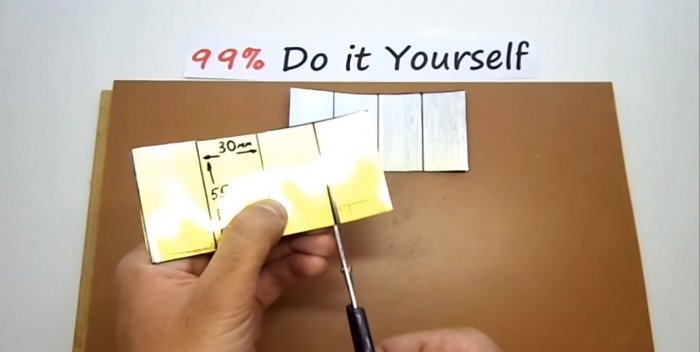

We level the resulting piece of tin manually and begin marking. Using a marker and a ruler, draw the sheet into eight rectangles with dimensions of 30x55 mm. We cut them out with scissors, biting off the corners on one side of each blade.

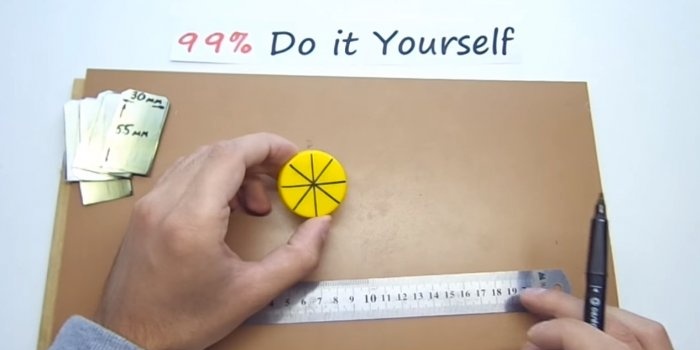

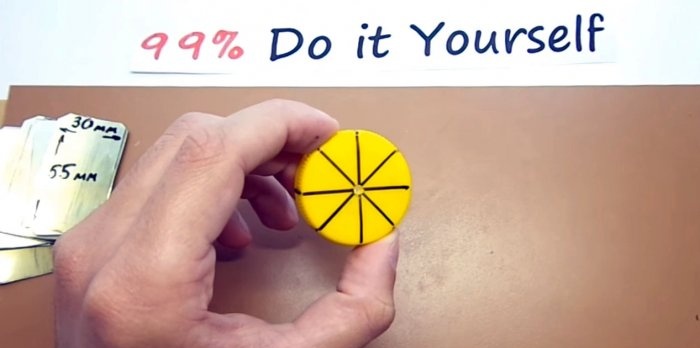

We use a plastic bottle cap as a hub. We divide it into eight identical parts with four diagonals. We lower the extreme marking points onto the ribs.

We make a small hole in the center of the hub cover for the motor shaft.We cut the ribs according to the markings with a hacksaw or knife.

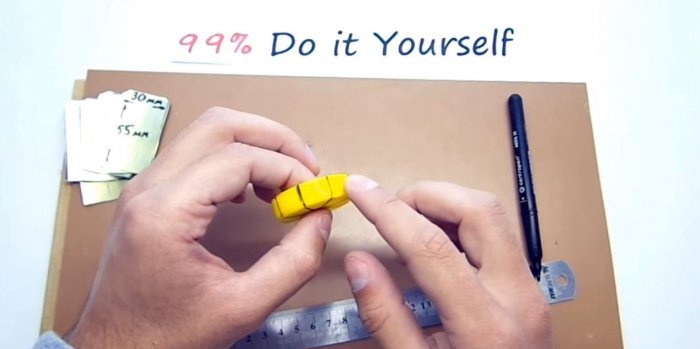

We assemble the impeller by inserting the blades into the slots in the cover and attaching them to hot glue. We additionally glue the center of the impeller, and then give the blades a slight tilt by bending them manually. This is necessary to provide greater air flow output.

We make the outlet air duct from a 25 mm piece of plastic pipe. The circumference of the disc box cover will serve as a template for the air duct.

We mark it with a marker and cut it with a hacksaw. We trim the joint with a paint knife.

We mark the mounting hole for the air duct on the body of the plastic cover. Using a paint knife, make a slot in the lid for the pipe. We securely seal the air duct connection with hot glue.

We cut the air intake hole in the center of the plastic disk cover.

We fix the impeller with the hub on the motor shaft with hot glue, and cover it with a plastic cover with an air duct, wedging the shutter of the disc box.

We connect the blower to a 12 V power supply and check its functionality. Everything works properly, and now you can safely start cleaning!

And how can we not remember about cleaning, because this event sometimes cancels out all creative impulses. Putting order and cleanliness around you and the world around you is very important, but not always pleasant. But there is a way out, and we will show it to you today.

Remove leaves from paths, garbage from the site or other unnecessary things - you can do anything with it! And most importantly, with such a device, any cleaning will turn into a pleasant, and certainly not boring, pastime.

Materials-tools

- CD/DVD box;

- 12V DC motor, 6000rpm;

- Switch button;

- 5.5 mm connector for power supply;

- Empty metal deodorant bottle;

- Liter plastic bottle (PET);

- Plastic bottle cap;

- A 25 mm piece of PVC pipe;

- Hot glue gun, soldering iron;

- Paint knife, scissors, marker, ruler and small hacksaw.

Let's start making the blower

First, prepare an empty disc box. It needs to dismantle the cylindrical axis. We cut it with a heated blade of a painting knife and break it by hand.

We take a 12 V DC motor and connect to it a switch button with a connector for the power supply as shown in the photo.

We attach the engine to the back of the disc platform using hot glue. We carefully glue the body around the entire circumference.

The next step will be cutting a liter plastic bottle (PET). We measure 6 cm from the bottom of the bottle, and cut off a small cap with a paint knife. We won't need the rest of the bottle.

Next, we make several holes from the bottom in this cap. They are needed for the switch and charging socket. Using hot glue we attach a switch button and a connector for the power supply to the inside of the cap.

Apply hot glue to the outer edge of the cap and glue it to the back of the disk platform.

We will prepare impeller blades from an empty metal deodorant bottle. Using a hacksaw, we cut off the bottom and neck of the bottle, and cut the body lengthwise with ordinary scissors.

We level the resulting piece of tin manually and begin marking. Using a marker and a ruler, draw the sheet into eight rectangles with dimensions of 30x55 mm. We cut them out with scissors, biting off the corners on one side of each blade.

We use a plastic bottle cap as a hub. We divide it into eight identical parts with four diagonals. We lower the extreme marking points onto the ribs.

We make a small hole in the center of the hub cover for the motor shaft.We cut the ribs according to the markings with a hacksaw or knife.

We assemble the impeller by inserting the blades into the slots in the cover and attaching them to hot glue. We additionally glue the center of the impeller, and then give the blades a slight tilt by bending them manually. This is necessary to provide greater air flow output.

We make the outlet air duct from a 25 mm piece of plastic pipe. The circumference of the disc box cover will serve as a template for the air duct.

We mark it with a marker and cut it with a hacksaw. We trim the joint with a paint knife.

We mark the mounting hole for the air duct on the body of the plastic cover. Using a paint knife, make a slot in the lid for the pipe. We securely seal the air duct connection with hot glue.

We cut the air intake hole in the center of the plastic disk cover.

We fix the impeller with the hub on the motor shaft with hot glue, and cover it with a plastic cover with an air duct, wedging the shutter of the disc box.

We connect the blower to a 12 V power supply and check its functionality. Everything works properly, and now you can safely start cleaning!

Watch the video

Similar master classes

Particularly interesting

Comments (0)