How to make a powerful turbo blower

Only a constant fight against dust allows us to keep our homes in relative order. But there are places in the house where a lot of dust accumulates, and it is impossible, or even prohibited, to remove it with a rag or brush. We are talking about air conditioners, computer system units, uninterruptible power supplies (UPS), household transformers, etc. In this case, a compact, powerful turbo blower will help us, which is not so difficult to make with your own hands.

From the materials we need to prepare:

To work on the blower you will have to use: a soldering iron, a ruler, a compass and a marker, scissors, a screwdriver and pliers, and a glue gun.

We mark a round tin blank, using a ruler, compass and marker, under the side of the blower body in the form of a “snail” and cut it out with scissors.

Using the cut out sidewall as a template, we trace its outline on another piece of tin and also cut along the outline with scissors.

We use one of the sidewalls to install a 24 V DC motor. To do this, mark a hole in the center for the axle and two holes next to it to secure it. In the other sidewall in the center we make a large round hole for air intake.

We mark and cut out a tin disk with a central hole with two nuts soldered to it on one side.

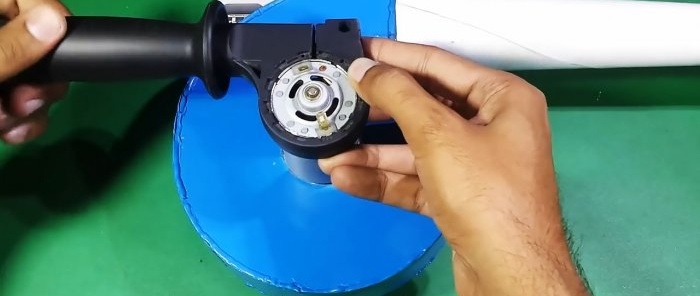

We secure the engine with two screws with large heads to the side frame, which was already prepared for this in advance. We try on a tin plate with nuts soldered to the smooth motor shaft.

We divide the tin disk into six equal parts in the radial direction and make the appropriate markings. Along it we solder vertically six identical rectangular plates at the same distance from the center of rotation. Moreover, the gaps between the outer and side edges of the plates and the blower body should be minimal.

We place the impeller on the smooth motor shaft and secure it with glue.

We bend a tin strip of adjusted width along the contour of the side of the case and solder it in several places.

We place the second side panel on the cylindrical part of the body and also secure it with a soldering iron and solder.

We install and solder a cylindrical tin pipe onto the suction hole.

Using a glue gun, seal all joints on the blower body. After the glue has dried, paint the body of the blower with aerosol paint from a can.

We roll up a partial cone from thick glossy paper and place the larger side on the outlet pipe of the blower body and secure it with glue from a gun.

We install and secure the handle of the drilling machine on the cylindrical surface of the engine.

We solder the wires to the motor contacts, connecting the on/off button into the circuit, which we attach to the handle in a convenient place.

By turning on the start button, we supply 24 VDC to the blower motor from the appropriate power supply (battery).

We are testing our homemade product on the outdoor part of the air conditioner.

We blow it in the direction opposite to the accepted one. We notice that clouds of dust and even small pebbles, leaves and other foreign bodies are coming out of it.

Remove the cover and side panel of the UPS. We direct the air stream from the blower into the device. It’s amazing how so much dust, cobwebs and dirt can fit into such a small space!

Will need

From the materials we need to prepare:

- thin galvanized sheet;

- DC motor 24 V (or 12 V) - http://ali.pub/3srgsi;

- on/off button;

- two nuts and two large head screws;

- soldering wire with flux;

- a can of aerosol paint;

- thick glossy paper and glue;

- drill press handle;

- power supply with wires.

To work on the blower you will have to use: a soldering iron, a ruler, a compass and a marker, scissors, a screwdriver and pliers, and a glue gun.

Blower manufacturing process

We mark a round tin blank, using a ruler, compass and marker, under the side of the blower body in the form of a “snail” and cut it out with scissors.

Using the cut out sidewall as a template, we trace its outline on another piece of tin and also cut along the outline with scissors.

We use one of the sidewalls to install a 24 V DC motor. To do this, mark a hole in the center for the axle and two holes next to it to secure it. In the other sidewall in the center we make a large round hole for air intake.

We mark and cut out a tin disk with a central hole with two nuts soldered to it on one side.

We secure the engine with two screws with large heads to the side frame, which was already prepared for this in advance. We try on a tin plate with nuts soldered to the smooth motor shaft.

We divide the tin disk into six equal parts in the radial direction and make the appropriate markings. Along it we solder vertically six identical rectangular plates at the same distance from the center of rotation. Moreover, the gaps between the outer and side edges of the plates and the blower body should be minimal.

We place the impeller on the smooth motor shaft and secure it with glue.

We bend a tin strip of adjusted width along the contour of the side of the case and solder it in several places.

We place the second side panel on the cylindrical part of the body and also secure it with a soldering iron and solder.

We install and solder a cylindrical tin pipe onto the suction hole.

Using a glue gun, seal all joints on the blower body. After the glue has dried, paint the body of the blower with aerosol paint from a can.

We roll up a partial cone from thick glossy paper and place the larger side on the outlet pipe of the blower body and secure it with glue from a gun.

We install and secure the handle of the drilling machine on the cylindrical surface of the engine.

We solder the wires to the motor contacts, connecting the on/off button into the circuit, which we attach to the handle in a convenient place.

Blower testing

By turning on the start button, we supply 24 VDC to the blower motor from the appropriate power supply (battery).

We are testing our homemade product on the outdoor part of the air conditioner.

We blow it in the direction opposite to the accepted one. We notice that clouds of dust and even small pebbles, leaves and other foreign bodies are coming out of it.

Remove the cover and side panel of the UPS. We direct the air stream from the blower into the device. It’s amazing how so much dust, cobwebs and dirt can fit into such a small space!

Watch the video

Similar master classes

Particularly interesting

Comments (2)