Laser level from scrap materials

The use of a level or level in repair work is extremely important. With the help of such a device, you can easily and absolutely accurately carry out installation and assembly work. And the more accurate the device is, the less error there will be in the measurements. Laser measuring equipment is considered the most accurate today.

Laser levels or levels won’t surprise anyone today. They have become so popular that varieties of them can be bought in almost every hardware store. Only their price still leaves much to be desired. And for an ordinary person who is not involved in repairs or construction every day, buying a laser level is unlikely to be a rational decision. What to do in a situation where the tool is not cheap, but is only needed for a one-time use? The answer is simple - do it yourself. You heard right, it’s really real, and for a ridiculous price.

The tools we will need are:

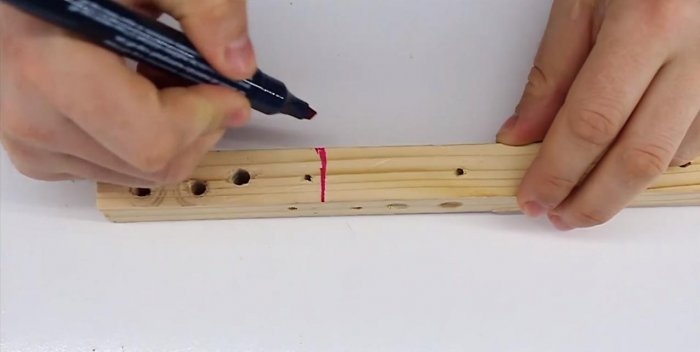

We cut a small piece 8-10 cm long from a wooden block. This will be the basis of our laser level.

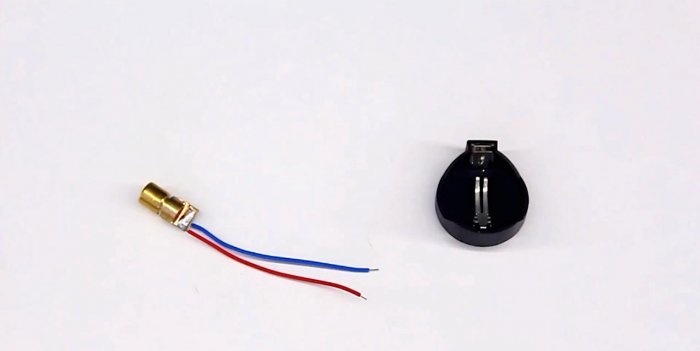

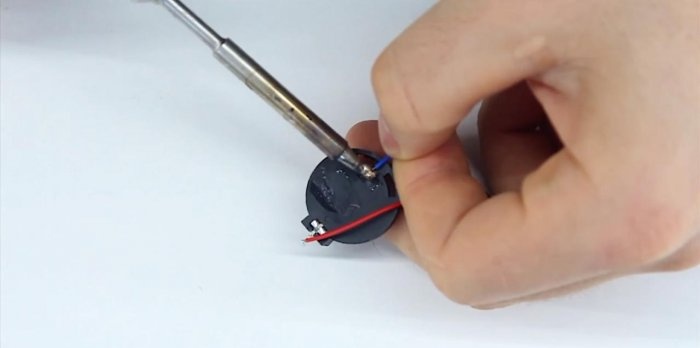

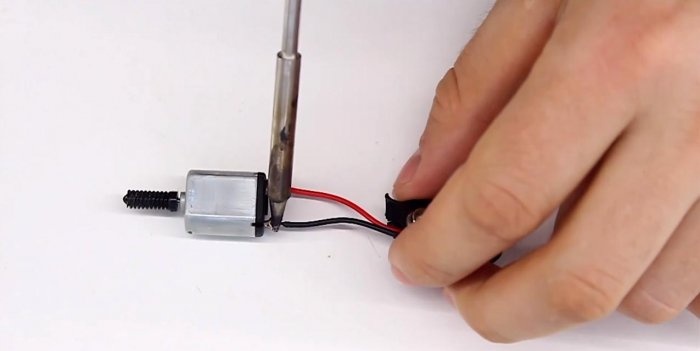

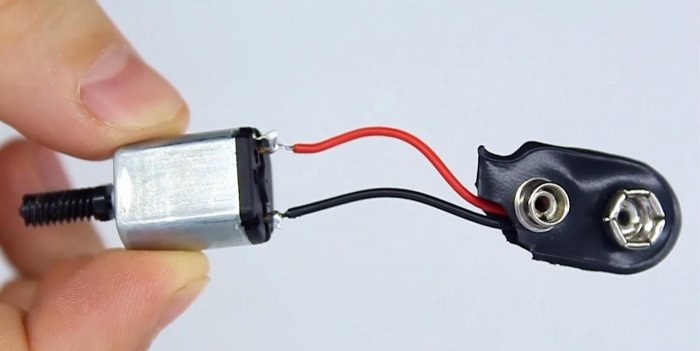

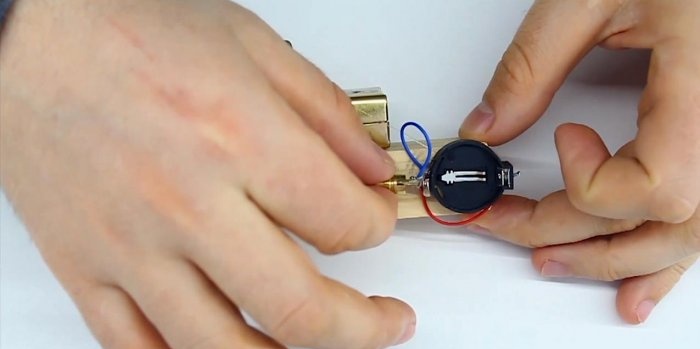

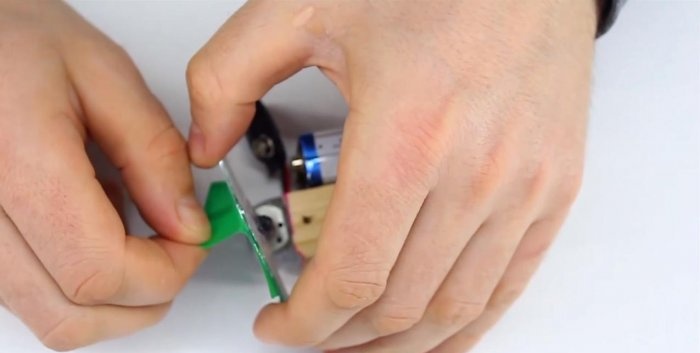

Then we connect the plastic holder with terminals and the laser module with several wires, observing the polarity. We do the same with the connector for the “crown” and the engine.

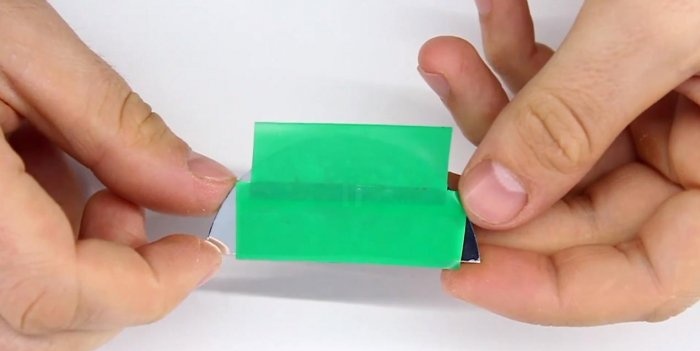

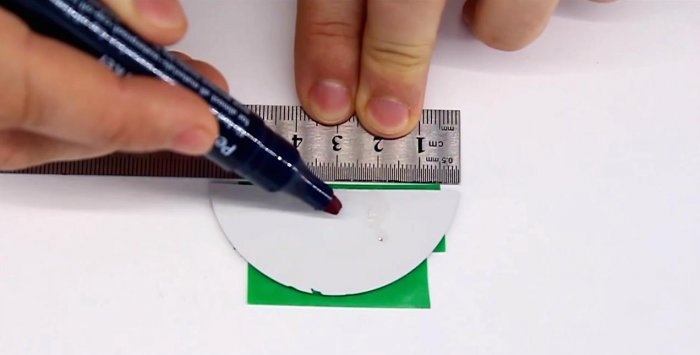

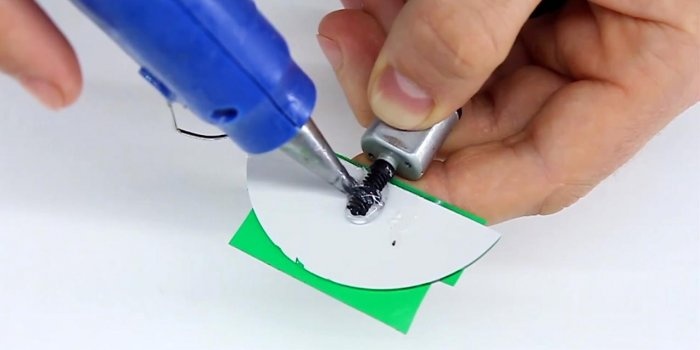

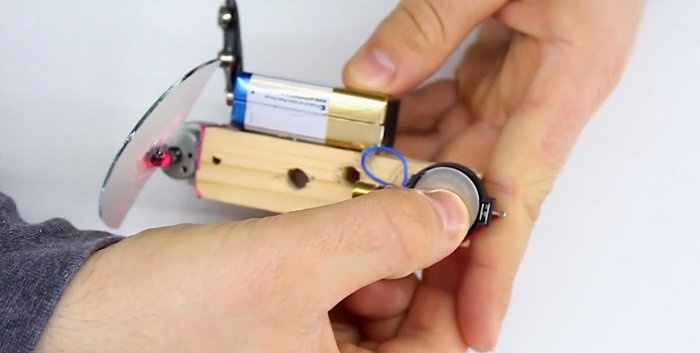

We seal the mirror with electrical tape so as not to damage the glass surface. We mark the middle of it on the back side with a ruler, and glue the engine shaft along the mark with hot glue.

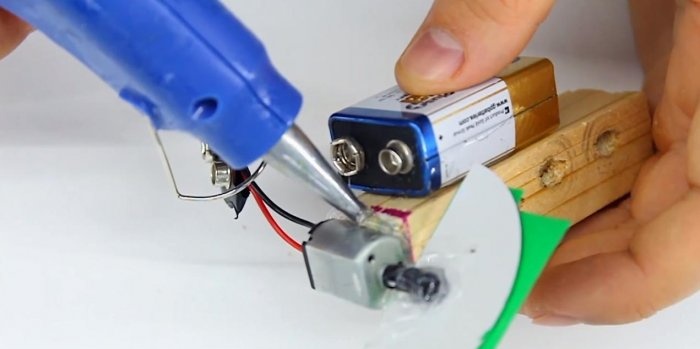

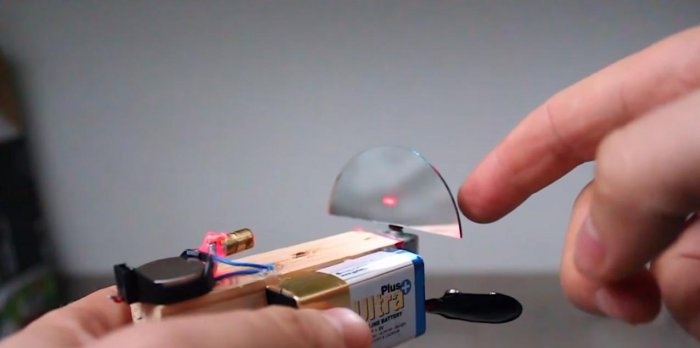

Using a hot glue gun we glue a “crown” onto the end of a wooden block, and at the end there is a slider with a mirror. The motor shaft must be outside the block so that the mirror can move freely around the shaft axis.

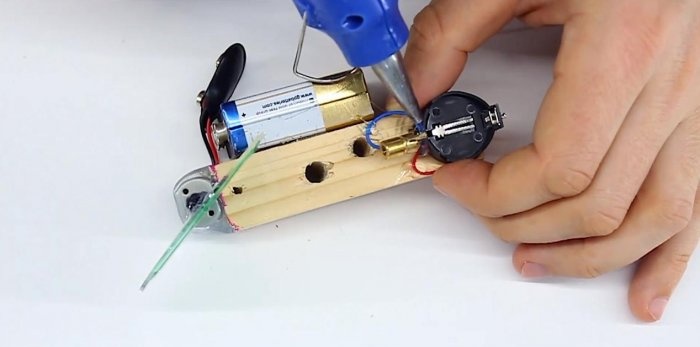

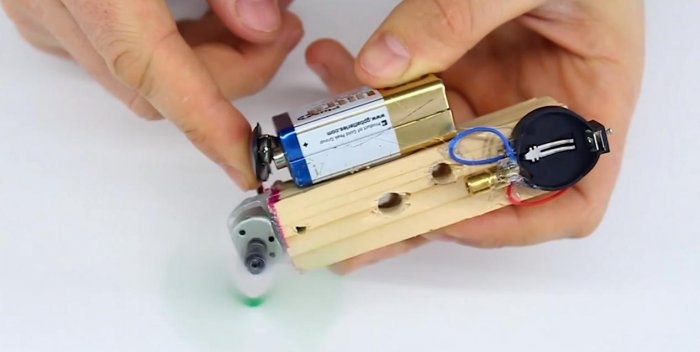

We glue the laser module with the plastic battery holder last. The smoother this laser element is glued, the more accurate the line it marks on the measured surface will be.

Remove the electrical tape from the mirror and insert the CR 2032 batteries into the battery container.

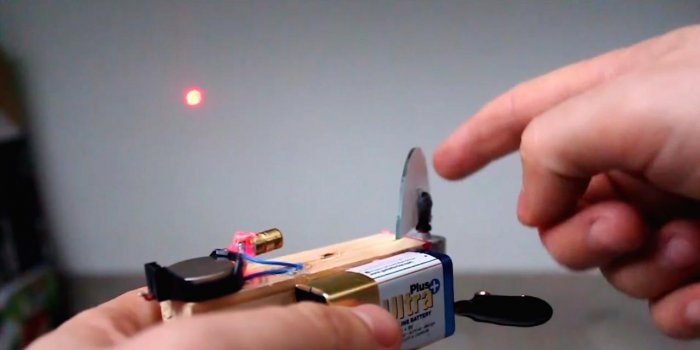

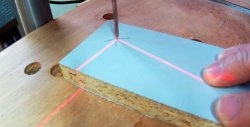

The device is ready, all that remains is to connect the power and direct it to the nearest wall or ceiling. If such a device is mounted on a bubble level and its position is adjusted relative to the base surface, it can be used to obtain a clearly visible mark.

But if you turn on the engine, then due to the rotating mirror it will turn into an even solid line.

And on it you can easily display linear, planar or volumetric objects, such as ceramic tiles, drywall, polyurethane moldings, laminate and even furniture!

Laser levels or levels won’t surprise anyone today. They have become so popular that varieties of them can be bought in almost every hardware store. Only their price still leaves much to be desired. And for an ordinary person who is not involved in repairs or construction every day, buying a laser level is unlikely to be a rational decision. What to do in a situation where the tool is not cheap, but is only needed for a one-time use? The answer is simple - do it yourself. You heard right, it’s really real, and for a ridiculous price.

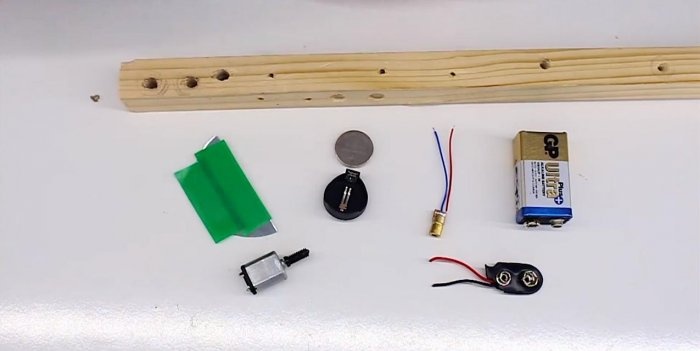

What you need for a homemade laser level

- Wooden block 80x20x30 mm;

- 9 V Krona battery with a connector for its contact connector;

- Battery CR 2032 – 2 pcs with plastic holder with terminals;

- Laser module 3 ~ 5 V, laser color – red;

- Small 5-12V DC motor;

- Half of a round ladies' mirror.

The tools we will need are:

- Soldering iron with solder;

- Hot glue gun with rods;

- Copper wiring;

- Hacksaw for metal;

- Insulating tape;

- Ruler, marker.

We make a laser level with our own hands

We cut a small piece 8-10 cm long from a wooden block. This will be the basis of our laser level.

Then we connect the plastic holder with terminals and the laser module with several wires, observing the polarity. We do the same with the connector for the “crown” and the engine.

We seal the mirror with electrical tape so as not to damage the glass surface. We mark the middle of it on the back side with a ruler, and glue the engine shaft along the mark with hot glue.

Using a hot glue gun we glue a “crown” onto the end of a wooden block, and at the end there is a slider with a mirror. The motor shaft must be outside the block so that the mirror can move freely around the shaft axis.

We glue the laser module with the plastic battery holder last. The smoother this laser element is glued, the more accurate the line it marks on the measured surface will be.

Remove the electrical tape from the mirror and insert the CR 2032 batteries into the battery container.

The device is ready, all that remains is to connect the power and direct it to the nearest wall or ceiling. If such a device is mounted on a bubble level and its position is adjusted relative to the base surface, it can be used to obtain a clearly visible mark.

But if you turn on the engine, then due to the rotating mirror it will turn into an even solid line.

And on it you can easily display linear, planar or volumetric objects, such as ceramic tiles, drywall, polyurethane moldings, laminate and even furniture!

Watch the video

Similar master classes

Particularly interesting

Comments (0)