Hanging loop made from scrap materials

I urgently needed a hinge for an iron door made of a square pipe to a utility room. I couldn’t find it in the workshop, and I didn’t want to go to the market at all, and then I figured out how to easily and quickly get out of the situation. In addition, the time spent replacing an ordinary loop with a homemade knot is so small (literally 2-3 minutes) that every DIY enthusiast should definitely know this method.

What do we need

Materials:

- Threaded rod (with a large pitch) with a diameter of 12 mm and a length of 5-7 cm;

- 4 threaded nuts for stud.

Tools:

- Welding machine.

Preparing an improvised loop

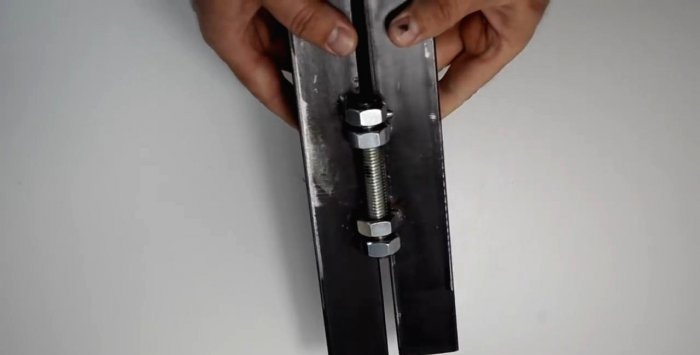

At the edges of the stud, tighten two nuts per side. We position them so that the outer ones are no further than 5 mm from the end of the pin. In this case, the inner nuts should not come into contact with the outer ones - the same distance should be left between them.

When operating a homemade hinge, the load on the axle will be minimal, so there is no need to worry that sooner or later it will fail - the connections will remain operational until they completely rust.

Weld the loop

We expose the iron structure (for ease of work, it is better to give it a horizontal position). We apply a homemade hinge so that its axis is between the edges of the pipes of the future door and its frame and is parallel to them. We perform welding work as follows: we connect the lower nuts at both ends of the hinge to the frame, and the upper nuts to the moving door. This will ensure maximum reliability and resistance to stress.

As soon as you make a slight inaccuracy and weld the hinge at a slight angle in relation to the frame and door leaf, the whole undertaking becomes a pointless waste of effort and waste of materials. Such a hinge will not last even a day - it will be enough to open the door just a few times, and the distortion will make itself known by tearing off the welded nuts. Therefore, when performing work, you should maintain high marking accuracy and it is better to use a backing for the pin so that the correctly aligned hinge does not move during welding.

Safety precautions

Working with a welding machine requires the presence of personal protective equipment, and a welding mask is not its only attribute. There should be mittens on the hands (gloves), and the welder himself should wear a work jacket.

The result is an excellent connection that will last as long as the original hinge.

Watch the video

Similar master classes

Particularly interesting

Comments (8)