Carbon filter for plastic bottle

While fishing, hiking or outdoor recreation, it may happen that drinking water becomes unusable. Either it’s over or it’s spilled – it doesn’t matter. In general, you can get water from the nearest reservoir, boil it, wait until it cools down and drink in peace. But in my opinion, this is a long time. It is much faster and more efficient to use a pre-prepared, homemade carbon filter. This filter is essentially a hiking accessory, and after its manufacture and successful use, it always lies in a hiking backpack, just in case. Moreover, it takes up almost no space. And it won’t take much time to make it.

Will need

- Plastic tube (or something similar).

- Cap from a plastic bottle.

- Activated carbon 1.5 packs.

- Birch coal.

- Synthetic tape, 10 mm wide.

- Felt, 5 mm thick.

- Scissors.

- Ruler.

- Compass.

- 3 mm drill.

- Burner or soldering iron.

Manufacturing of carbon filter

First you need to grind the coal. First activated, then birch. In different dishes.Under no circumstances should you grind it into fine dust, otherwise you will end up with a long plug instead of a filter! The pieces should be 1.5 - 2 mm. You can sift the crushed coal through an appropriate sieve.

After the coal is ready, let's start with the wads. Using a ruler, measure the inner diameter of the tube and draw the corresponding circles on the felt with a compass. Cut out these circles.

These will be wads between the layers so that later the coal does not mix inside the tube. You will need four of them. Now we wipe the tube with medical alcohol, thus disinfecting it, as well as removing the remnants of the contents previously stored in it. We wait until the alcohol dries inside. Place one wad on the bottom of the tube.

Add crushed activated carbon. Place the second wad on top of the coal.

Under no circumstances should we compact the layers, otherwise the water will filter out very slowly. Just as they poured it, let it lie there. Now we take the synthetic tape and wind it into a roll the size of the inner diameter of the tube.

We lower this roll flat into the tube. We place the third wad on top of it.

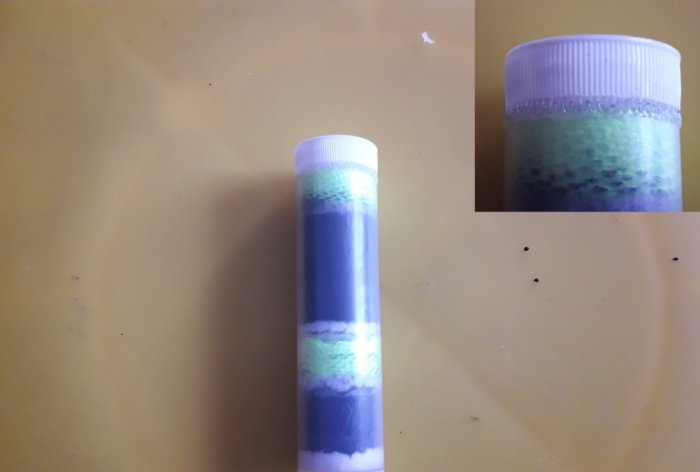

We fill in crushed birch charcoal so that there is a space left to the edge as wide as the thickness of the last wad and another roll of tape.

Next, place the fourth wad and the last roll of tape on top. This created a full tube.

Now we cut a hole in the bottom of the lid, approximately 10-12 mm. and, using a burner, solder the cap to the tube with the thread facing up so that you can then screw the filter onto the bottle.

In this case, for obvious reasons, I would not recommend using glue, which is why I took a burner. For a more aesthetic appearance, I covered the filter with colored strips of self-adhesive film, although this is an individual matter. We make markings in the bottom of the tube for holes from which the filtered water will flow, and drill.

Water filter test

So, the filter is ready. To demonstrate it, I filled a bottle with water from a rusty barrel and, screwing a filter onto it, poured this water into a clean jar.

The difference is obvious. This, of course, is not ideal sterility, and it does not flow as quickly as we would like, but in an emergency, I think it is still better than without a filter at all.

Similar master classes

Particularly interesting

Comments (0)