Full Size Metal Barrel Grill

Have you seen the prices for a normal grill? So I saw it and decided that I would make it myself from an ordinary metal barrel, which would definitely be much cheaper. In my opinion, it turned out very beautifully, and most importantly, reliable. I'll tell you in more detail how I did it...

Since I plan to carry the grill on the back of a pickup truck, and I don’t have much storage space, I used a 75 liter barrel as a base. This volume is quite rare. Most stores will offer you 50, 100 and 200 liters. Sometimes you can find 60 liters, which is also great luck.

Materials I used:

Of course, you need a lot of materials, but I love working with metal, so that didn’t stop me. If you cannot get a 75 liter barrel, you will have to recalculate the materials for it, which will not be difficult if you understand the problem.

The first step is to cut the barrel lengthwise into 2 even halves. It is important to maintain accuracy, since otherwise each further section of a corner or rod will have to be measured locally, which will complicate the task. After marking, I cut everything with a grinder.

Next you need to make 2 frames from a narrow corner. You will need 4 pieces of 62.5 cm and 4 pieces of 39.5 cm. I cut the ends of the blanks at 45 degrees. I place the scraps on a flat surface, check them with a square and weld them.

Next, I install the frames on the barrel halves and weld them at the corners. The barrel is thin, so you can burn through the metal. To avoid making holes, I cook in dots.

In one of the halves of the barrel, I cut out an arbitrary but neat window with a grinder, through which air will then enter to maintain the heat. It will also help with ash disposal. I don’t throw away the cut metal; it will still be needed for the door.

On the other half you need to make a window for the chimney. It is cut in the center. You can cut it even less than mine, since the smoke will still escape through a thin tube.

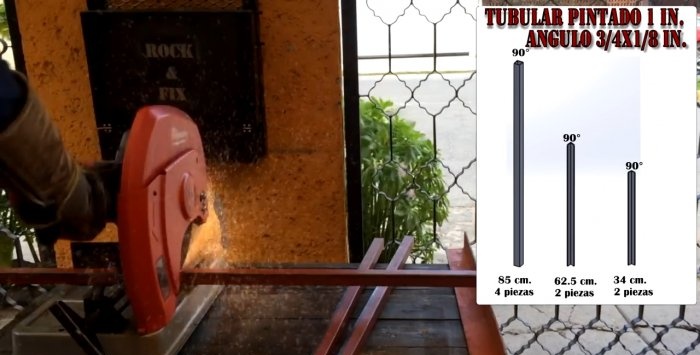

Next I prepare the stand. I cut 4 legs from a square with a section of 25x25 mm, 85 cm each. You will also need 2 pieces from a thin corner of 62.5 cm and 2 of 34 cm. I cut the corners and the square at 90 degrees.

I boil the thin corner between the legs. For accuracy I use 90° magnetic templates. The distance from the edge is 25 cm.

I weld the resulting legs with jumpers to the bottom of the barrel with a large window.It is very important to maintain accuracy here.

I install the almost finished grill on the rack and add long jumpers. This is already easier.

Now I move on to a folding side shelf with a folding stand. To do this, you will need to prepare a square frame from a narrow corner. I cut 4 pieces at 45 degrees, 33 cm each, and weld them together.

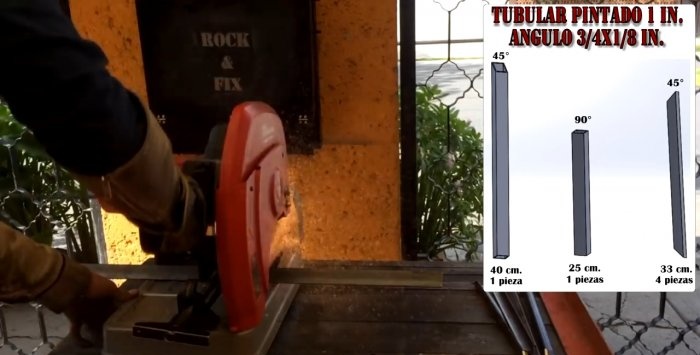

I'm preparing a folding stand. For this you will need to cut a 25x25 mm square. One piece is 40 cm, and the second is 25 cm. For a larger piece, you need to cut one end at 45 degrees. I weld them into a T-shaped stop. The side with the cut corner should be the front side.

Now I weld the shelf frame to the side of the grill through 2 door hinges. And then I fix the stop to it, also through 2 loops.

I cut a 34 cm piece from the wide corner. It will stop the leg of the folding shelf. I try it on and weld it.

Now it's time for the grid. I cut a narrow corner for the frame. You need 2 blanks of 58.5 cm and 2 of 35.5 cm. Everything is at 45°, but now I make the acute angle on the cut the other way around, so that the frame is external and not internal, like the previous ones. I also immediately prepare the rods for the grate. I used 17 rods. After preparation, welding begins again.

I install the grate and weld the grill lid through the 2 door hinges. Everything needs to be double-checked to ensure it closes completely.

I'm making a handle for the lid. First, I prepare a piece of a wide angle 15 cm long, and then I weld 2 strips of 14 cm each to it at 90°. At their ends I made holes for bolts, so that later I could hold the wooden handle. I weld the handle into the lid on the right.

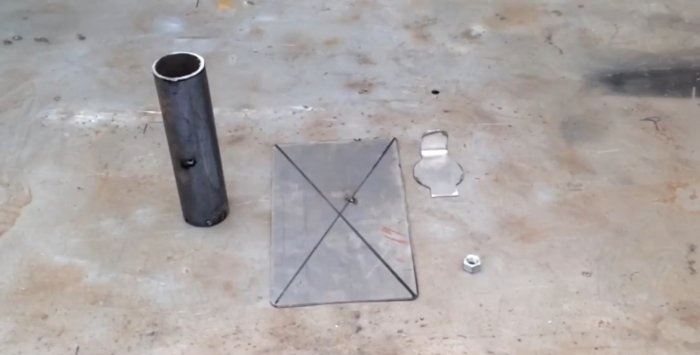

From the corner of a metal sheet 0.7 x 0.6 m I cut off a patch covering the window in the chimney cover. I make a hole in its center and weld a pipe. You also need to weld a nut to its edge.It is necessary to preserve the thread, since the damper will then be held on it. I applied the patch to the window, made 2 holes through it and the walls of the lid, then tightened everything with bolts and nuts.

I'm preparing the bottom grate for charcoal. To do this, I weld a frame from a rod. I use 2 blanks measuring 60 cm and 2 each 33 cm. I insert short rods between long ones. Next, I cut the steel sheet into strips 6 cm wide. 10 strips come out. Of these, 4 are by 60 cm, and 6 are shorter, since I already took material for the chimney patch from this sheet. I weld the strips crosswise, intertwining them with each other, leaving a gap for air. I also bend 2 handles from 30 cm rods and weld them on the sides of the grate bars.

Now we place the gratings sequentially for clarity.

Now I make a large side handle from a bent rod 60 cm long. I weld it along the entire length of the side to the bottom of the grill. I also immediately attach the rings for the chain. One is on the bottom and the other is on the lid.

Once the main metal parts are in place, it's time to paint. You only need to use thermal paint. An aerosol can was enough for me.

I cut the board into 3 pieces of 32 cm and 3 of 61 cm. I begin to cover the shelf on the side and on the counter, which was made from the lintels. To fasten, I drill through the board and the corner and tighten everything with a bolt and nut. The outer planks are a little wider, so they need to be trimmed. I also take a 14 cm handle and fix it with bolts to the lid handle.

I cut the damper for the chimney from a strip of strip from the bottom grate. It is secured with a bolt to a nut previously welded on the pipe.

Now, using furniture hinges and rivets, I mount the previously cut door from the bottom. It could have easily been welded, but I no longer had large hinges, everything went to the lid and folding shelf.

To keep the door closed, I put a padlock strap on it. I used rivets here too.

Now everything is ready, you can install the bars and the limiting chain.

It turned out quite well. I chose good paint so it holds up even after testing the grill. For those who will do the same, I would like to advise you to choose a thicker metal for the grates. I'll probably have to digest them later. Fortunately, everything is removable and there is an hour and a half of work there.

Required materials

Since I plan to carry the grill on the back of a pickup truck, and I don’t have much storage space, I used a 75 liter barrel as a base. This volume is quite rare. Most stores will offer you 50, 100 and 200 liters. Sometimes you can find 60 liters, which is also great luck.

Materials I used:

- barrel 75 l (0.39 by 0.62 m);

- corner 10x10 mm – 9.5 m;

- square 25x25 mm – 4.2 m;

- corner 25x25 mm – 0.5 m;

- smooth rod 12 mm – 9.5 m;

- metal strip 30 mm – 0.3 m;

- thick tin or sheet metal 0.7 x 0.6 m;

- door hinges for welding - 6 pcs.;

- furniture hinges – 2 pcs.;

- pipe 50 mm – 0.17 m;

- M6 bolts – 15 pcs.;

- nut M6 – 13 pcs.;

- chain rings – 2 pcs.;

- metal chain – 1 m;

- board 10x120 mm – 2.8 m;

- wooden handle, like from a shovel - 0.14 m;

- strap for a padlocked door lock – 1 pc.

- heat-resistant paint – 1 can.

Of course, you need a lot of materials, but I love working with metal, so that didn’t stop me. If you cannot get a 75 liter barrel, you will have to recalculate the materials for it, which will not be difficult if you understand the problem.

Making a grill from a steel barrel with your own hands

The first step is to cut the barrel lengthwise into 2 even halves. It is important to maintain accuracy, since otherwise each further section of a corner or rod will have to be measured locally, which will complicate the task. After marking, I cut everything with a grinder.

Next you need to make 2 frames from a narrow corner. You will need 4 pieces of 62.5 cm and 4 pieces of 39.5 cm. I cut the ends of the blanks at 45 degrees. I place the scraps on a flat surface, check them with a square and weld them.

Next, I install the frames on the barrel halves and weld them at the corners. The barrel is thin, so you can burn through the metal. To avoid making holes, I cook in dots.

In one of the halves of the barrel, I cut out an arbitrary but neat window with a grinder, through which air will then enter to maintain the heat. It will also help with ash disposal. I don’t throw away the cut metal; it will still be needed for the door.

On the other half you need to make a window for the chimney. It is cut in the center. You can cut it even less than mine, since the smoke will still escape through a thin tube.

Next I prepare the stand. I cut 4 legs from a square with a section of 25x25 mm, 85 cm each. You will also need 2 pieces from a thin corner of 62.5 cm and 2 of 34 cm. I cut the corners and the square at 90 degrees.

I boil the thin corner between the legs. For accuracy I use 90° magnetic templates. The distance from the edge is 25 cm.

I weld the resulting legs with jumpers to the bottom of the barrel with a large window.It is very important to maintain accuracy here.

I install the almost finished grill on the rack and add long jumpers. This is already easier.

Now I move on to a folding side shelf with a folding stand. To do this, you will need to prepare a square frame from a narrow corner. I cut 4 pieces at 45 degrees, 33 cm each, and weld them together.

I'm preparing a folding stand. For this you will need to cut a 25x25 mm square. One piece is 40 cm, and the second is 25 cm. For a larger piece, you need to cut one end at 45 degrees. I weld them into a T-shaped stop. The side with the cut corner should be the front side.

Now I weld the shelf frame to the side of the grill through 2 door hinges. And then I fix the stop to it, also through 2 loops.

I cut a 34 cm piece from the wide corner. It will stop the leg of the folding shelf. I try it on and weld it.

Now it's time for the grid. I cut a narrow corner for the frame. You need 2 blanks of 58.5 cm and 2 of 35.5 cm. Everything is at 45°, but now I make the acute angle on the cut the other way around, so that the frame is external and not internal, like the previous ones. I also immediately prepare the rods for the grate. I used 17 rods. After preparation, welding begins again.

I install the grate and weld the grill lid through the 2 door hinges. Everything needs to be double-checked to ensure it closes completely.

I'm making a handle for the lid. First, I prepare a piece of a wide angle 15 cm long, and then I weld 2 strips of 14 cm each to it at 90°. At their ends I made holes for bolts, so that later I could hold the wooden handle. I weld the handle into the lid on the right.

From the corner of a metal sheet 0.7 x 0.6 m I cut off a patch covering the window in the chimney cover. I make a hole in its center and weld a pipe. You also need to weld a nut to its edge.It is necessary to preserve the thread, since the damper will then be held on it. I applied the patch to the window, made 2 holes through it and the walls of the lid, then tightened everything with bolts and nuts.

I'm preparing the bottom grate for charcoal. To do this, I weld a frame from a rod. I use 2 blanks measuring 60 cm and 2 each 33 cm. I insert short rods between long ones. Next, I cut the steel sheet into strips 6 cm wide. 10 strips come out. Of these, 4 are by 60 cm, and 6 are shorter, since I already took material for the chimney patch from this sheet. I weld the strips crosswise, intertwining them with each other, leaving a gap for air. I also bend 2 handles from 30 cm rods and weld them on the sides of the grate bars.

Now we place the gratings sequentially for clarity.

Now I make a large side handle from a bent rod 60 cm long. I weld it along the entire length of the side to the bottom of the grill. I also immediately attach the rings for the chain. One is on the bottom and the other is on the lid.

Once the main metal parts are in place, it's time to paint. You only need to use thermal paint. An aerosol can was enough for me.

I cut the board into 3 pieces of 32 cm and 3 of 61 cm. I begin to cover the shelf on the side and on the counter, which was made from the lintels. To fasten, I drill through the board and the corner and tighten everything with a bolt and nut. The outer planks are a little wider, so they need to be trimmed. I also take a 14 cm handle and fix it with bolts to the lid handle.

I cut the damper for the chimney from a strip of strip from the bottom grate. It is secured with a bolt to a nut previously welded on the pipe.

Now, using furniture hinges and rivets, I mount the previously cut door from the bottom. It could have easily been welded, but I no longer had large hinges, everything went to the lid and folding shelf.

To keep the door closed, I put a padlock strap on it. I used rivets here too.

Now everything is ready, you can install the bars and the limiting chain.

It turned out quite well. I chose good paint so it holds up even after testing the grill. For those who will do the same, I would like to advise you to choose a thicker metal for the grates. I'll probably have to digest them later. Fortunately, everything is removable and there is an hour and a half of work there.

Watch the video

Similar master classes

Particularly interesting

Comments (0)