Power bank from a broken tablet

It's no secret that the tablet's battery is very energy-intensive. Otherwise, how to “feed” such a giant, which has a large screen, powerful speakers and no less powerful Wi-Fi, Bluetooth and GPS modules... It is very unpleasant that these devices break down much more often and faster than others, which are not so useful and interesting gadgets. A fairly common cause of failure is a crushed screen. Due to its considerable size, it is this element, as the most fragile part in the entire structure, that is subject to external mechanical influence. A simple fall from the hands of a clumsy owner is enough... and who will manage to sit on it. It was just such a crushed tablet that they brought me recently for spare parts.

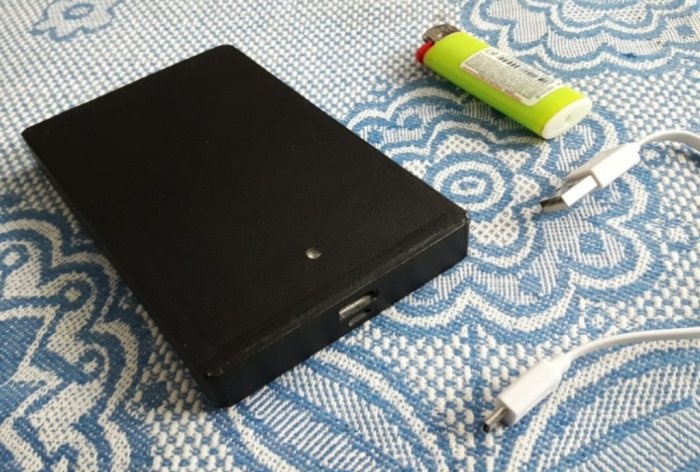

The device, according to its owners, was not even a month old. Ordering and purchasing a new screen, as well as paying a technician to replace the screen, almost doubled the cost of the tablet itself, so its owners wisely abandoned this idea. However, even from a broken tablet you can extract many useful and necessary things, and one of them is batteries.It is from these practically new batteries that I propose to assemble an external charger. Most tablets of this type usually have paired lithium batteries. Each of them has a 3.7 volt output and 7000 mA*h. By connecting these two batteries in parallel (plus to plus, and minus to minus), we get the same 3.7 volts at the output, but the capacity of such a double battery doubles - up to 14000 mA*h. These are very good indicators for an average external charger. You can safely charge even the most modern smartphone 3-4 times. The most problematic thing about this venture was getting the body to work. Well, I had to order it online charge controller for lithium batteries. I ordered not the cheapest, but not very expensive either - average.

The parcel arrived quite quickly.

Will need

- Tablet batteries.

- Charge controller for lithium batteries.

- Soldering iron, tin and flux.

- Double tape.

- Thin wires (preferably black and red).

- Scissors.

- Secondary glue and soda.

- Sheet of plastic (1.5-2 millimeters thick).

- Burner.

- Colored adhesive film (for decorative cladding).

- Flathead screwdriver.

- Ruler and marker.

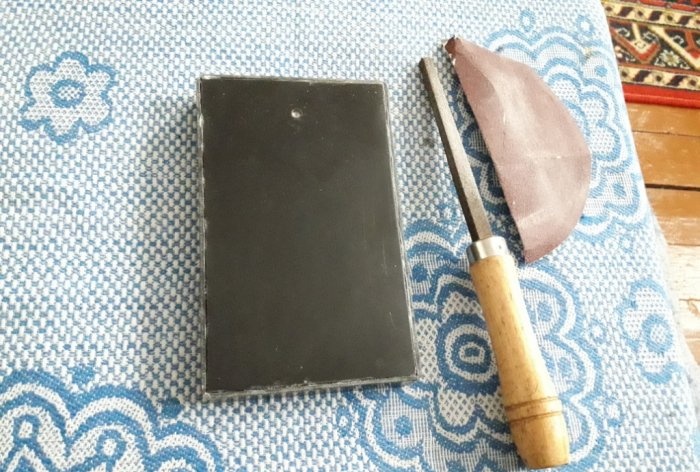

- Files.

Manufacturing Power bank

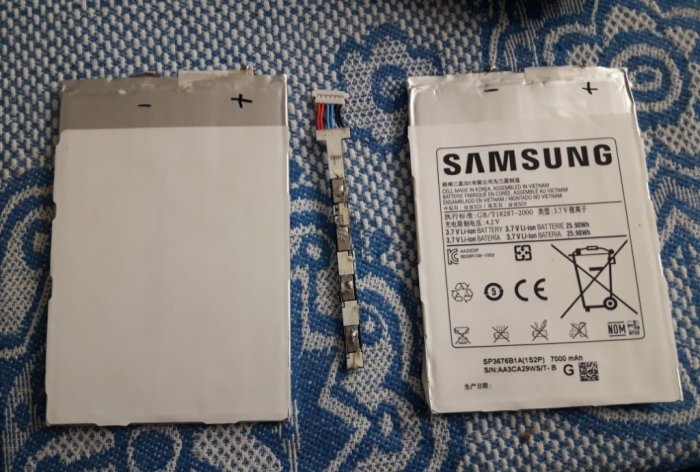

So, first you need to remove the batteries from the broken device. Using a flat-head screwdriver, remove the cover from the tablet. We disconnect the charge controller plug, to which the batteries are soldered, from the tablet board and remove the batteries along with the controller. We unsolder the batteries from the controller and remove the controller - maybe it will come in handy in the future.

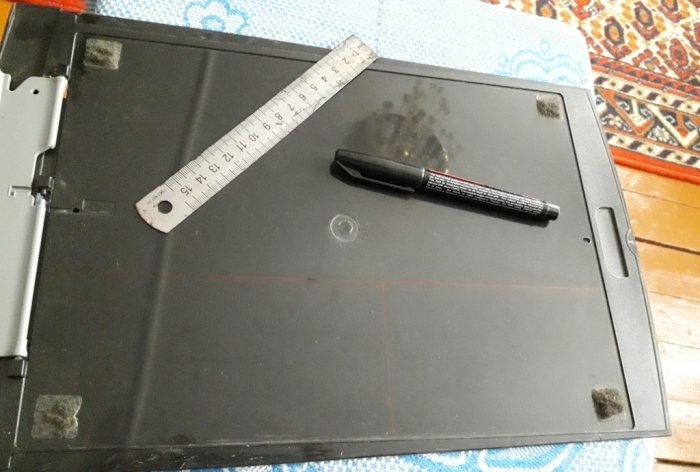

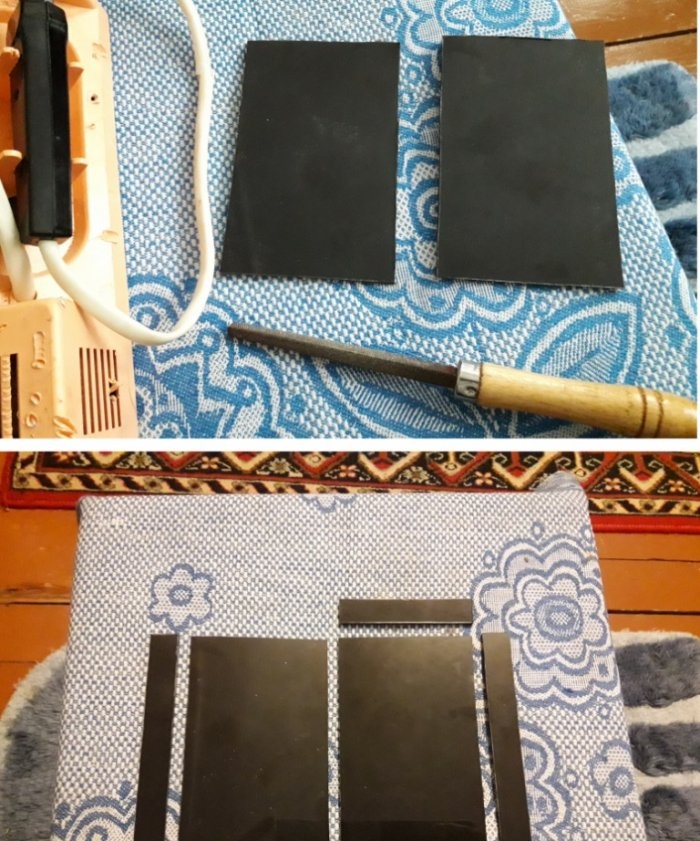

The main and, in my opinion, rather tedious job is to design the body. Let's start with him.Having selected a plastic of suitable thickness, I got down to business.

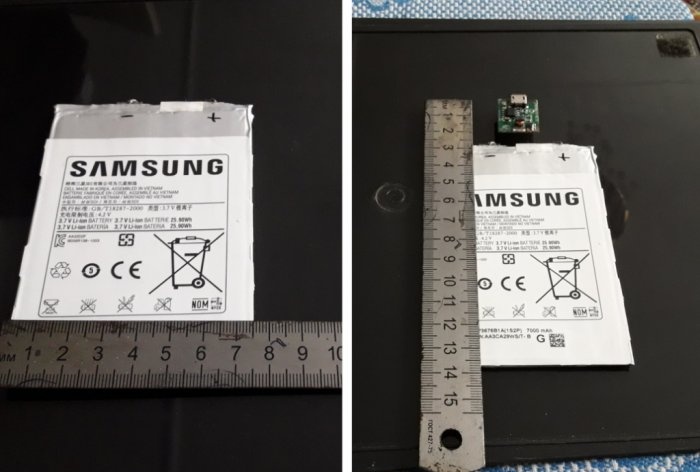

We measure the length and width of the battery, not forgetting about the additional space for the new charge controller and, using a ruler and marker, transfer the parameters to a plastic sheet.

The thickness of the future device is determined based on the thickness of the most voluminous part of all components.

Next, we cut out the blanks with the hot tip of the burner.

It was possible to cut it all out strictly along the drawn lines and then simply remove the melted edges with a file, but I decided to save time and cut it with small margins, so as not to fumble with the file later. I just took powerful scissors and trimmed the plastic blanks along the lines... So, the body blanks are ready.

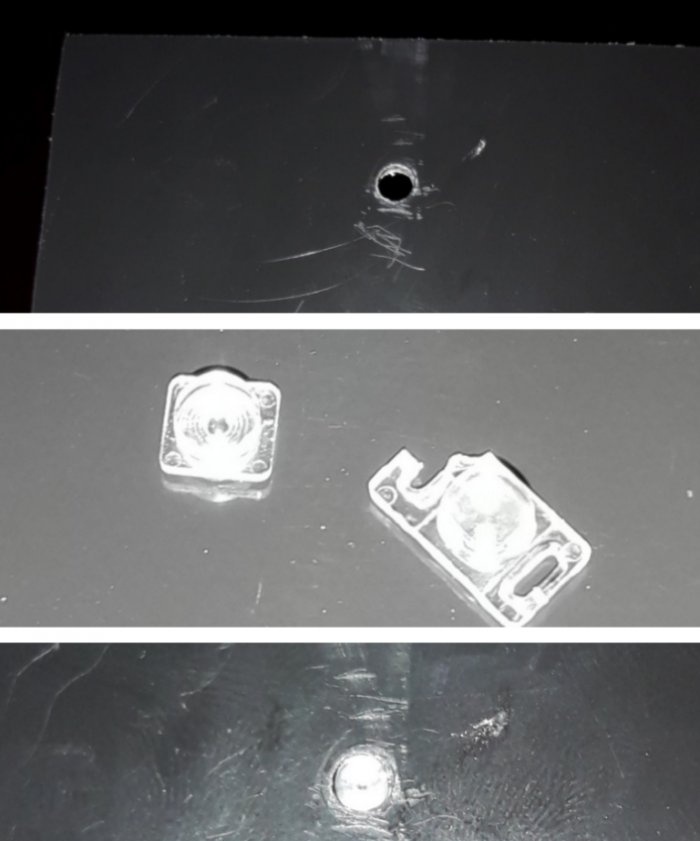

Now, on one of the front ends, mark with a marker where the input and output connectors of the device will be located. Again, using a burner, we cut out approximate holes and finish them with a thin file.

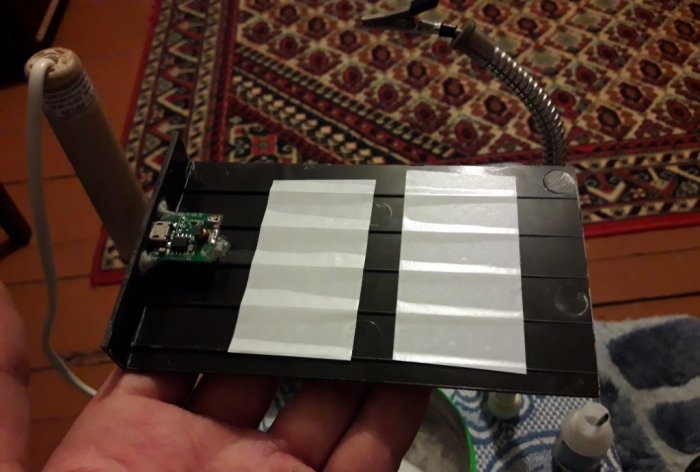

Now let's prepare the battery. Namely, we glue one exactly to the other using double tape, solder the contacts in parallel - plus to plus, minus to minus (here you need to be extremely careful!) and solder them to the soldered wiring contacts. Red is positive, black is negative. This is to avoid confusion.

Now, using a second of glue and soda, we glue the charge controller to the corresponding holes in the previously prepared end wall of the case.

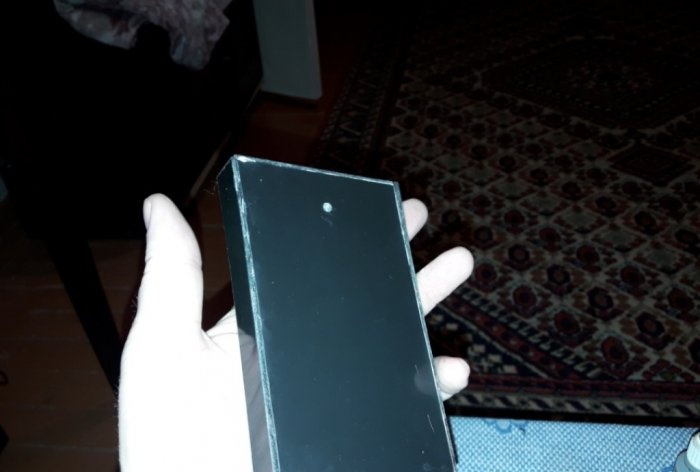

Next, let's move on to the indicator. This controller does not have an on/off key, and there is no display showing the charge level. Instead, there are two microdiodes - blue and red. Flashes red when the device itself is charging, and stays steady when charging is complete.Blue lights up evenly when the device is charging a gadget, and goes out when the charging gadget is fully charged. To bring this indication out, through the blind and light-proof plastic, I made a hole in the top cover of the case, in the approximate location of the indicators. Then I glued a light diffuser from the camera flash (picked out from the same tablet) into this hole. It turned out to be a very good and neat indicator.

Now we glue the end with the controller glued into it to the bottom cover of the case and stick double tape on the inside (bottom).

We place the batteries on tape and solder the positive and negative wires to the corresponding terminals of the controller (terminals B+ and B-). It is important not to confuse the polarity, otherwise the controller will burn out instantly - I already had bitter experience...

Next, we assemble the remaining parts of the body together, gluing everything together with instant glue.

There is very little left; File off all protruding and sharp corners from the ends, sand with light sandpaper, and cover the product with adhesive film of any color you like. For example, I covered it with matte black.

In the store, a Power bank with such a charge capacity is very expensive, but in our case, it cost us the cost of a charge controller (2 dollars) and a couple of hours of work... Moreover, it turned out to be no larger and thicker than a charger from store, factory assembled - the size of a palm, but very energy-intensive.

If you connect a USB splitter to it, it can greatly help you and several other people during a long trip, outdoor recreation, or when there is a power outage during a repair, for example.

Watch the video

Similar master classes

Particularly interesting