How to make a modern country chair with your own hands

Currently, the furniture industry has literally flooded the corresponding sector of the market with a variety of products from all kinds of materials and all existing styles, from retro to techno. Many people are attracted to wooden furniture, but it is now too expensive for most people who want to buy it.

But why not try to make it yourself, at least the simplest in design, not difficult to manufacture, and requiring ordinary tools? Undoubtedly, this type of furniture is a country or garden chair made of wooden beams with a cross-section of 8×8 cm or better 10×10 cm.

In order to make this type of furniture, it is enough to have minimal skills in working with carpentry tools and have a general understanding of the properties of wood as a material for mechanical processing.

The most suitable materials for making a country chair are oak, beech, pine, walnut, birch, and ash.Their wood, which has undergone high-quality drying, is quite hard and therefore durable, is not afraid of moisture, is well processed and, importantly, has a beautiful texture. Linden and alder can be used to make light-duty parts.

Marking and preparing workpieces

Having decided on the dimensions of the chair, we measure the required length on the selected beam, taking into account the processing, and mark it using a construction tape, a metal triangle, a suitable pencil or marker.

Using a pendulum saw, we cut the timber into pieces, while simultaneously trimming their ends. For the design of the chair we have chosen, you will need 16 square-shaped large-section blanks and 2 bars with sides half the size of the main blanks.

To give a neat appearance and improve the quality of future assembly, we subject each workpiece to a milling process on all sides, including the end parts.

In the blanks that are intended to form the seat frame, in three we select grooves in the floor of the wood at the ends, using a circular saw or a hand saw, and in two - in a quarter of the wood, for which we need an electric scraper and a hand chisel to fine-tune the geometry of the grooves.

Assembling a country chair

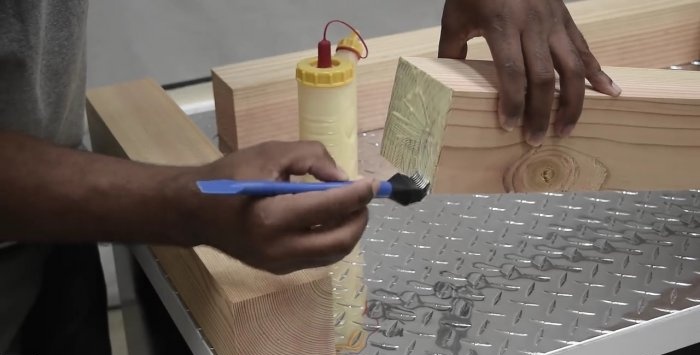

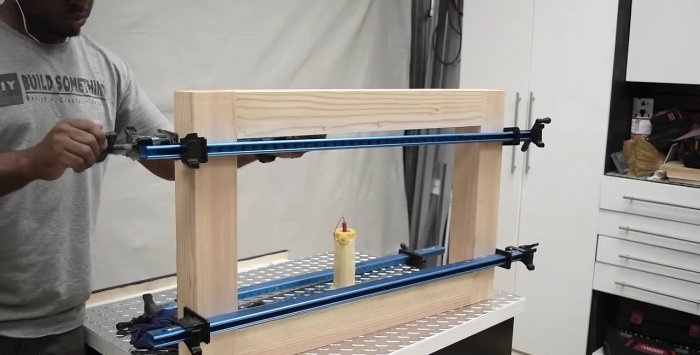

We assemble the sides of the product with glue, lubricating it with a brush, the ends and mating parts of the mating parts, and tighten them using clamps adjustable in length, preferably on a flat horizontal surface.

To mechanically strengthen the connections in their centers, use an electric drill and a suitable drill to prepare blind holes for the heads of the coupling screws. Then, using a smaller drill, we set the direction of the coupling screws, which we screw in using a screwdriver.

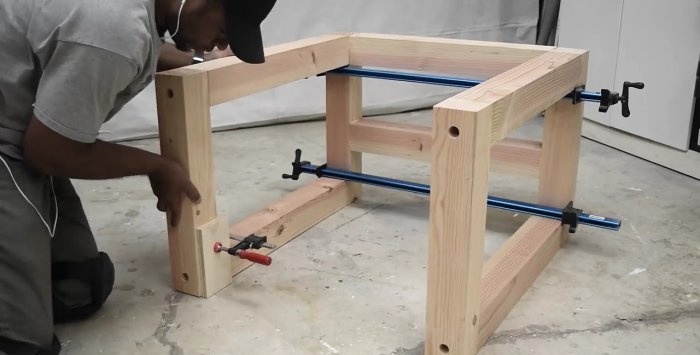

Next, we rigidly glue the side panels together using the upper back cross member at the level of the armrests in height and flush with the rear legs and the rear cross member of the seat frame at a certain height using pre-prepared templates from multi-layer plywood. To prevent them from moving, we secure them with clamps.

We set the crossbars according to the templates, having previously lubricated the ends and the corresponding places on the legs with glue. Using a metal triangle, we check that the right angle is maintained and, if necessary, adjust the crossbars.

We tighten the structure in the direction of the crossbars with length-adjustable clamps and strengthen the crosshairs with tension screws.

We close all the holes for the screw heads with wooden glue plugs, sawing off the excess flush with the side surfaces.

Now we install the longitudinal side elements of the seat frame with grooves in a quarter of the wood at the level of its transverse elements.

We fix a beam of smaller cross-section into the grooves with glue, fix it with a clamp and screw them with two or three screws each to the transverse elements of the seat frame.

On them we lay three longitudinal beams with glue on them with grooves in half the wood, using templates that set the same distance between them, and temporarily secured with clamps.

Each of the three middle bars of the seat frame is fastened on both sides from below to the small bars with two screws screwed in flush (to do this, we pre-drill sockets for the screw heads using a drill).

Since the outer bars of this element of the garden chair were not completely secured, we remove them, coat the grooves with glue and put them in place, securing them with clamps until the glue dries completely.The frame of our product is fully assembled, and all its elements are securely fastened with glue and screws, forming a strong and rigid power structure.

We finally process all the edges of the frame with a grinding machine to obtain even and smooth surfaces.

We carefully wipe them with a slightly damp cloth to remove small particles and wood dust and let the wood dry completely.

The last operation is coating with varnish, which will protect the surface of the wood from moisture, make it easier to care for the furniture and emphasize the natural texture of the wood.

All that remains is to install the cushions for the back and seat after the varnish has dried.

The chair is designed for both a child and an adult, and even for a father or mother with a daughter or son on their lap.

Concluding remarks

When working on a country chair, we must not forget about the presence and serviceability of shields and protective elements over cutting tools. You should also wear long sleeves with tight closures at the wrists. You should wear gloves on your hands and safety glasses on your eyes. A respirator will also help to protect yourself from fine wood dust and varnish fumes, which are not harmless to the human body.

For safety and greater aesthetics, it would not hurt to smooth out the sharp corners, especially if there are small children in the family, and the clothes will also serve a purpose. And under the legs it is worth stuffing rubber or plastic material so that moisture does not penetrate the wood and cause it to rot.

In order for the chair to last as long as possible and not lose its operational and aesthetic qualities, during precipitation and in the winter it is advisable to put it under a roof and cover it with at least plastic film so that dust and other pollutants floating in the atmosphere do not settle.

Watch detailed video

Similar master classes

Particularly interesting

Comments (4)