Quick-release eccentric vice

It is impossible to imagine an auto repair shop or home workshop without a bench vise, regardless of what material you have to work with: metal, plastic or wood. Usually, a classic vice with a crank is used everywhere, which slowly clamps and releases parts.

It is absolutely easy and in a short time to make a homemade metal vice with an eccentric clamp, which is compact in size and also allows you to quickly and reliably fix workpieces. The speed of the vice will be especially useful when performing large volumes of work that are characterized by uniformity and monotony.

You can make the simplest metal vice with an eccentric clamp with your own hands from inexpensive scrap materials - leftover scrap metal, which can almost always be found in a home workshop or garage. Therefore, we will not dwell on the materials. If there is a need to specify their features, we will clarify this during the work process.

For work we will need the most common tools:

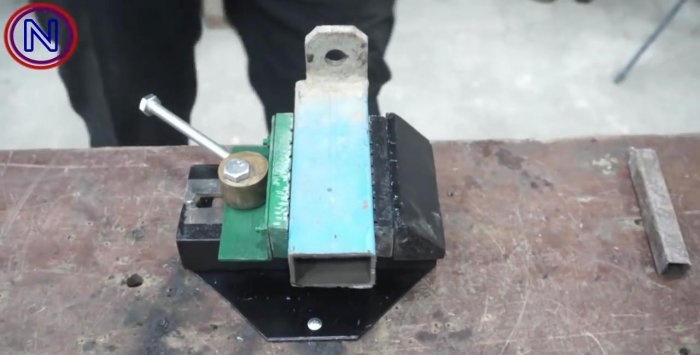

To make the work go smoothly, it doesn’t hurt to mentally imagine the end result of the work we are just starting: a ready-made quick-clamping eccentric vice, delighting us with its compactness, color variety and amazing ability to quickly and reliably clamp any workpiece.

Well, now let’s get to work so that the dream turns into reality. We find the rest of the useless channel, mark it with a ruler and marker and cut off the required piece using a grinder. It will become the basis for the movable and fixed jaws of our vice.

From a suitable equal angle corner after marking, we cut off two pieces of equal length, which in a vice will become the base of the jaws of our homemade vice.

In the middle of the shelf of one of the corners - the future movable jaw of the vice - we mark the center of the hole, which we drill on a drilling machine.

On the crosspiece of the channel blank, along its central axis, closer to one end, we mark the boundaries of the slot along which the movable jaw of our vice will move. Mark the marked points and drill holes, which will be the ends of the slot.

Using a grinder, we cut out a strip of metal in the channel bridge between these two holes and knock it out with the tapering head of a hammer. This slot will set the limits of movement of the movable jaw of the vice.

Using a grinder, we cut two pieces from a suitable metal strip, the length of which is equal to the width of the corner shelf. They will serve as limiters for the movable jaw as it moves along the slot.

Next, we connect the angle and channel using a bolt and nut in the position that they will occupy in the finished vice.

We clamp this structure in a bench vice and weld limiters to the corner transversely on both sides of the channel, holding them with pliers. To avoid accidentally welding them to the channel flanges, we place a thin piece of rubber, plastic or other dielectric material between them during welding.

Then, from a used hammer with a round head, we cut off a cylindrical blank with a grinder approximately equal in height to the diameter - the blank for the future eccentric clamp.

We mark a point at its end with some eccentricity - an indentation from the central longitudinal axis of the cylinder. Using the mark, we drill a through hole parallel to the axis of our workpiece.

From a thick strip of metal, after marking, we cut out two pieces of length and height equal to the shelf of the equal-flange angle. These are future jaw pads for quick-release vices.

We drill two holes in these pads in the center closer to the edges. We unfold them from the front side under the heads of the mounting screws. Using a grinder, we make a notch and clean them. We test the quality of fastening the linings to the corner flanges (jaws) with two bolts and nuts.

We weld one corner (fixed jaw) transversely to the channel web on the side opposite the slot. We reinstall the pads on the fixed and movable jaws and finally screw them in place, using a wrench and a screwdriver.

From fairly thick metal we cut out a strip equal in size to the length of the corner, and in width to the distance between the ends of the shelves diagonally. We also weld it to ensure the strength and rigidity of the fixed jaw.

Now we take a thicker strip of metal and drill a hole at one end and cut a thread in it using a tap.Then we cut off a piece from it with a threaded hole of a rectangular shape, slightly different from a square.

This homemade rectangular nut will hold the eccentric on the movable jaw, and allow them to move along the channel web (guide) in one direction or another.

To prevent the nut from rotating under the channel jumper, we cut off and weld two limiting guide rods on both sides of it longitudinally along the entire slot with a small gap.

In the side of the eccentric, approximately in the middle of its height, we drill a blind hole and cut a thread in it for fastening the handle.

We assemble the movable jaw of the vice with pre-welded stops, screwing the finished cover with notches to the corner with two bolts.

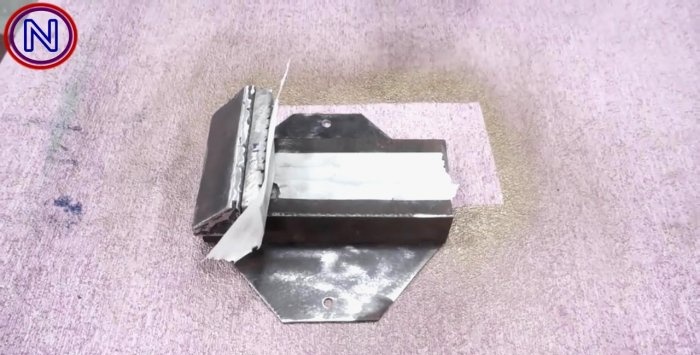

We find a piece of sheet iron of sufficient thickness to ensure rigidity. We mark on it the contours of an octagonal-shaped base with two marks for holes for fastening. Using a grinder we cut it out.

We weld a channel (guide) with a fixed jaw to it. We process welds and surfaces with a grinder to remove rust, metal deposits, roughness and rounding of edges.

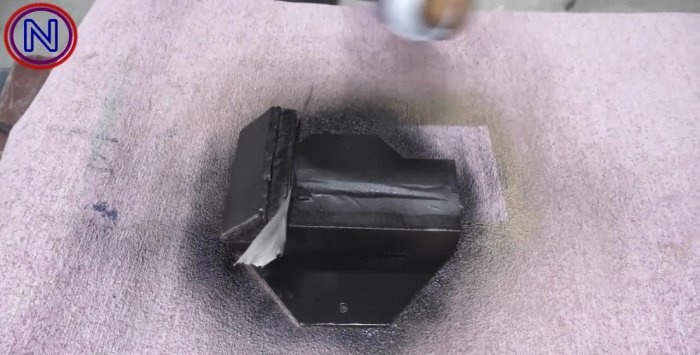

We seal the sponge overlay and the longitudinal slot with a margin on the sides with construction tape.

Using an aerosol can, we paint the base, guide and fixed jaw black, the movable jaw (except for the lining) with green paint, and the eccentric with bronze.

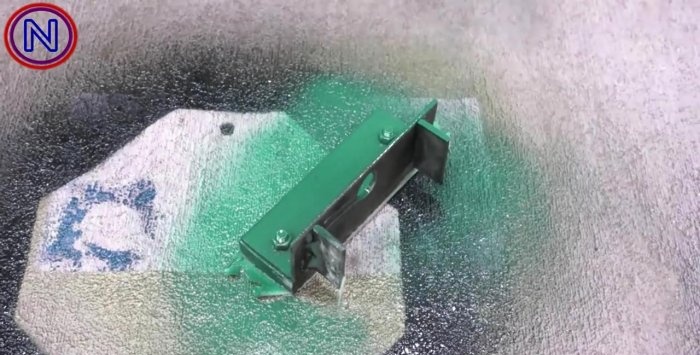

After the paint has dried and the tape has been removed, all parts of our eccentric vice are basically ready and just waiting for final assembly.

To do this, we just need to install the eccentric and the movable jaw on the guide, pass the bolt through the holes and install a rectangular nut from below under the guide and screw the bolt into it.

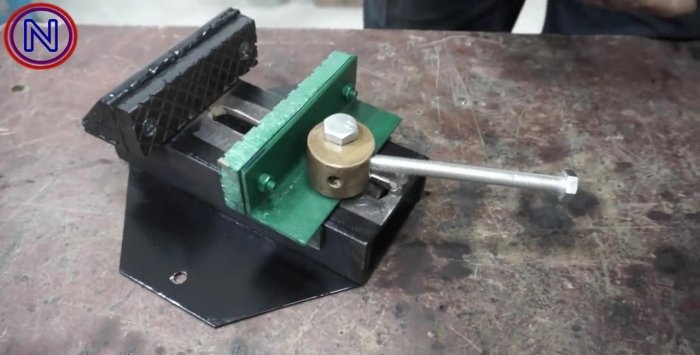

We screw the handle into the eccentric on the side, and secure the base of the vice with two screws to a strong wooden base. Our in-house made quick-release eccentric vices are fully ready to use.

With their help, with one movement of the eccentric handle, you can secure any workpiece in them quickly, reliably and without unnecessary effort.

Since you will have to work with an angle grinder, a welding machine, or a drilling machine, you must use personal protective equipment, at least goggles to protect your eyes and gloves for your hands.

To ensure that the moving parts of the eccentric vice work without jamming, they can be lubricated from time to time with graphite grease, and the eccentric lever can be equipped with a wooden handle for convenience.

It is absolutely easy and in a short time to make a homemade metal vice with an eccentric clamp, which is compact in size and also allows you to quickly and reliably fix workpieces. The speed of the vice will be especially useful when performing large volumes of work that are characterized by uniformity and monotony.

You can make the simplest metal vice with an eccentric clamp with your own hands from inexpensive scrap materials - leftover scrap metal, which can almost always be found in a home workshop or garage. Therefore, we will not dwell on the materials. If there is a need to specify their features, we will clarify this during the work process.

For work we will need the most common tools:

- welding machine;

- grinder with cutting disc;

- drill press or drill;

- thread tap:

- hammer;

- mites;

- bench vise, etc.

Let's start making a vice

To make the work go smoothly, it doesn’t hurt to mentally imagine the end result of the work we are just starting: a ready-made quick-clamping eccentric vice, delighting us with its compactness, color variety and amazing ability to quickly and reliably clamp any workpiece.

Well, now let’s get to work so that the dream turns into reality. We find the rest of the useless channel, mark it with a ruler and marker and cut off the required piece using a grinder. It will become the basis for the movable and fixed jaws of our vice.

From a suitable equal angle corner after marking, we cut off two pieces of equal length, which in a vice will become the base of the jaws of our homemade vice.

In the middle of the shelf of one of the corners - the future movable jaw of the vice - we mark the center of the hole, which we drill on a drilling machine.

On the crosspiece of the channel blank, along its central axis, closer to one end, we mark the boundaries of the slot along which the movable jaw of our vice will move. Mark the marked points and drill holes, which will be the ends of the slot.

Using a grinder, we cut out a strip of metal in the channel bridge between these two holes and knock it out with the tapering head of a hammer. This slot will set the limits of movement of the movable jaw of the vice.

Using a grinder, we cut two pieces from a suitable metal strip, the length of which is equal to the width of the corner shelf. They will serve as limiters for the movable jaw as it moves along the slot.

Next, we connect the angle and channel using a bolt and nut in the position that they will occupy in the finished vice.

We clamp this structure in a bench vice and weld limiters to the corner transversely on both sides of the channel, holding them with pliers. To avoid accidentally welding them to the channel flanges, we place a thin piece of rubber, plastic or other dielectric material between them during welding.

Then, from a used hammer with a round head, we cut off a cylindrical blank with a grinder approximately equal in height to the diameter - the blank for the future eccentric clamp.

We mark a point at its end with some eccentricity - an indentation from the central longitudinal axis of the cylinder. Using the mark, we drill a through hole parallel to the axis of our workpiece.

From a thick strip of metal, after marking, we cut out two pieces of length and height equal to the shelf of the equal-flange angle. These are future jaw pads for quick-release vices.

We drill two holes in these pads in the center closer to the edges. We unfold them from the front side under the heads of the mounting screws. Using a grinder, we make a notch and clean them. We test the quality of fastening the linings to the corner flanges (jaws) with two bolts and nuts.

We weld one corner (fixed jaw) transversely to the channel web on the side opposite the slot. We reinstall the pads on the fixed and movable jaws and finally screw them in place, using a wrench and a screwdriver.

From fairly thick metal we cut out a strip equal in size to the length of the corner, and in width to the distance between the ends of the shelves diagonally. We also weld it to ensure the strength and rigidity of the fixed jaw.

Now we take a thicker strip of metal and drill a hole at one end and cut a thread in it using a tap.Then we cut off a piece from it with a threaded hole of a rectangular shape, slightly different from a square.

This homemade rectangular nut will hold the eccentric on the movable jaw, and allow them to move along the channel web (guide) in one direction or another.

To prevent the nut from rotating under the channel jumper, we cut off and weld two limiting guide rods on both sides of it longitudinally along the entire slot with a small gap.

In the side of the eccentric, approximately in the middle of its height, we drill a blind hole and cut a thread in it for fastening the handle.

We assemble the movable jaw of the vice with pre-welded stops, screwing the finished cover with notches to the corner with two bolts.

We find a piece of sheet iron of sufficient thickness to ensure rigidity. We mark on it the contours of an octagonal-shaped base with two marks for holes for fastening. Using a grinder we cut it out.

We weld a channel (guide) with a fixed jaw to it. We process welds and surfaces with a grinder to remove rust, metal deposits, roughness and rounding of edges.

We seal the sponge overlay and the longitudinal slot with a margin on the sides with construction tape.

Using an aerosol can, we paint the base, guide and fixed jaw black, the movable jaw (except for the lining) with green paint, and the eccentric with bronze.

After the paint has dried and the tape has been removed, all parts of our eccentric vice are basically ready and just waiting for final assembly.

To do this, we just need to install the eccentric and the movable jaw on the guide, pass the bolt through the holes and install a rectangular nut from below under the guide and screw the bolt into it.

We screw the handle into the eccentric on the side, and secure the base of the vice with two screws to a strong wooden base. Our in-house made quick-release eccentric vices are fully ready to use.

With their help, with one movement of the eccentric handle, you can secure any workpiece in them quickly, reliably and without unnecessary effort.

Notes at the end

Since you will have to work with an angle grinder, a welding machine, or a drilling machine, you must use personal protective equipment, at least goggles to protect your eyes and gloves for your hands.

To ensure that the moving parts of the eccentric vice work without jamming, they can be lubricated from time to time with graphite grease, and the eccentric lever can be equipped with a wooden handle for convenience.

Watch the video

Similar master classes

Particularly interesting

Comments (5)