DIY boron machine

The device of the bur machine is not the most complicated; motor and start button in the housing. But bur machines come in different types. It all depends on the manufacturer. Many manufacturers also install a button to reduce speed. This is not an electric button, but pure mechanics - the button presses on a metal rod, which in turn slows down the rotating shaft with a collet chuck and a drill or cutting disc fixed in it. There are models with electronic speed switches. There are also pneumatic machines, such as those used by dentists. Such machines do not operate on electricity, but on the energy of compressed air. They are, of course, the most resourceful and the most powerful...

The most important part in a drilling machine, of course, is the electric motor. The engine for an average price and quality bur machine should produce approximately 16-18 thousand revolutions per minute. This is quite enough to process wooden blanks and crafts, bone, plastic, aluminum and duralumin, and is also suitable for processing soft minerals and stones. Engines starting from 20 thousand revolutions per minute are already capable of working with solid minerals and metals...It so happened that I came across a working engine from a remote-controlled toy motor boat, which was given to me for spare parts. Repairing this toy did not seem cost-effective; The electronics burned due to water ingress cost little less than the toy itself. However, its engine itself was not damaged. The engine there was 9 volts, quite large, powerful and quite revving - this is understandable, it was installed in a toy to quickly push it through the water, and for this purpose the motor must be powerful and revving.

Unfortunately, I do not have a device for measuring revolutions, but from the sensations when trying to stop the shaft of a running engine with my fingers, it became clear that it could well be used to make a simple drill machine, which, at least, is suitable for working with wood, plastic and bone will definitely do.

Will need

- An engine from a toy boat (or a similar one, with the same characteristics - 9-12 volts).

- A suitable voltage power supply or adapter to power the motor.

- Plug and connector for it.

- Start button.

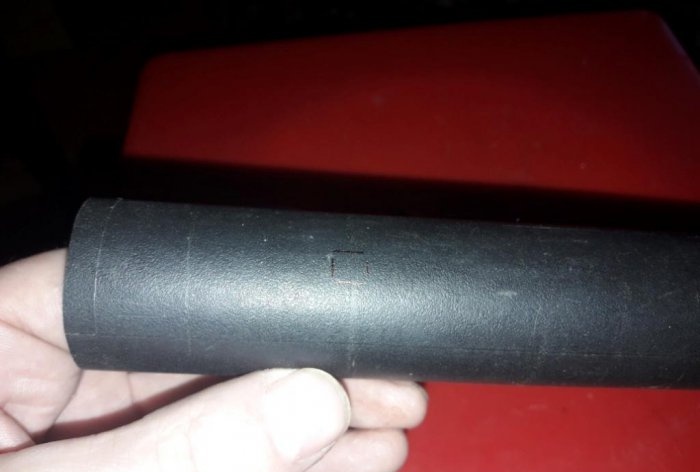

- Pipe, internal diameter for the engine, and length cm. 15-17.

- Sheet plastic, 2-3 mm thick. (for ends).

- Secondary glue and soda.

- Miniature collet chuck, with a 3.17 mm connector. and clamp from 0.3 to 3.5 mm.

- Any copper insulated wires.

- Soldering iron, with tin and flux.

- File.

- Sandpaper, medium grit.

- A knife with a strong and sharp blade (preferably a technical scalpel).

- Emery machine or burner (for cutting plastic).

Making bur machine

First you need to check the motor itself - it should work evenly, without emitting odors, and not heating up immediately when connected.You can try on a cartridge for it.

In the future, slight heating during operation is normal. Also, using a battery and LED, you can check the functionality of the start button and the plug with its connector; It is better to identify and eliminate the malfunction at the beginning of assembly rather than at the end. Since we plan to have a simple machine, without any speed switches, the start button can be the simplest, one-stroke, like a key on, say, a remote control. That is; pressed it - it works, released it - it stopped working. Moreover, it is also safe; in an unforeseen, unwanted situation, we ourselves, involuntarily, will remove our finger from the button, thereby avoiding possible injury or damage to surrounding objects. You can choose a plug with a connector at your discretion, the main thing is that they fit together and are working.

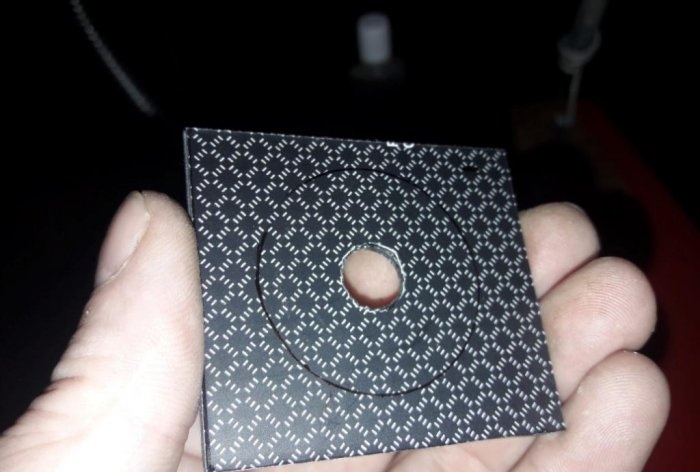

So, we take a pipe of a suitable (or approximately suitable!) diameter. I cut a piece of pipe from an old, unnecessary vacuum cleaner. Let's try the engine in it. If the pipe is a little too big, that's okay (the main thing is that it's not too small!), just wrap a few turns of insulating tape around the motor to make it the right size. In addition, soft and flexible electrical tape will act as a kind of shock absorber - it will dampen and absorb vibrations that inevitably form during engine operation. If the pipe and the engine fit together, let's work on the ends. To do this, we measure the width of the place where we will attach the engine to the end, drill a suitable hole in the plastic sheet and insert the engine into it. It will turn out like this:

Next, insert the motor into the pipe until the plastic sheet rests against the end. Draw a marker along the outline.

We remove the sheet from the engine and, using a burner or an emery machine, cut out a round end wall along the contours. We do the same for the rear end.

Only here the situation is simpler - here it is not necessary to calculate the center where to make the hole for the plug connector. We measure the width of the connector and drill a suitable hole approximately in the middle of the finished end plate. Now let's move on to the button. We will choose the most convenient place for ourselves where it will be located. We measure the parameters of the button and transfer them to the selected location.

Cut (or drill) a suitable hole.

Next, take a double copper wire, 20 cm long.

We determine its middle, in this middle we cut one of the wires in half, solder the wire cut in the middle to the button contacts. The result was a two-core wire, with a breaker in the middle on one of the wires. Like this:

Now we thread the wire with the button into the pipe, find the hole for it with the button and insert the button into this hole from the inside. Secure with instant glue.

Just be careful not to let the glue get into the button mechanism. Then solder the front ends of the wire to the motor contacts. We attach the end plate to the engine with glue.

We coat the ends of the pipe with glue and insert the motor with the plate into the pipe until the end plate rests on the ends of the pipe coated with glue. Press firmly for 10-15 seconds until the glue sets

We attach the rear end in the same way, not forgetting to first glue the plug connector to it with the ends of the wire soldered to it.

The main work is finished.

Now, using a file and sandpaper, we level the corners of the ends so that they are flush with the walls of the body.

Next, we install the plug from our connector on the power supply wire.

Don't forget about polarity.If you mix it up, nothing bad will happen, in principle, the shaft will simply spin in the wrong direction and, naturally, we will not be able to drill anything. However, if you plan to use this device only for cutting small objects or sharpening knives, then the polarity does not play a special role. All that remains is to install the collet cartridge on the shaft, and you can use it. I ordered a collet chuck, diamond pens for the drill machine, and thin drills from an online store.

Unfortunately, only the cartridge has arrived so far, so I was only able to demonstrate in the video the cutting and sharpening properties of the assembled device. And then, with homemade saw attachments. It sharpens metal, grinds, and cuts plastic quite quickly, which means it will be good for drilling.

Watch the video

Similar master classes

Particularly interesting