Homemade device for dismantling SMD without a hair dryer

Surface-mount electronic components, unlike traditional radio components, do not have flexible leads. Passive elements are made in the form of a cylinder or parallelepiped with metallized ends. In microcircuits with many pins, the electrodes are short and rigid and cannot be bent.

To remove a soldered SMD part from the board, it will not be possible to heat it with a soldering iron and separate each pin in turn in order to bend it from the contact pad. Therefore, the soldering area is blown with hot air from a hair dryer, heating all leads simultaneously until the solder melts and the part is released. If it turns out that you don’t have a hairdryer with you at the right time, you can, as a temporary measure, use a homemade attachment installed on the tip of any soldering iron.

Materials and tools

The device is made with conventional tools. You will need:

- soldering iron;

- pliers;

- wire cutters;

- tweezers.

The materials used are often used in common practice and are not difficult to obtain:

- Copper wire without insulation, diameter 1÷2 mm.If you have a choice, it is better to take a stiffer one so that it retains its bending shape.

- Thermal paste placed on the tip before winding promotes heat transfer.

- Liquid or gel-like inactive flux applied to the contacts before desoldering will improve uniformity of heating and heat distribution. Will dissolve the formed oxide.

- Lead-tin solder wire. It will help distribute the heat, making it uniform, between a large number of terminals.

Making the nozzle

Apply a little thermal paste to the tip of the tip, carefully distributing it evenly over the area where the coils of the nozzle will be laid. The thickness of the layer is approximately equal to half the diameter of the wire used.

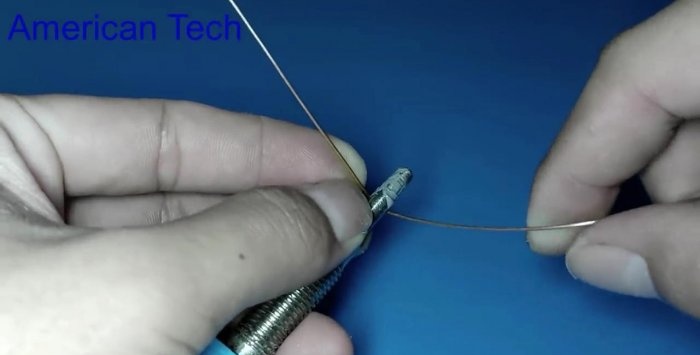

Take the copper wire and place it across the tip at the point where the winding begins.

Make 2-3 turns with the near end of the wire, embedding them with thermal paste and laying them tightly towards the end of the tip.

Lay the far end of the wire across the initial winding, then continue laying the turns with the near end, tightly clamping the wire to the tip.

After making another 5-6 turns, twist the near and far ends of the wire tightly together several times. Dense winding will securely secure the nozzle to the tip. All turns must be immersed in paste.

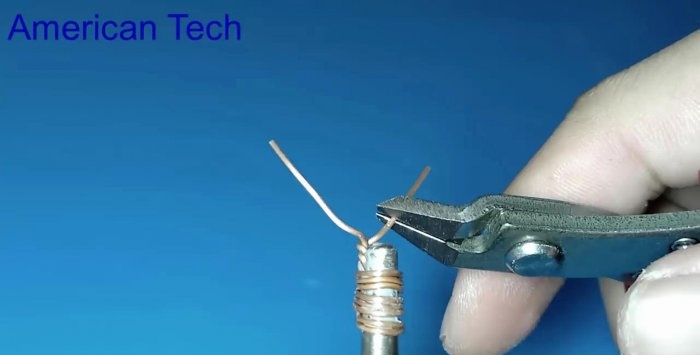

Using wire cutters, cut the ends of the resulting slingshot, leaving a length of 5 mm from the fork.

Using pliers, give the ends a fork shape with a distance equal to the length of the element between the metallized areas.

Dismantling resistors, capacitors, diodes

Using a stick, apply a small amount of flux to the contact pads.

Touch the contact pads of the part with the copper ends of the nozzle bent to the required distance.

The flux boils with a slight release of smoke, the solder melts, freeing the leads.

Use tweezers to remove the sealed part from the board.

We also solder all other components of the appropriate dimensions.

Soldering chips

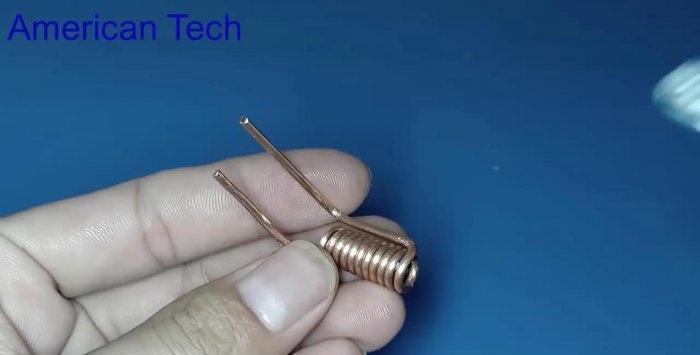

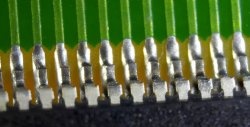

Elements with a large number of pins are soldered with a nozzle made according to the same principle, but the horns are cut according to the distance between the outermost pins in the row. The size and shape of the plug depends on the specific chip.

The 8-pin microcircuit is soldered with a plug of its own type.

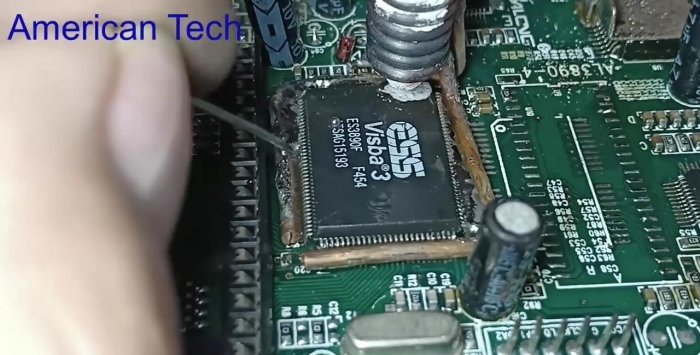

Filling the space between the terminals with molten solder wire will ensure uniform heat distribution and equal heating of all contacts.

The microcircuit can be freely removed from the board after the solder has melted.

Melted excess solder is removed from the pads.

By changing the size of the plug, a microcircuit with 16 pins is soldered. The procedure is as described.

The dismantling of a housing with 42 legs is similar.

To make the device, we take thicker wires for further heat distribution.

And we solder it using the same technology.

The terminals of the circuit in a square case with 26 contacts on each side are lubricated with flux.

Instead of a fork shape, wire tendrils of the required length are bent to form a square frame and the procedure is repeated.

Replacing thermal paste

Thermally conductive paste operates at temperatures up to 250 degrees Celsius. When it overheats, it dries, loses its properties and does not transfer heat from the tip to the nozzle. After soldering 2÷3 parts, the plug does not heat well.

- If you need to continue dismantling, remove the used nozzle.

- Wipe the sting from the dried paste, apply a fresh portion.

- Put a new attachment on the sting, which can be made in advance.

Recommendations for use

As a liquid flux, it is convenient to use a homemade solution of one part of pine rosin crushed into dust in three parts of medical alcohol.

Rapid burnout of the flux with heavy smoke indicates that the soldering iron is heating up too much.

You need to remember the rules for working with a hot soldering iron in order to avoid electrical injuries or burns and ensure the room is ventilated.

Watch the video

Similar master classes

Particularly interesting

Cable antenna for digital TV in 5 minutes

A selection of simple and effective schemes.

Three-phase voltage from single-phase in 5 minutes

Starting a three-phase motor from a single-phase network without a capacitor

Eternal flashlight without batteries

How to make an inexpensive but very powerful LED lamp

Comments (13)