Quick desoldering of SMD components using an iron

SMD parts are increasingly used in production, as well as among radio amateurs. It is more convenient to work with them, since there is no need to drill holes for leads, and the devices turn out to be very miniature.

SMD components can be completely reused. Here again the obvious superiority of surface mounting appears, because it is much easier to solder small parts. They are very easy to blow off from the board with a special soldering hair dryer. But if you don’t have one at hand, then an ordinary household iron will help you out.

Dismantling SMD parts

So my LED bulb is burned out and I won't fix it. I will solder it into parts for my future homemade products.

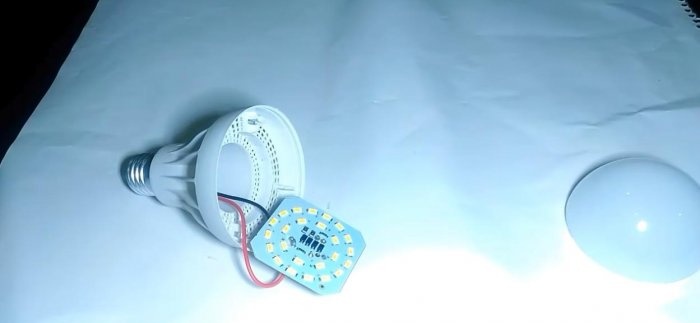

We disassemble the light bulb and remove the top cap.

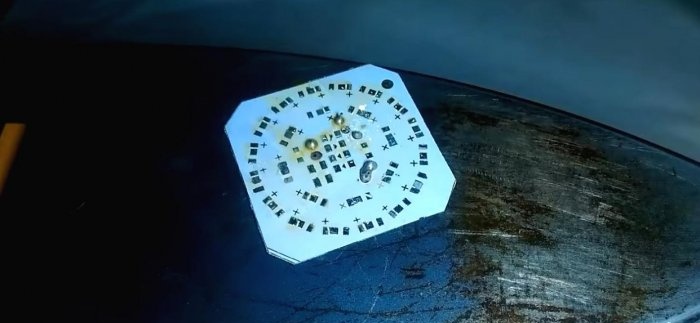

We take out the board from the base of the base.

We unsolder the attached components and parts, wires. In general, there should be a board with only SMD parts.

We fix the iron upside down. This must be done firmly so that it does not tip over during the soldering process.

Another good thing about using an iron is that it has a regulator that will quite accurately maintain the set temperature of the sole surface.This is a huge plus, since surface components are very afraid of overheating.

We set the temperature to about 180 degrees Celsius. This is the second mode for ironing clothes, if my memory serves me correctly. If soldering does not work, gradually increase the temperature.

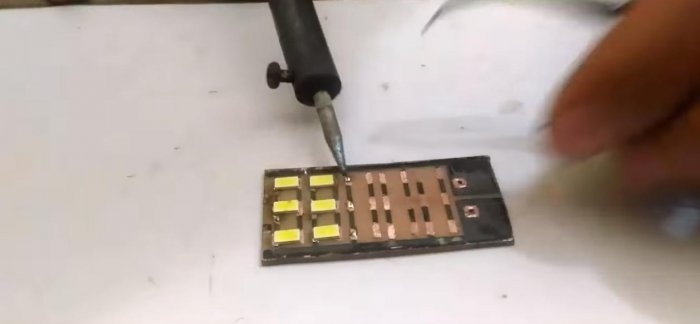

Place the light bulb board on the sole of the inverted iron.

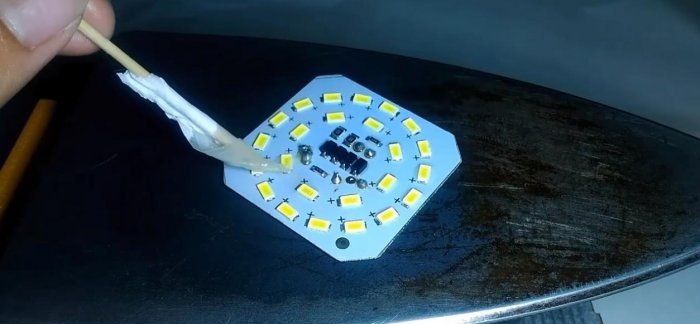

We wait 15-20 seconds until the board warms up. At this time, we wet every part with flux. The flux will not cause overheating, it will be a kind of assistant during desoldering. With it, all elements can be removed without difficulty.

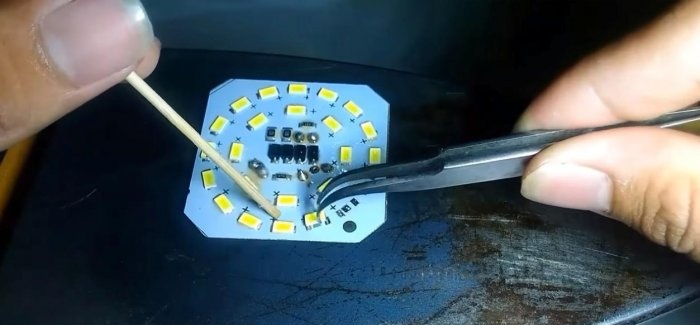

Once everything has warmed up well, all the parts can be brushed off the board by hitting the board on some surface. But I will do everything carefully. To do this, we will take a wooden stick to hold the board in place and use tweezers to disconnect each component of the board.

Bare board at the end of work:

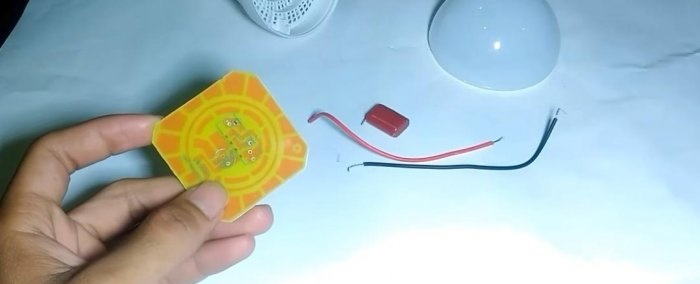

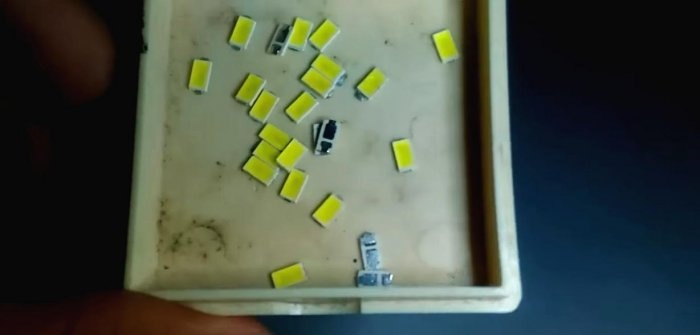

Soldered parts:

Everything is working, nothing burned.

What can be made from them? Of course it's up to you to decide!

I'll make a flashlight with a Krona battery.

This method will allow you to very quickly solder any boards with SMD parts. Take it into your arms, friends!

Watch the video on desoldering SMD parts

Similar master classes

Particularly interesting

Cable antenna for digital TV in 5 minutes

A selection of simple and effective schemes.

Three-phase voltage from single-phase in 5 minutes

Starting a three-phase motor from a single-phase network without a capacitor

Eternal flashlight without batteries

How to make an inexpensive but very powerful LED lamp

Comments (2)