How to Make a Three-Piece Corner Joint

For work, you can take pipes of any cross-section: round, square, but we will focus on rectangular products. The main principle will be the same everywhere: for precise joining of the connection elements, their ends are cut at 45 degrees each time.

Such a connection is usually used for aesthetic purposes, since for conventional structures there are simpler fastening options, but at the same time providing better strength characteristics.

In order not to be distracted while working, you should prepare the following tools and materials in advance:

This work can be divided into two parts: marking and, in fact, connecting. If the first part of the work is completed correctly and with the required accuracy, then the second turns into a simple formality.

So, let's begin:

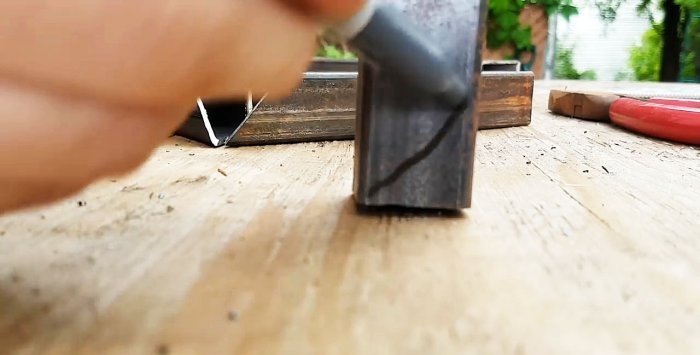

1.Using a triangle, we draw a line at 45 degrees on three segments along the wide side closer to one of the ends. To save material, it can be done at the very end - from one of the end corners.

2. We set the table of the pendulum saw on the scale at 45 degrees, which automatically ensures that the plane of the cutting tool disk is positioned in relation to the part being cut at the same angle.

3. We alternately make cuts according to the markings, which is duplicated for reliability by securing sections of rectangular pipes to the table using a removable clamp.

4. Rotate the pipes with beveled edges 90 degrees and again mark the markings at 45 degrees.

5. We repeat operation No. 3 again (installation, fastening, cutting), but according to the new markings.

6. We connect two prepared sections of pipes on a horizontal surface with their ends, along the larger diagonal of the cut. For reliability, you can measure the outer angle: it should be exactly 90 degrees.

7. We take the third section of the pipe and, having tried it on the first two in the assembly, we make the usual markings and use a pendulum saw to form a shaped part that will coincide with the corresponding edges of the first two sections assembled together.

Cut from both sides.

As a result, the corner connection is obtained by itself.

The second part of the work is the connection, which can be done by gluing if the material is wood or plastic, by soldering, gas-acetylene or electric welding if the parts are metal.

Such a connection is usually used for aesthetic purposes, since for conventional structures there are simpler fastening options, but at the same time providing better strength characteristics.

Will need

In order not to be distracted while working, you should prepare the following tools and materials in advance:

- three sections of rectangular pipe identical in cross-section and length;

- metal marking triangle with base angles of 45 degrees;

- marker;

- pendulum saw with rotary table;

- removable clamp.

Process for making a double corner joint

This work can be divided into two parts: marking and, in fact, connecting. If the first part of the work is completed correctly and with the required accuracy, then the second turns into a simple formality.

So, let's begin:

1.Using a triangle, we draw a line at 45 degrees on three segments along the wide side closer to one of the ends. To save material, it can be done at the very end - from one of the end corners.

2. We set the table of the pendulum saw on the scale at 45 degrees, which automatically ensures that the plane of the cutting tool disk is positioned in relation to the part being cut at the same angle.

3. We alternately make cuts according to the markings, which is duplicated for reliability by securing sections of rectangular pipes to the table using a removable clamp.

4. Rotate the pipes with beveled edges 90 degrees and again mark the markings at 45 degrees.

5. We repeat operation No. 3 again (installation, fastening, cutting), but according to the new markings.

6. We connect two prepared sections of pipes on a horizontal surface with their ends, along the larger diagonal of the cut. For reliability, you can measure the outer angle: it should be exactly 90 degrees.

7. We take the third section of the pipe and, having tried it on the first two in the assembly, we make the usual markings and use a pendulum saw to form a shaped part that will coincide with the corresponding edges of the first two sections assembled together.

Cut from both sides.

As a result, the corner connection is obtained by itself.

Conclusion

The second part of the work is the connection, which can be done by gluing if the material is wood or plastic, by soldering, gas-acetylene or electric welding if the parts are metal.

Watch the video

Similar master classes

Particularly interesting

Comments (4)