How to make a log splitter "carrot" in the garage

Chopping firewood manually with an ax or cleaver takes a lot of physical strength, so folk craftsmen have created many designs of mechanized wood splitters with a working body in the form of a carrot - a cone with a slight slope, on which a deep oblique thread is applied.

Below we will consider the sequence of making a “carrot” in a garage on a homemade lathe. Moreover, an unusable steel shaft of suitable diameter and length can be used as a blank.

At the same time, three different types of turning work will be performed on it:

- drill and bore a blind hole from one end to the required size to install a “carrot” on the drive shaft of a mechanized wood splitter;

- at the other end of the workpiece, grind a cone of a certain length and base diameter;

- cut a deep oblique thread over the entire surface of the cone.

Making split carrots on a lathe

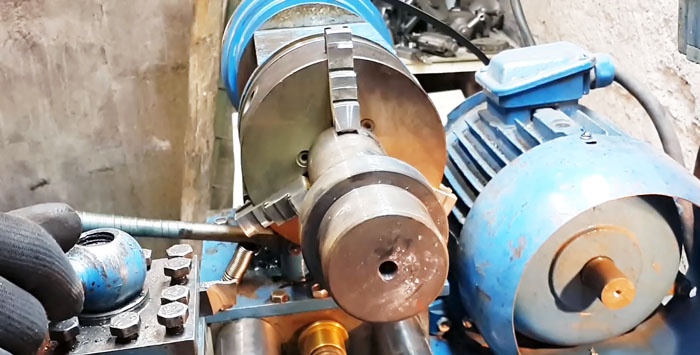

From theory to practice.The first operation begins with drilling a blind hole to the required depth with a drill whose diameter allows the turning tool to freely enter to the bottom of the blind hole.

Using a turning cutter, the hole obtained after drilling is bored to the required size, periodically checking its diameter with a caliper, and its taper along the length with a bore gauge. If necessary, some areas of the hole can be sanded using sandpaper wrapped around a round wooden rod.

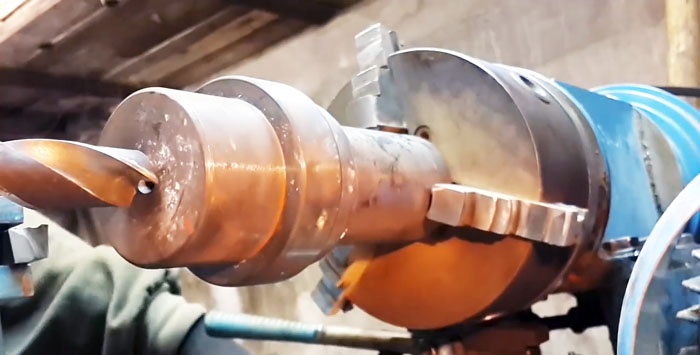

Then the workpiece is rearranged in the chuck with the other side and an outer cone is made with the specified parameters for the length and diameter of the base. This operation on a homemade lathe is quite difficult to perform, since the cutter is fed manually, which requires certain skills and dexterity.

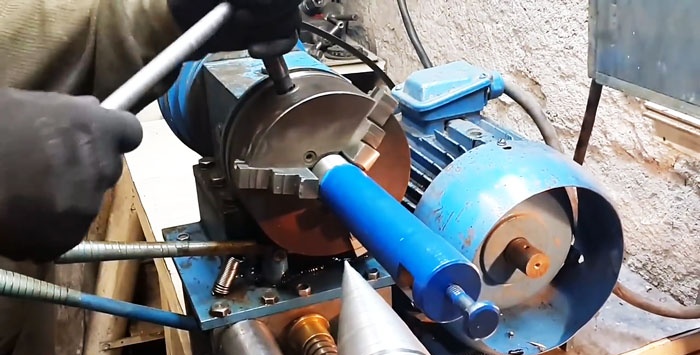

The third operation, cutting deep threads on the surface of the cone, will require some modernization of the lathe. In the tool holder, the cutter is replaced by a chuck, which is needed to hold the conical workpiece during its further processing.

Instead of a “carrot”, a holder is installed in the main chuck of the machine, in which a cutter for cutting threads on the surface of the cone is radially fixed using a bolt screwed into the end.

The complexity of this operation is due to the fact that the conical workpiece has to be adjusted in the transverse direction relative to the thread-cutting tool and at the same time rotated manually. The required thread cutting depth is achieved in several passes.

Result

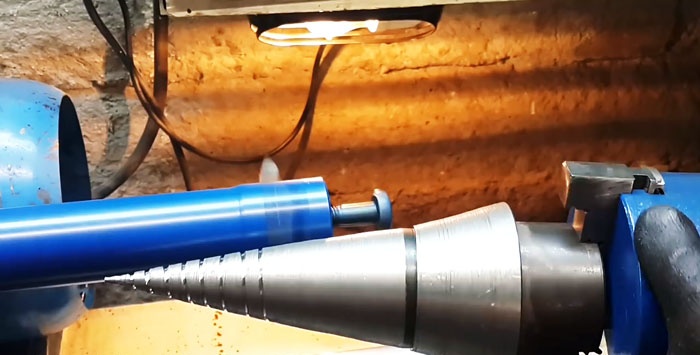

The finished wood splitter head is ready.

Watch the video

Similar master classes

Particularly interesting

Comments (1)