How to turn a bolt into a nice little souvenir hunting knife

Hunting knives are not always made for a utilitarian purpose. Sometimes it's just a souvenir or present, attracting attention, first of all, with the harmony of forms and quality of finishing.

Let's together turn a stainless steel bolt into a compact masterpiece that, while pleasing to the eye, will be very durable, sharp and even ready for use for its intended purpose.

The order of work is quite definite. Select a suitable size stainless steel bolt.

We clamp it in a vice and cut off the bolt head with a grinder with a cutting disc.

We slightly trim the area under the head with a grinding wheel.

Holding the bolt by the threads with pliers, heat the bolt from the other edge until red hot with the fire of a gas burner.

Then, using a hammer on the anvil of a vice, we form the blade of the knife. We repeat heating and forging until the original shape and dimensions of the blade are achieved.

To avoid mistakes, we apply the partially processed workpiece to the drawing of a knife of natural dimensions.The projection of the metal workpiece must overlap the pattern in all sections.

After this, we clamp the workpiece in a vice and process it with a grinding disc, removing forging defects and removing excess metal from both sides.

Carefully cut out the knife design from paper with a scalpel, place it on the workpiece and trace it in all the details with a marker.

We again clamp the workpieces in a vice and use a grinder with a roughing and cutting disk to roughly form the profile of the knife according to the applied projection.

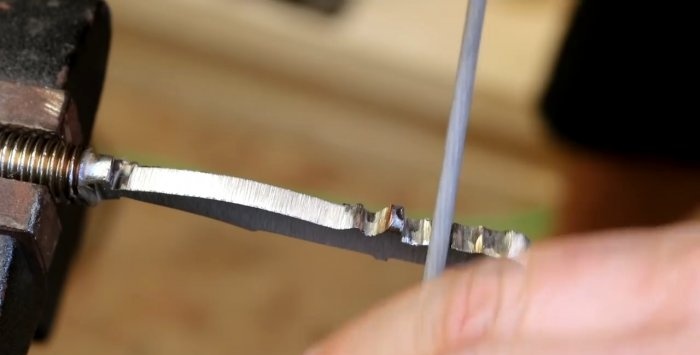

Next, we continue processing with a round file, and most of all this applies to the transverse profile of the knife handle.

We process the side profile of the handle with a Dremel with a small cutting disc.

We remove excess metal from both sides of the workpiece using a grinder.

We smooth out the sharp edges on the workpiece with a round file, and form the profile with a small cutter attached to the spindle of a mini-drill.

Grinding and final polishing of the knife is done manually using sandpaper of decreasing grit.

Using a jigsaw, we cut out the linings for the knife handle from an oil-soaked wooden block.

We bring them to the desired shape and size on the grinder, while simultaneously correcting parts of the blade.

Prepare two-component glue. Glue the pads to the handle on both sides. To secure the connection, we compress them for a while in a bench vice, placing wooden protective bars on the jaws.

After making sure that the linings are firmly attached to the handle, we perform their final processing with a hand file.

We drill two through holes in the pads and handle using a drill with a suitable drill bit.

We insert the pins, which should fit tightly into the holes and stay there firmly. We cut off their protruding parts on both sides with a Dremel or grinder.

We clean the ends of the pins on a grinder and form the blade of the blade, pressing it against an endless sanding belt with a wine stopper to ensure uniform and not hard pressure.

The final finishing of the handle with overlays is carried out using mechanical emery with a polishing disc, having previously processed a wooden blank on it.

All that remains is to sharpen the blade of the blade sequentially on three whetstones of decreasing grain size, and placed in a bath of water.

The sharpness of the blade is such that it easily cuts off delicate and thin hairs on the back of the hand.

To preserve sharpening and reduce the impact of adverse factors, as well as for safe wearing or storage, a case will not hurt. You can sew it from a piece of genuine leather.

Our work was not in vain: the knife turned out to be beautiful in profile, proportional in size and very sharp.

Let's together turn a stainless steel bolt into a compact masterpiece that, while pleasing to the eye, will be very durable, sharp and even ready for use for its intended purpose.

Manufacturing process

The order of work is quite definite. Select a suitable size stainless steel bolt.

We clamp it in a vice and cut off the bolt head with a grinder with a cutting disc.

We slightly trim the area under the head with a grinding wheel.

Holding the bolt by the threads with pliers, heat the bolt from the other edge until red hot with the fire of a gas burner.

Then, using a hammer on the anvil of a vice, we form the blade of the knife. We repeat heating and forging until the original shape and dimensions of the blade are achieved.

To avoid mistakes, we apply the partially processed workpiece to the drawing of a knife of natural dimensions.The projection of the metal workpiece must overlap the pattern in all sections.

After this, we clamp the workpiece in a vice and process it with a grinding disc, removing forging defects and removing excess metal from both sides.

Carefully cut out the knife design from paper with a scalpel, place it on the workpiece and trace it in all the details with a marker.

We again clamp the workpieces in a vice and use a grinder with a roughing and cutting disk to roughly form the profile of the knife according to the applied projection.

Next, we continue processing with a round file, and most of all this applies to the transverse profile of the knife handle.

We process the side profile of the handle with a Dremel with a small cutting disc.

We remove excess metal from both sides of the workpiece using a grinder.

We smooth out the sharp edges on the workpiece with a round file, and form the profile with a small cutter attached to the spindle of a mini-drill.

Grinding and final polishing of the knife is done manually using sandpaper of decreasing grit.

Using a jigsaw, we cut out the linings for the knife handle from an oil-soaked wooden block.

We bring them to the desired shape and size on the grinder, while simultaneously correcting parts of the blade.

Prepare two-component glue. Glue the pads to the handle on both sides. To secure the connection, we compress them for a while in a bench vice, placing wooden protective bars on the jaws.

After making sure that the linings are firmly attached to the handle, we perform their final processing with a hand file.

We drill two through holes in the pads and handle using a drill with a suitable drill bit.

We insert the pins, which should fit tightly into the holes and stay there firmly. We cut off their protruding parts on both sides with a Dremel or grinder.

We clean the ends of the pins on a grinder and form the blade of the blade, pressing it against an endless sanding belt with a wine stopper to ensure uniform and not hard pressure.

The final finishing of the handle with overlays is carried out using mechanical emery with a polishing disc, having previously processed a wooden blank on it.

All that remains is to sharpen the blade of the blade sequentially on three whetstones of decreasing grain size, and placed in a bath of water.

The sharpness of the blade is such that it easily cuts off delicate and thin hairs on the back of the hand.

To preserve sharpening and reduce the impact of adverse factors, as well as for safe wearing or storage, a case will not hurt. You can sew it from a piece of genuine leather.

Bottom line

Our work was not in vain: the knife turned out to be beautiful in profile, proportional in size and very sharp.

Watch the video

Similar master classes

Particularly interesting

Comments (1)