How to easily and cost-effectively “make” a chainsaw cut smoothly

Many, even new chainsaws, cut crookedly. Is it possible to eliminate this deficiency on your own and what needs to be done to do this? Most often this problem is related to the chain, bar or sprocket. But before you take on them, it won’t hurt to replenish your knowledge about the operation of a chainsaw.

Theory first

Without knowing the following theoretical principles, it is difficult to determine the factors why the tool cuts crookedly and how to deal with them.

The first reason is due to the fact that the chain teeth wear unevenly due to the fact that, for example, nails get under them.

Therefore, the saw’s cutting qualities deteriorate and, in order to compensate for them, we begin to put more pressure on the bar.

How does the saw react to this? With its sharp teeth, it continues to easily deal with wood, and dull teeth do not cut wood, but roll over like a car wheel over a pothole. But the wheel is helped by a shock absorber, while the saw does not have one.

As a result, the chain moves in the groove and rapid wear of one or another edge occurs. The chain shanks and the groove along which they move also wear unevenly.

The movement of the chain along the bar becomes uneven. If you do not pay attention to this situation, the wear process will only increase.

The second reason for accelerated wear is associated with incorrect or untimely tensioning of the chain, which is the most loaded among the chainsaw components. It is recommended to tighten it to such an extent that when lifted with your fingers, the lower part of the three shanks is visible. But this method of determining tension is not entirely accurate.

The chain is tensioned when the saw is cold. If this is done correctly, then no sagging is visible and the chain moves easily along the bar. This also has its own subtleties. When the saw is running, the chain first heats up and its natural sagging is observed, since the metal expands when heated. If you do not take this into account and tighten the chain, you can worsen the situation. When the saw is turned off, the chain cools down and tightens.

With further sawing, the tire warms up and increases in size with some delay, which also causes the chain to tighten. And this leads to additional loading of the bearings, sprocket, tire and rapid stretching of the chain.

If the chainsaw is hot, it is easy to lengthen, along with an overtightened, unsharpened chain, which together contributes more to the wear of the bar and chain. The picture will remain unchanged if you install a chain in oil on a worn tire. Sawing with such a chainsaw will remain crooked.

Now practice eliminating crooked sawing

How to get rid of this defect? The first thing that needs to be done is to sharpen the chain using a stationary machine, and rearrange the bar to the other side.

If this has been done before, and the tire shows uneven wear on both sides, then it will have to be straightened. To do this you should get:

- square;

- bench vice;

- grinder;

- new grinding wheel.

A test cut shows that the saw still pulls to the side.

Let's remove and work on the tire. Let's place it on a flat surface and attach a square. If there is a gap between them, then there is wear.

To fix it, clamp the grinder with the sharpening disc in a vice.

From the outside, at the level of the disk, we make a rigidly motionless plane.

Next, we align the disc with the square and secure the grinder.

Now we place the tire on a horizontal plane and, after turning on the grinder, grind the ribs on both sides. We check the groove with a square and make sure that it is made with high quality.

Next, we check that the chain shanks have enough height of the bar groove. If this is not the case, then the tire must be replaced with a new one.

We assemble the saw, tension the chain and check the cutting quality. Sawing should be efficient and the saw should not move to the side.

Attention - chain!

It’s worth remembering that you can’t cut with a weakened chain. After all, if a chip or branch gets into the gap, the consequences can be unpredictable. When the saw does not have a chain catcher and the bar is extended, the chain can cause serious injury to the legs when it wraps around them.

When the chain jumps off the tire, the main impact energy is absorbed by the chain catcher. But at the same time, the star also suffers greatly.

If this happens several times, the sprocket becomes deeply grooved and chain tension becomes a problem. When it gets into a groove, it weakens, and when it comes out of it, it gets tension.

In this case, an urgent replacement of the sprocket is required so as not to lead to chain breakage, bearing scattering, or sprocket breakage.

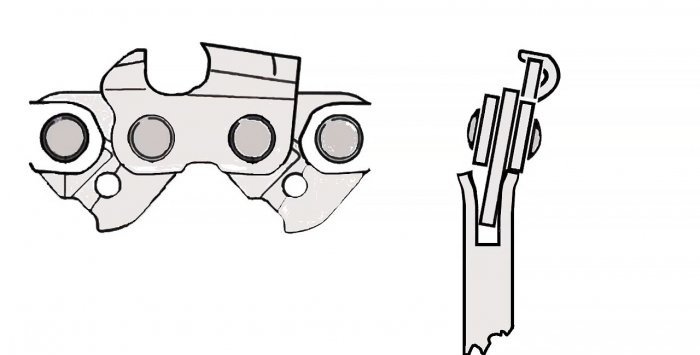

Even a new chain can break if the connecting strips are installed incorrectly at the riveting site. Chains arrive in coils, so their riveting and packaging is inevitable.

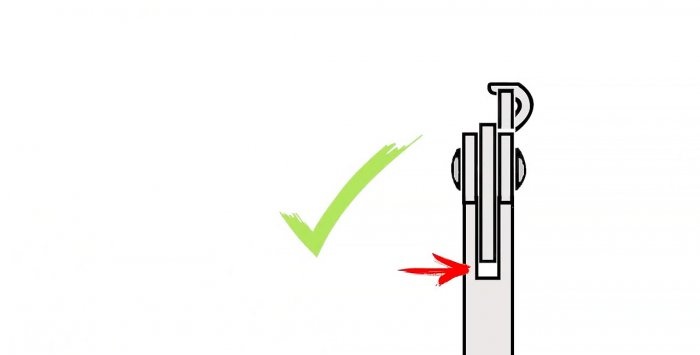

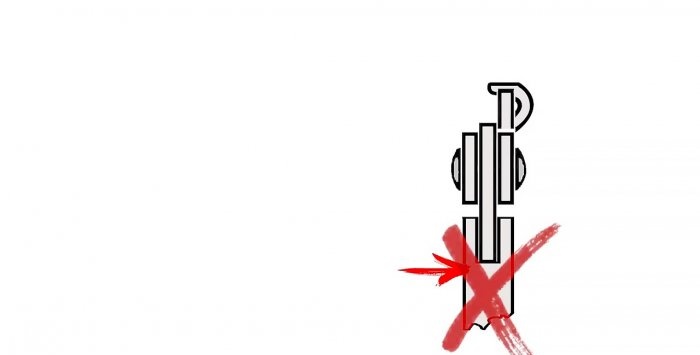

This means that when buying a chain, you need to pay a lot of attention to the connecting link. The rivets on them should be larger or lighter. You also need to check whether the connecting strips are installed correctly. Sometimes the direction is indicated by an embossed arrow. When the arrow is missing, correct installation is determined by the front support, which is slightly larger than the rear.

If the connecting bar is installed incorrectly, it will go awry. The connecting link will have to take an increased load, which will cause the rivet to shear, which will lead to the chain breaking.

Constant care of the sprocket, bar and chain will certainly increase the life of the chainsaw.