Molding plastic parts at home. As easy as pie

The manufacture of casting products using modern materials has become quite accessible, quite simple and low-cost. Consider the option of using polyurethane for pouring and silicone to create the mold.

Will need

For our work we will use quite accessible and inexpensive materials and products:

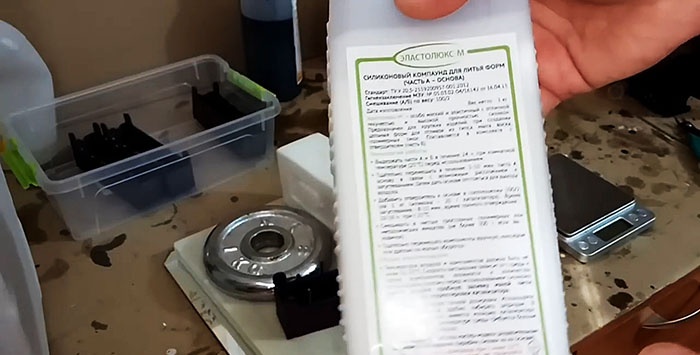

- silicone "ELASTOLUX-M" for making molds;

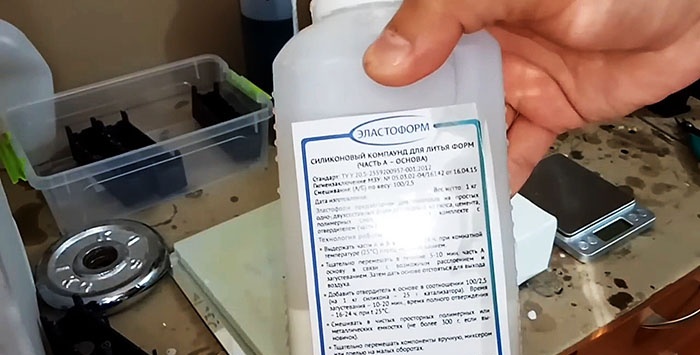

- silicone "ELASTOFORM" for the manufacture of the substrate;

- separator based on kerosene or petroleum jelly;

- bending for the mold with a total weight of 1 kg;

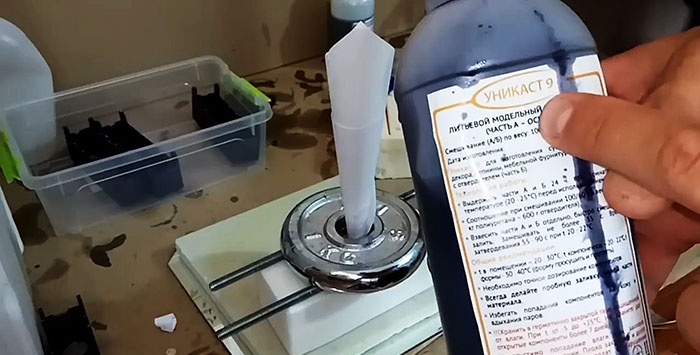

- casting polyurethane "UNIKAST 9" (base, part A);

- hardener (part B);

- precision scales;

- plastic glass.

Technology of casting polyurethane products into silicone molds

First of all, you need to print a master model with a gating system on a 3D printer. Or take a finished part that needs to be repeated, glue toothpicks into the role of sprues. It will be needed to make a reusable silicone mold.

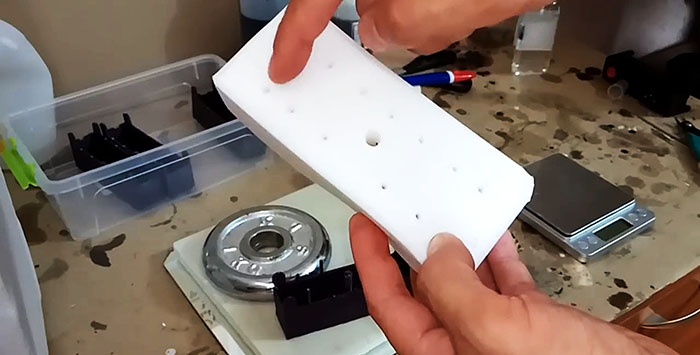

For it we use silicone, which is highly elastic and sufficiently durable.For a base substrate with a thickness of 10-15 mm, less expensive two-component silicone of the ELASTOFORM type is suitable.

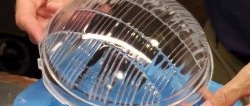

Made silicone mold.

How does the casting process work?

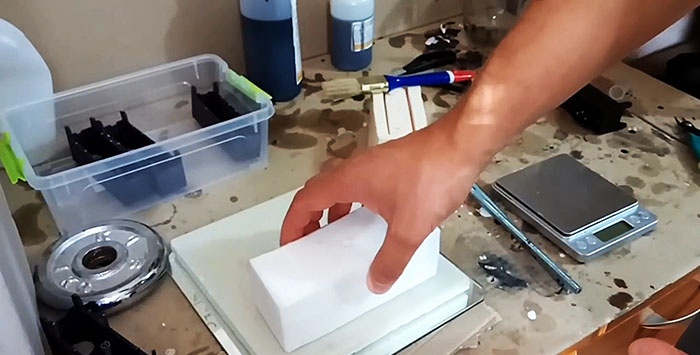

We place the silicone mold on the substrate. If it will be used repeatedly, then periodically lubricate it with a separator based on kerosene or petroleum jelly.

We press the silicone mold on top with a dispersed load (pressure) weighing up to one kilogram. To ensure that the casting material is poured accurately and quickly, we use a paper funnel. After which, we can assume that the mold is prepared for casting.

To fill, we take the cheapest casting polyurethane “UNIKAST 9” (part A) and hardener (part B), which we mix in a ratio of 1:0.6.

For high-quality mixing you need precision scales and a plastic cup. You can add any color dye to the base, which is sold separately. For 1 kg of polyurethane you need 90-100 drops of dye.

Pour 22 grams of liquid polyurethane and 13.2 grams of hardener into a glass on a scale and stir thoroughly for 30 seconds, no more, since it will already begin to harden. When stirring, we will feel that the glass is heating up, which means the polymerization process has begun. The mixture is ready to pour.

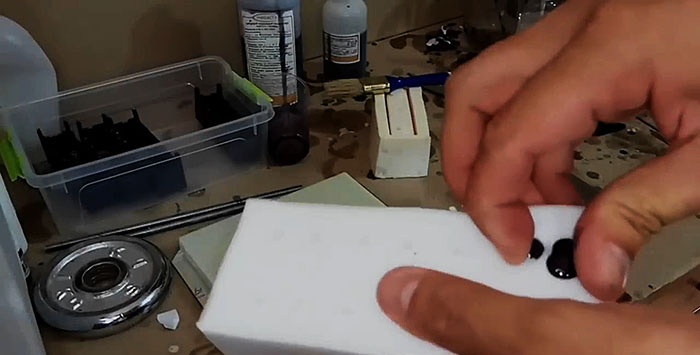

We pour the mixture without interruption until liquid polyurethane comes out of the sprues. Primary hardening will take about two minutes, and complete hardening will take 10-15 minutes, but it is better to keep the filling in the mold for 20-30 minutes.

After half an hour, we begin to remove the polyurethane casting from the silicone mold.

We first break off the paper funnel with excess polyurethane frozen in it, then the excess protruding from the sprues, along with the “legs”. This will make it easier for us to remove the cast product from the mold.

In addition, the silicone mold is highly flexible, which also makes it easy to remove the casting from it without any difficulty.

All that remains is to lightly process the holes, break off or cut off the sprues and drill the holes with a drill. After this, the cast product is practically no different from the master mold.

Comparison of casting method and 3D printing

Casting compared to 3D printing is a fast process. To print such a box on a 3D printer, it will take 4.0-4.5 hours. In this case, the 3D model often turns out to be defective and everything has to be started over. The casting process takes a maximum of 30 minutes. The next point is cheapness. Casting is more than 3 times cheaper than 3D printing.