How to make a snow blower from a plastic barrel

Removing snow by hand is not easy and takes a long time. Buying a mechanical cleaner is expensive because of its high cost. But you can make a snow blower on wheels that you just need to push, which is easier than swinging a shovel. And it will cost two orders of magnitude cheaper than a mechanical unit, which also needs fuel.

To make a homemade device that can be considered both as a pusher and as a blade, we should have the following materials and products available:

To work on our homemade product we will need: pendulum and jigsaw, drilling machine, welding, magnetic and measuring square.

Using a pendulum saw, we cut off one fragment of predetermined sizes from a thick and thinner steel strip.

From a fragment with a larger thickness, use a jigsaw to cut off corners of the given dimensions and inclination on one side.

In a thin fragment we drill four holes in the corners.

In the plate with cut corners, we drill five symmetrically located holes, which border the profile of the plate on the side without corners.

We weld another vertically along the center of the rectangular plate, pointing the side with the cut corners upward.

We insert a threaded rod into the square pipe so that its ends protrude from the pipe to the same length on both sides. After which, we weld these parts to each other.

We cut off a piece of the required length from the widest strip. Having stepped back the required distance from one end along the longitudinal central axis, we drill one hole and a second hole slightly higher.

We lay the cut strip with the side without holes at a right angle in the center of the square pipe with the rod and in this position weld them to each other.

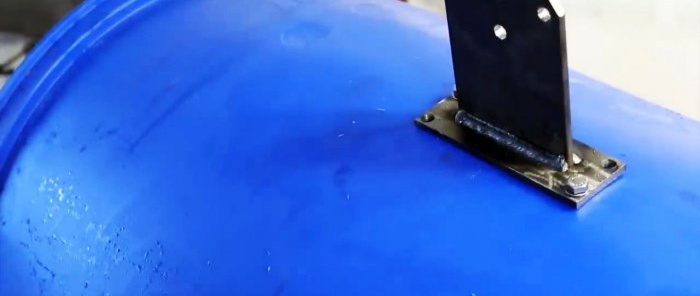

We cut the plastic barrel lengthwise into two halves with a jigsaw. To one of them, to the center from the outside, we apply the previously made fastening and rotating unit.

Using the holes in the plate, we mark and drill exactly the same ones in the plastic. With their help, we fasten these two parts together with bolts, screwing the nuts on the back side.

We cut off the end of a square pipe with a larger cross-section at a given angle. We place the cut end against the plate above the transverse pipe with the rod inside and weld it.

On two pieces of square pipe of a smaller cross-section, closer to one end, we make triangular cutouts with a jigsaw and bend them at 90 degrees. We weld the bends for strength.

We weld the L-shaped parts with the long part at the other end of the square pipe on both sides so that they are parallel to the threaded rod, and the short ones “look” down.

We put rubber wheels on the ends of the rod, which is also an axis, and secure them with nuts.

We place the end of the plate with the holes on the element of the fastening and rotating unit with six holes and secure it with a bolt, which will also serve as an axis for rotating the working element.

To do this, turn the handle and align the second hole with the desired hole on the fastening-rotary unit and secure it with a bolt and nut. Our snow blower on wheels is ready to go.

Removing snow like this is a pleasure.

Will need

To make a homemade device that can be considered both as a pusher and as a blade, we should have the following materials and products available:

- thick steel strip of different thickness and width;

- profile square pipe of different sections;

- threaded steel rod;

- plastic barrel;

- bolts and nuts;

- two rubber wheels with nuts.

To work on our homemade product we will need: pendulum and jigsaw, drilling machine, welding, magnetic and measuring square.

The process of making a snow blower from a barrel

Using a pendulum saw, we cut off one fragment of predetermined sizes from a thick and thinner steel strip.

From a fragment with a larger thickness, use a jigsaw to cut off corners of the given dimensions and inclination on one side.

In a thin fragment we drill four holes in the corners.

In the plate with cut corners, we drill five symmetrically located holes, which border the profile of the plate on the side without corners.

We weld another vertically along the center of the rectangular plate, pointing the side with the cut corners upward.

We insert a threaded rod into the square pipe so that its ends protrude from the pipe to the same length on both sides. After which, we weld these parts to each other.

We cut off a piece of the required length from the widest strip. Having stepped back the required distance from one end along the longitudinal central axis, we drill one hole and a second hole slightly higher.

We lay the cut strip with the side without holes at a right angle in the center of the square pipe with the rod and in this position weld them to each other.

We cut the plastic barrel lengthwise into two halves with a jigsaw. To one of them, to the center from the outside, we apply the previously made fastening and rotating unit.

Using the holes in the plate, we mark and drill exactly the same ones in the plastic. With their help, we fasten these two parts together with bolts, screwing the nuts on the back side.

We cut off the end of a square pipe with a larger cross-section at a given angle. We place the cut end against the plate above the transverse pipe with the rod inside and weld it.

On two pieces of square pipe of a smaller cross-section, closer to one end, we make triangular cutouts with a jigsaw and bend them at 90 degrees. We weld the bends for strength.

We weld the L-shaped parts with the long part at the other end of the square pipe on both sides so that they are parallel to the threaded rod, and the short ones “look” down.

We put rubber wheels on the ends of the rod, which is also an axis, and secure them with nuts.

We place the end of the plate with the holes on the element of the fastening and rotating unit with six holes and secure it with a bolt, which will also serve as an axis for rotating the working element.

To do this, turn the handle and align the second hole with the desired hole on the fastening-rotary unit and secure it with a bolt and nut. Our snow blower on wheels is ready to go.

Removing snow like this is a pleasure.

Watch the video

Similar master classes

How to make a device for removing snow from a roof

Do-it-yourself snow blower from a brush cutter

A lift for instantly jacking up a car with your own

How to turn a drill into a router using simple equipment

How to make a powerful vice from a diamond screw jack

Do-it-yourself mechanical thickness gauge couldn't be easier

Particularly interesting

Comments (2)