How to make roof tiles from plastic bottles

After one use, plastic bottles and kegs usually gather dust somewhere, take up a lot of space and eventually end up in a landfill. But this is an excellent material for making roofing slate or tiles for a gazebo, shed, shed, etc.

To realize your idea, you need to prepare the following materials, tools and equipment:

Since you will have to work with boiling water and heated plastic, it is advisable to wear a long-sleeved shirt, gloves and safety glasses.

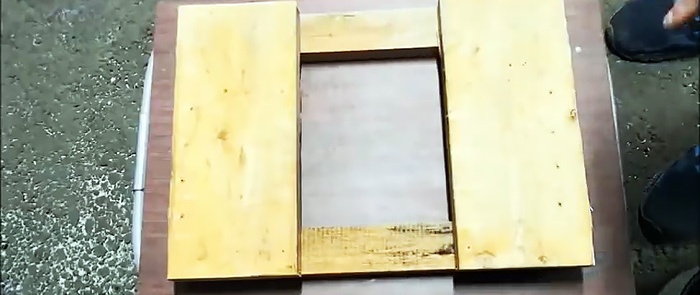

First, let's prepare a simple device for making slate or tiles from plastic bottles or kegs. To do this, we lay two identical pieces of board parallel to each other at a distance slightly less than the width of the plastic strip that remains after removing the neck and bottom parts of the keg.We fasten the sections of boards from the bottom along the edges with two transverse bars.

We cut the central part of the keg along the generatrix and get a plastic sheet. We lay it lengthwise on the inside of the boards and fasten one side with self-tapping screws with a large head using a drill.

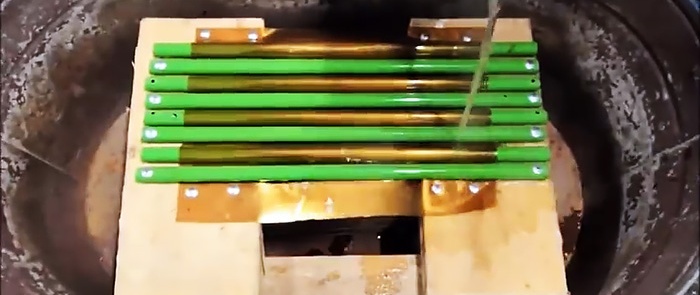

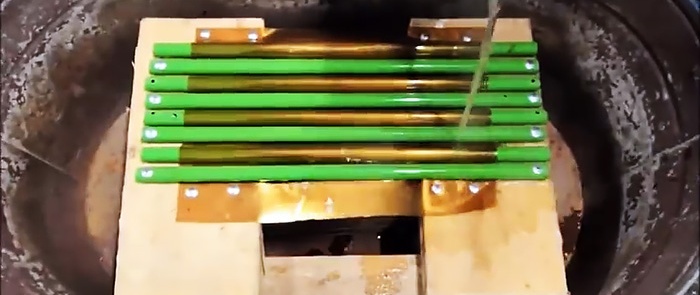

We lay metal rods with holes at the ends and a length slightly larger than the width of the strip, one on the bottom and the other on top of the plastic strip, pressing them tightly against each other. We attach all the upper rods to the boards using two self-tapping screws. Having received the required number of corrugations, we attach the end of the strip to the board, just like its beginning.

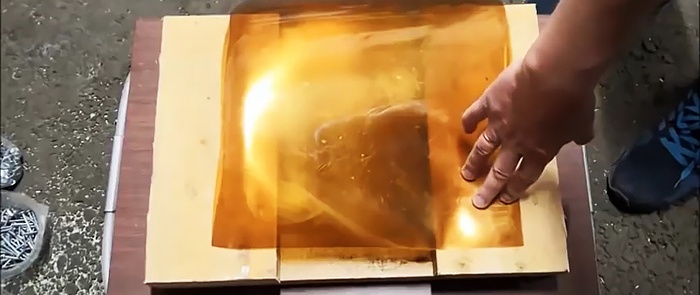

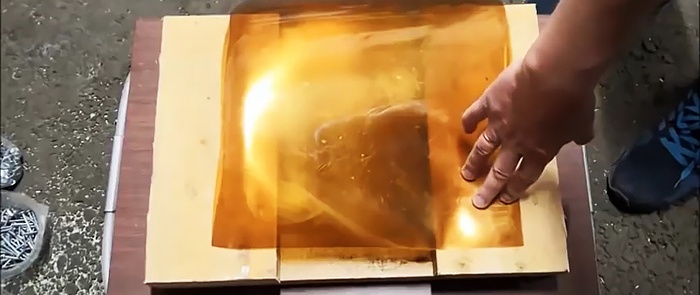

We begin to thermally shrink the film to obtain a corrugated relief, pouring it evenly over the entire area with some boiling water from a kettle or other suitable container.

We keep the film in this state until it cools completely. Then we unscrew the screws, remove the rods and release the ends of the film. Thanks to the formed corrugations, the material acquired longitudinal stability and rigidity, as well as transverse elasticity.

If desired, you can make a device that will ensure the production of corrugated sheets with a width of 31 cm and a length of more than 60 cm. It is also important to come up with a way to quickly install and remove the cross rods to form the corrugations.

Will need

To realize your idea, you need to prepare the following materials, tools and equipment:

- plastic beer bottles or kegs;

- two wooden blocks;

- two pieces of wooden boards;

- drill;

- self-tapping screws;

- metal rods;

- container with hot water.

Since you will have to work with boiling water and heated plastic, it is advisable to wear a long-sleeved shirt, gloves and safety glasses.

Roofing material manufacturing process

First, let's prepare a simple device for making slate or tiles from plastic bottles or kegs. To do this, we lay two identical pieces of board parallel to each other at a distance slightly less than the width of the plastic strip that remains after removing the neck and bottom parts of the keg.We fasten the sections of boards from the bottom along the edges with two transverse bars.

We cut the central part of the keg along the generatrix and get a plastic sheet. We lay it lengthwise on the inside of the boards and fasten one side with self-tapping screws with a large head using a drill.

We lay metal rods with holes at the ends and a length slightly larger than the width of the strip, one on the bottom and the other on top of the plastic strip, pressing them tightly against each other. We attach all the upper rods to the boards using two self-tapping screws. Having received the required number of corrugations, we attach the end of the strip to the board, just like its beginning.

We begin to thermally shrink the film to obtain a corrugated relief, pouring it evenly over the entire area with some boiling water from a kettle or other suitable container.

We keep the film in this state until it cools completely. Then we unscrew the screws, remove the rods and release the ends of the film. Thanks to the formed corrugations, the material acquired longitudinal stability and rigidity, as well as transverse elasticity.

If desired, you can make a device that will ensure the production of corrugated sheets with a width of 31 cm and a length of more than 60 cm. It is also important to come up with a way to quickly install and remove the cross rods to form the corrugations.

Watch the video

Similar master classes

Particularly interesting

Comments (2)