Now you can coat any steel with copper yourself

Copper plating is used to protect steel surfaces from corrosion and give them a decorative effect. There are several ways to make it at home, the simplest of which is to use copper sulfate and a solution of sulfuric acid.

100 grams must be dissolved in a glass container. copper sulfate in 150 ml. distilled water heated to +40°C.

The solution must be stirred until the vitriol crystals are completely dissolved.

Then 50 ml of alcohol is added to it and 250 ml of battery acid electrolyte is poured.

The components do not produce any visible chemical reaction when mixed, so no special precautions are required. The main thing is to avoid getting the electrolyte on the skin, since the sulfuric acid it contains in the current concentration causes an acute burning sensation.

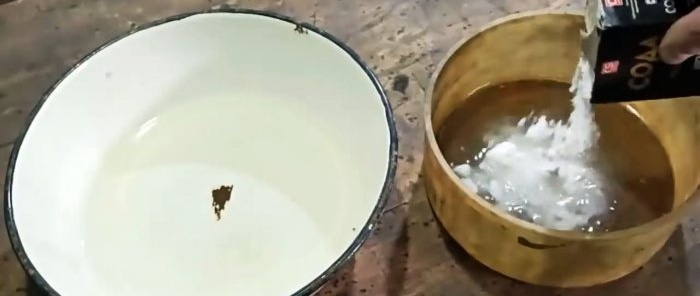

Solutions of alkali and soda are prepared in two separate containers. They use regular tap water.1 liter of water is poured into the container. Add 1-2 tbsp to one. spoons of baking soda, and secondly the same amount of alkali-based cleaner.

Prepared metal products are used for copper plating. They must be stripped to bare metal and preferably polished, since a layer of copper will not cover potholes and other defects. The prepared product must be degreased and cleaned of oxide by rinsing in alkali using a dish scraper.

Then the product is dipped into a vitriol solution. A few immersions are enough for the copper to be released from the solution and deposited on the steel surface. Next, the part is removed and dipped in a soda solution to extinguish the acid.

Then it needs to be washed with a scraper in alkali.

After this, the product is again immersed in vitriol. 2-3 repetitions are enough for the entire surface to be covered with copper without gaps.

This method can protect steel tools from corrosion.

They can also be used to decorate forged items, candlesticks and other interior items made of ferrous metals. Over time, they will become covered with a patina, which will only increase their decorative value. If greening is undesirable, then the copper must be opened with a colorless varnish. The method is very simple and fast, and most importantly inexpensive. All reagents for it can be bought in regular stores, so everyone can repeat it at home.

Materials:

- copper sulfate;

- alcohol;

- battery electrolyte;

- distilled water;

- baking soda;

- alkaline detergent powder;

- scraper for washing dishes.

Copper plating process

100 grams must be dissolved in a glass container. copper sulfate in 150 ml. distilled water heated to +40°C.

The solution must be stirred until the vitriol crystals are completely dissolved.

Then 50 ml of alcohol is added to it and 250 ml of battery acid electrolyte is poured.

The components do not produce any visible chemical reaction when mixed, so no special precautions are required. The main thing is to avoid getting the electrolyte on the skin, since the sulfuric acid it contains in the current concentration causes an acute burning sensation.

Solutions of alkali and soda are prepared in two separate containers. They use regular tap water.1 liter of water is poured into the container. Add 1-2 tbsp to one. spoons of baking soda, and secondly the same amount of alkali-based cleaner.

Prepared metal products are used for copper plating. They must be stripped to bare metal and preferably polished, since a layer of copper will not cover potholes and other defects. The prepared product must be degreased and cleaned of oxide by rinsing in alkali using a dish scraper.

Then the product is dipped into a vitriol solution. A few immersions are enough for the copper to be released from the solution and deposited on the steel surface. Next, the part is removed and dipped in a soda solution to extinguish the acid.

Then it needs to be washed with a scraper in alkali.

After this, the product is again immersed in vitriol. 2-3 repetitions are enough for the entire surface to be covered with copper without gaps.

This method can protect steel tools from corrosion.

They can also be used to decorate forged items, candlesticks and other interior items made of ferrous metals. Over time, they will become covered with a patina, which will only increase their decorative value. If greening is undesirable, then the copper must be opened with a colorless varnish. The method is very simple and fast, and most importantly inexpensive. All reagents for it can be bought in regular stores, so everyone can repeat it at home.

Watch the video

Similar master classes

Particularly interesting

Comments (4)