How to make a “leather” sheath from ordinary fabric

Sheaths for knives, cases for phones and other equipment can be glued together from denim fabric with special impregnation. After processing, it becomes similar to leather, but is superior in wear resistance. The impregnated fabric retains its shape longer, does not wear out and is pleasant to the touch. Having made such material, you can easily glue anything from it without using threads.

Cotton or denim should be used as a blank for the sheath. You can simply cut a piece from old jeans. Then it needs to be soaked. The impregnation composition includes PVA glue and deep penetration primer for impregnation of walls in a 50:50 ratio.

Also, the required amount of ink of the desired color or color scheme for paints is added to the mixture.

The fabric is brushed and dried.

For the second impregnation, a little chromium is added to the composition to increase its water resistance. This component can be purchased inexpensively at a chemical store.

The piece of fabric is soaked and dried after each layer until it becomes as tough as leather.

To speed up the process, the layers can be dried with a hair dryer.

Next, a knife blade is applied to the edge of the fabric. It is cut along its contour. Then an indent of 4-5 mm is made from the cut edge, and the material is bent along the spine of the blade. It is then cut along the previously trimmed edge.

To increase rigidity, the cut out workpiece is coated from the inside with a mixture of PVA with a pinch of chromium. This is a thick mass, so it is difficult to spread it with a brush. To do this, use a spatula or plastic card.

After the glue has dried, you need to take a little PVA mixture from the chromium pins into a syringe, and apply it along the edge of the workpiece to glue the layers. It is important that there is a small gap between the blade and the glue seam. The composition will set in half an hour.

Next, you need to trim the nose part of the sheath from the side of the butt, where the blade does not reach. The cut is made slightly short of the knife. Then PVA with chrome peak is applied on it from the inside.

From the side where the blade enters, the sheath needs to be trimmed by 3-4 mm along the sides and a fold should be made. Then the outer surface of the sheath and the remaining unused piece of fabric are coated with a strengthening compound, but only on one side.

After the composition has dried, it is applied again to glue the second layer of fabric to the sheath. You also need to glue the hem at the entrance of the sheath. After drying the glue with a hairdryer, you can trim it. Excess fabric on the nose is also cut off and glued.

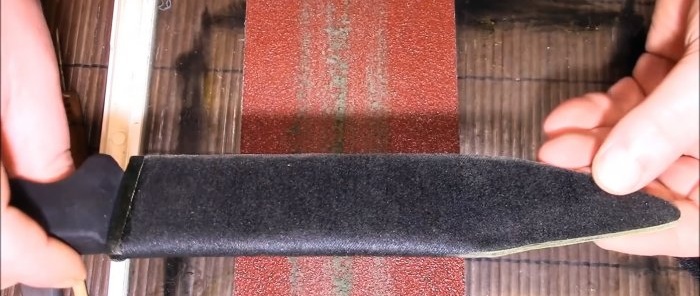

When the sheath is completely dry, you need to sand it on the cuts with coarse sandpaper.

Then they are tinted again with the ink mixture. You can also make a belt loop from leftover fabric.It is made from a strip folded several times and glued to the sheath.

It is recommended to leave the made sheath for a week to complete the chemical reaction between the chromium and PVA, so that the impregnation becomes completely waterproof. After drying, the sheath is washed with water to wash away any remaining unreacted chromium. This will prevent it from causing yellow stains on clothes during the first rain.

The two-layer sheath, glued in this order, turns out to be very rigid, which is what is required of them. If you are making a phone case, then on the contrary, you need moderate flexibility. To do this, add a couple of drops of pharmaceutical glycerin to the impregnating composition. The thicker the glue used, the more glycerin needs to be poured.

What you will need:

- denim or cotton;

- water-soluble ink or color for paint;

- PVA glue;

- deep penetration primer for walls;

- chrome peak.

Scabbard manufacturing process

Cotton or denim should be used as a blank for the sheath. You can simply cut a piece from old jeans. Then it needs to be soaked. The impregnation composition includes PVA glue and deep penetration primer for impregnation of walls in a 50:50 ratio.

Also, the required amount of ink of the desired color or color scheme for paints is added to the mixture.

The fabric is brushed and dried.

For the second impregnation, a little chromium is added to the composition to increase its water resistance. This component can be purchased inexpensively at a chemical store.

The piece of fabric is soaked and dried after each layer until it becomes as tough as leather.

To speed up the process, the layers can be dried with a hair dryer.

Next, a knife blade is applied to the edge of the fabric. It is cut along its contour. Then an indent of 4-5 mm is made from the cut edge, and the material is bent along the spine of the blade. It is then cut along the previously trimmed edge.

To increase rigidity, the cut out workpiece is coated from the inside with a mixture of PVA with a pinch of chromium. This is a thick mass, so it is difficult to spread it with a brush. To do this, use a spatula or plastic card.

After the glue has dried, you need to take a little PVA mixture from the chromium pins into a syringe, and apply it along the edge of the workpiece to glue the layers. It is important that there is a small gap between the blade and the glue seam. The composition will set in half an hour.

Next, you need to trim the nose part of the sheath from the side of the butt, where the blade does not reach. The cut is made slightly short of the knife. Then PVA with chrome peak is applied on it from the inside.

From the side where the blade enters, the sheath needs to be trimmed by 3-4 mm along the sides and a fold should be made. Then the outer surface of the sheath and the remaining unused piece of fabric are coated with a strengthening compound, but only on one side.

After the composition has dried, it is applied again to glue the second layer of fabric to the sheath. You also need to glue the hem at the entrance of the sheath. After drying the glue with a hairdryer, you can trim it. Excess fabric on the nose is also cut off and glued.

When the sheath is completely dry, you need to sand it on the cuts with coarse sandpaper.

Then they are tinted again with the ink mixture. You can also make a belt loop from leftover fabric.It is made from a strip folded several times and glued to the sheath.

It is recommended to leave the made sheath for a week to complete the chemical reaction between the chromium and PVA, so that the impregnation becomes completely waterproof. After drying, the sheath is washed with water to wash away any remaining unreacted chromium. This will prevent it from causing yellow stains on clothes during the first rain.

The two-layer sheath, glued in this order, turns out to be very rigid, which is what is required of them. If you are making a phone case, then on the contrary, you need moderate flexibility. To do this, add a couple of drops of pharmaceutical glycerin to the impregnating composition. The thicker the glue used, the more glycerin needs to be poured.

Watch the video

Similar master classes

Particularly interesting

Comments (0)