How to make a roof from plastic bottles

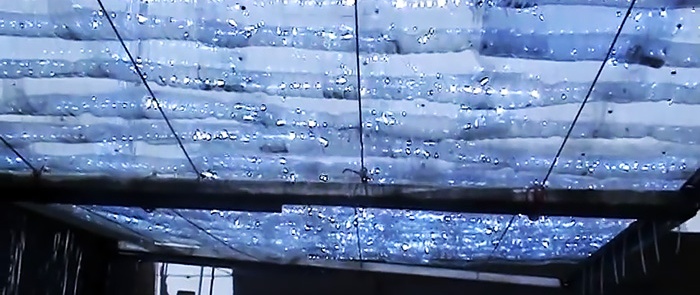

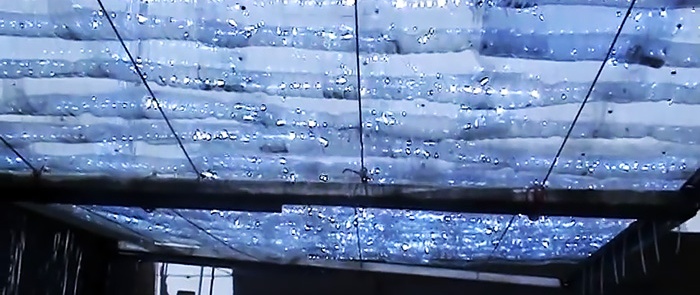

If you need to make a transparent rain canopy, cover an outbuilding or greenhouse, you can use homemade roofing material consisting of PET bottles. The technology for its production is very simple and quite fast, so if you have accumulated a large number of bottles, you can put them to use and get practically free roofing.

The proposed technology involves the production of a wavy roof similar to slate or ondulin. To make it quite neat, it is advisable to use identical PET bottles. As a last resort, you can sort them and use identical bottles to make one wave.

To make roofing material, you need to evenly and accurately cut off the bottoms and pots of the bottles.

Then the remaining cylinders are cut lengthwise into 2 waves.

Having prepared a sufficient number of bottle halves, they need to be connected into long waves. To do this, they are folded with an overlap of several centimeters.On the sides, their double walls are connected by brackets. A stationery stapler is used for this. Each connection uses 2 staples. In this way, the halves are built up until a long wave equal to the roof slope is obtained.

Having prepared a sufficient number of waves, you need to connect them. To do this, they are applied parallel to each other. In this case, one wave should be turned outward, and the second inward. Together they seem to repeat the slate relief. After laying out the waves need to be connected. To do this, holes are melted in them with a hot soldering iron, and adjacent strips are pulled together with rivets.

The roof, after joining the strips with rivets, is a single contour. This allows it to be laid on the sheathing with a wide step between the stops.

This is a very important quality for sheltering a greenhouse or building a rain canopy, since the thin sheathing minimizes the loss of sunlight. Another advantage of the material, in addition to transparency and freeness, is the ease of installation on complex bevels. It is easy to trim and bend. Due to the elasticity of the wave, in some places it can be expanded or narrowed. You can easily connect roofing sheets with different wave directions. The main thing is to ensure that during installation there is a sufficient slope for the flow of water to prevent it from stagnating in the center, which will inevitably result in a leak.

Materials:

- plastic bottles;

- staples for a stationery stapler;

- blind rivets.

Roofing material manufacturing process

The proposed technology involves the production of a wavy roof similar to slate or ondulin. To make it quite neat, it is advisable to use identical PET bottles. As a last resort, you can sort them and use identical bottles to make one wave.

To make roofing material, you need to evenly and accurately cut off the bottoms and pots of the bottles.

Then the remaining cylinders are cut lengthwise into 2 waves.

Having prepared a sufficient number of bottle halves, they need to be connected into long waves. To do this, they are folded with an overlap of several centimeters.On the sides, their double walls are connected by brackets. A stationery stapler is used for this. Each connection uses 2 staples. In this way, the halves are built up until a long wave equal to the roof slope is obtained.

Having prepared a sufficient number of waves, you need to connect them. To do this, they are applied parallel to each other. In this case, one wave should be turned outward, and the second inward. Together they seem to repeat the slate relief. After laying out the waves need to be connected. To do this, holes are melted in them with a hot soldering iron, and adjacent strips are pulled together with rivets.

The roof, after joining the strips with rivets, is a single contour. This allows it to be laid on the sheathing with a wide step between the stops.

This is a very important quality for sheltering a greenhouse or building a rain canopy, since the thin sheathing minimizes the loss of sunlight. Another advantage of the material, in addition to transparency and freeness, is the ease of installation on complex bevels. It is easy to trim and bend. Due to the elasticity of the wave, in some places it can be expanded or narrowed. You can easily connect roofing sheets with different wave directions. The main thing is to ensure that during installation there is a sufficient slope for the flow of water to prevent it from stagnating in the center, which will inevitably result in a leak.

Watch the video

Similar master classes

Particularly interesting

Comments (2)