How to make a pump for a screwdriver

A screwdriver, when equipped with the appropriate attachment, can be used to solve a wide variety of, and even unexpected, problems. An example of such a non-standard use would be its use for pumping water. To do this, you just need to make a special pump attachment.

The water pump housing is made from a piece of sewer pipe 40 mm long. On the one hand, it needs to be muffled. To do this, you can unravel another section of pipe lengthwise, align it using a hair dryer, cut out the plug from the resulting plate and glue it onto the workpiece. Then a hole for the shaft is drilled in the center of the plug.

A ring cut from any tube whose inner diameter corresponds to the size of the outer race of the selected bearing is glued onto the outer side of the plug.

After the glue hardens, the bearing is pressed into the ring.

On the side of the body, 2 holes are made in the center opposite each other.

A 1/2-inch piece of pipe is inserted into them. External joints are glued with epoxy glue, since loads will be placed on these elements in the future.

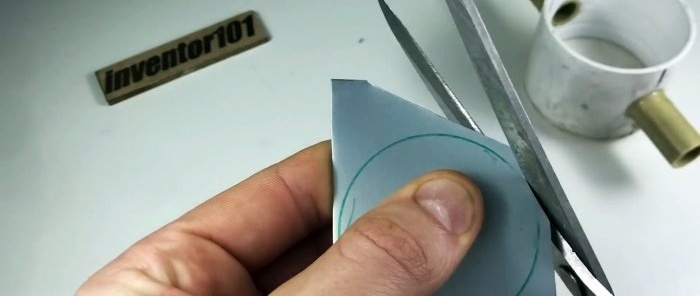

A disk with a diameter of 48 mm is cut out of tin or thin sheet metal.

A hole is drilled in its center.

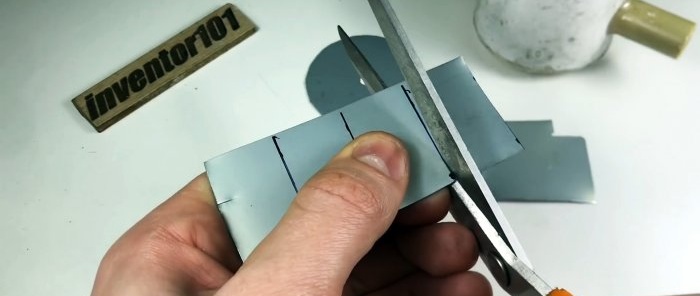

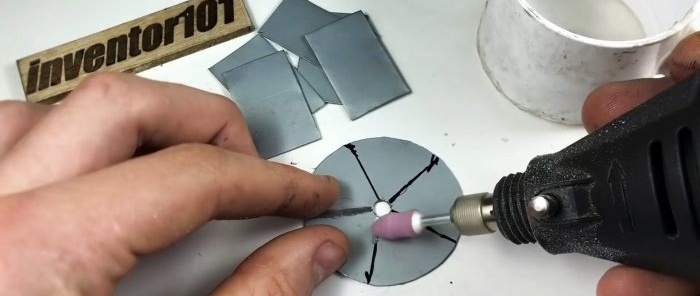

It is divided into 5 sectors. 5 20x30 mm plates are cut from the same sheet. Next you need to clean their edges and markings on the disk. Then a shaft is inserted into the disk, and the plates are soldered according to the markings.

The result is an impeller.

A round gasket is cut from the chamber into the pump body.

A hole of slightly smaller diameter than the shaft on the impeller is drilled into it. The gasket is then glued onto the plug from the inside of the housing.

Next, the impeller is inserted into the housing, and it is sealed with a second plug made of sheet plastic.

A garden hose is pulled onto the pump tubes, and its shaft is clamped in the chuck of a drill or screwdriver.

To use the pump, you need to dip one end of the hose in water and start rotating the impeller with a screwdriver. It will create a pressure discharge and lift water into the housing, after which it will be pumped further to the outlet hose. The performance of the pump depends on the rotation speed of the screwdriver. The higher the speed, the more water you can pump.

Materials:

- plastic sewer pipe 50 mm;

- 1/2 inch plastic water pipe;

- old tire tube;

- tin or thin sheet metal;

- shaft 5 mm (piece of rod);

- mini bearing with an inner race diameter of 5 mm.

Pump manufacturing process

The water pump housing is made from a piece of sewer pipe 40 mm long. On the one hand, it needs to be muffled. To do this, you can unravel another section of pipe lengthwise, align it using a hair dryer, cut out the plug from the resulting plate and glue it onto the workpiece. Then a hole for the shaft is drilled in the center of the plug.

A ring cut from any tube whose inner diameter corresponds to the size of the outer race of the selected bearing is glued onto the outer side of the plug.

After the glue hardens, the bearing is pressed into the ring.

On the side of the body, 2 holes are made in the center opposite each other.

A 1/2-inch piece of pipe is inserted into them. External joints are glued with epoxy glue, since loads will be placed on these elements in the future.

A disk with a diameter of 48 mm is cut out of tin or thin sheet metal.

A hole is drilled in its center.

It is divided into 5 sectors. 5 20x30 mm plates are cut from the same sheet. Next you need to clean their edges and markings on the disk. Then a shaft is inserted into the disk, and the plates are soldered according to the markings.

The result is an impeller.

A round gasket is cut from the chamber into the pump body.

A hole of slightly smaller diameter than the shaft on the impeller is drilled into it. The gasket is then glued onto the plug from the inside of the housing.

Next, the impeller is inserted into the housing, and it is sealed with a second plug made of sheet plastic.

A garden hose is pulled onto the pump tubes, and its shaft is clamped in the chuck of a drill or screwdriver.

To use the pump, you need to dip one end of the hose in water and start rotating the impeller with a screwdriver. It will create a pressure discharge and lift water into the housing, after which it will be pumped further to the outlet hose. The performance of the pump depends on the rotation speed of the screwdriver. The higher the speed, the more water you can pump.

Watch the video

Similar master classes

Particularly interesting

Comments (0)