How to install a drill chuck on an angle grinder and why it might be useful

This need quite often arises when you need to drill a hole in a place that is difficult or impossible to get to with a conventional drill. If you install a drill chuck on an angle grinder, then thanks to the angle gear, you can successfully carry out this operation in the most cramped working conditions.

However, it should be borne in mind that an angle grinder and a drill differ both in design and in operational characteristics. If you do not take these factors into account, you can quickly “seat” the drill or, even worse, ruin the workpiece.

To implement the planned symbiosis, in addition to the grinder, we will need:

To carry out this work, it is enough to have some metalworking skills and the most common tools and devices.

We remove the washer from the spindle shaft that is placed under the grinder’s equipment before tightening.

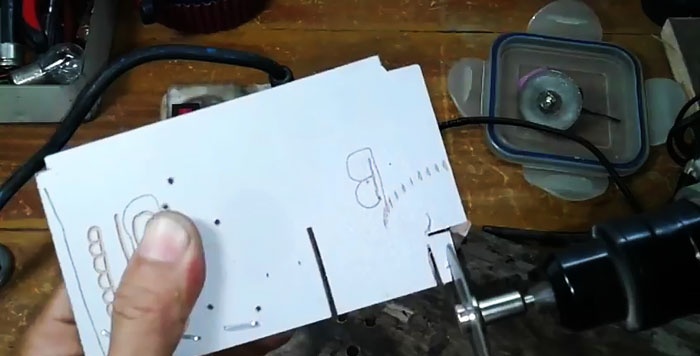

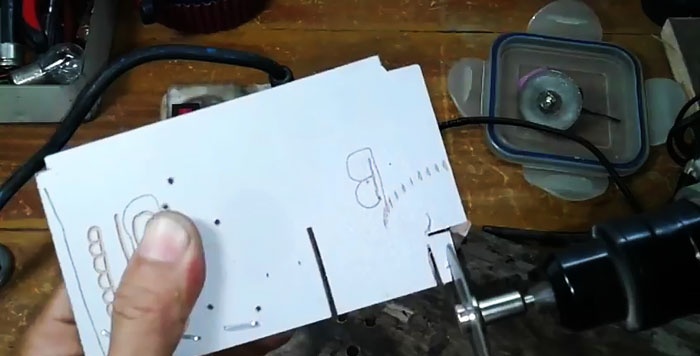

Using a thread template, we measure the thread pitch on the spindle shaft, which turned out to be 1.25 mm. Then its general designation will be M14×1.25 mm.

The mounting hole of the most common standard drill chucks has an internal M12 thread. It turns out there is an obvious discrepancy with the threads on the spindle shaft of the angle grinder.

In order to coordinate these two parts with each other, we drill out the metric thread in the drill chuck to M14 × 1.25 mm and, using a hand tap with the same geometric and cutting characteristics, cut the thread in the chuck.

The drill chuck can now be precisely, firmly and securely mounted on the threaded shaft of the spindle of the universal grinder.

It would also be quite useful to pay attention to the range of rotation speeds of the angle grinder spindle, which varies depending on the given mode from 6 to 12 thousand revolutions per minute. At the same time, for the ubiquitous twist drills, the most suitable speeds are 250-1200 rpm.

To match the speed of the angle grinder and the tools fixed in the chuck, the angle grinder must be connected to the network through an electric speed controller, with the help of which the spindle rotation speed can be adjusted and changed, both in the direction of decreasing and increasing.

It is not difficult to assemble it, read how -https://home.washerhouse.com/en/4447-kak-sdelat-regulyator-moschnosti-dlya-bytovyh-priborov.html

Now, having secured the drill in the chuck and set the optimal speed for drilling in the wood, we can use a grinder to make holes as easily as with a conventional drill.

We replace the drill in the chuck with a cutting disc, and having set the required speed for this equipment, we carry out the operation of cutting sheet material (plastic, tin, cardboard, etc.).

By installing a grinding wheel on the grinder's spindle and setting an increased speed using the speed controller, we can quickly and efficiently sharpen a twist drill.

By replacing the grinding wheel with a roughing wheel, at the same speed, we can easily tidy up the tip of the chisel, pry bar, etc.

Once installed in the cutter chuck, you can process edges and chamfers on wood, plastic and soft metal parts with ease and high productivity.

By fixing the polishing equipment in the chuck, we can polish any metal surface to a shine.

So, installing a drill chuck on an angle grinder not only gives this tool the functions of a drill, but also allows you to perform many operations in places that are inaccessible to it.

However, it should be borne in mind that an angle grinder and a drill differ both in design and in operational characteristics. If you do not take these factors into account, you can quickly “seat” the drill or, even worse, ruin the workpiece.

Will need

To implement the planned symbiosis, in addition to the grinder, we will need:

- drill chuck;

- thread template;

- tap M14×1.25 mm with a knob;

- twist drill and other working attachments;

- electric speed controller.

The sequence of installing a drill chuck on an angle grinder

To carry out this work, it is enough to have some metalworking skills and the most common tools and devices.

Installing the chuck on the angle grinder spindle

We remove the washer from the spindle shaft that is placed under the grinder’s equipment before tightening.

Using a thread template, we measure the thread pitch on the spindle shaft, which turned out to be 1.25 mm. Then its general designation will be M14×1.25 mm.

The mounting hole of the most common standard drill chucks has an internal M12 thread. It turns out there is an obvious discrepancy with the threads on the spindle shaft of the angle grinder.

In order to coordinate these two parts with each other, we drill out the metric thread in the drill chuck to M14 × 1.25 mm and, using a hand tap with the same geometric and cutting characteristics, cut the thread in the chuck.

The drill chuck can now be precisely, firmly and securely mounted on the threaded shaft of the spindle of the universal grinder.

The need for a speed controller

It would also be quite useful to pay attention to the range of rotation speeds of the angle grinder spindle, which varies depending on the given mode from 6 to 12 thousand revolutions per minute. At the same time, for the ubiquitous twist drills, the most suitable speeds are 250-1200 rpm.

To match the speed of the angle grinder and the tools fixed in the chuck, the angle grinder must be connected to the network through an electric speed controller, with the help of which the spindle rotation speed can be adjusted and changed, both in the direction of decreasing and increasing.

It is not difficult to assemble it, read how -https://home.washerhouse.com/en/4447-kak-sdelat-regulyator-moschnosti-dlya-bytovyh-priborov.html

Practical results of installing a cartridge on an angle grinder

Now, having secured the drill in the chuck and set the optimal speed for drilling in the wood, we can use a grinder to make holes as easily as with a conventional drill.

We replace the drill in the chuck with a cutting disc, and having set the required speed for this equipment, we carry out the operation of cutting sheet material (plastic, tin, cardboard, etc.).

By installing a grinding wheel on the grinder's spindle and setting an increased speed using the speed controller, we can quickly and efficiently sharpen a twist drill.

By replacing the grinding wheel with a roughing wheel, at the same speed, we can easily tidy up the tip of the chisel, pry bar, etc.

Once installed in the cutter chuck, you can process edges and chamfers on wood, plastic and soft metal parts with ease and high productivity.

By fixing the polishing equipment in the chuck, we can polish any metal surface to a shine.

So, installing a drill chuck on an angle grinder not only gives this tool the functions of a drill, but also allows you to perform many operations in places that are inaccessible to it.

Watch the video

Similar master classes

How to remove a pressed pulley from an electric motor and install

How to disassemble and lubricate a drill chuck

How to replace a worn chuck with a new one on a drill

How to easily hide a self-tapping screw in wood

Drilling machine centering attachment for precision drilling

How to eliminate chuck runout in a screwdriver

Particularly interesting

Comments (2)