How to make a powerful juicer from a washing machine

The drum from the washing machine is made of stainless steel, which allows it to be used as a base for assembling a centrifugal juicer capable of pressing fruit juice on an almost industrial scale. The resulting apparatus allows you to simultaneously grind juice-containing raw materials into puree and immediately separate the juice from it, which is much more convenient than using a press.

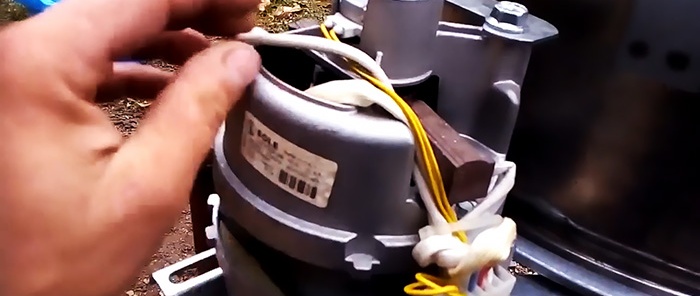

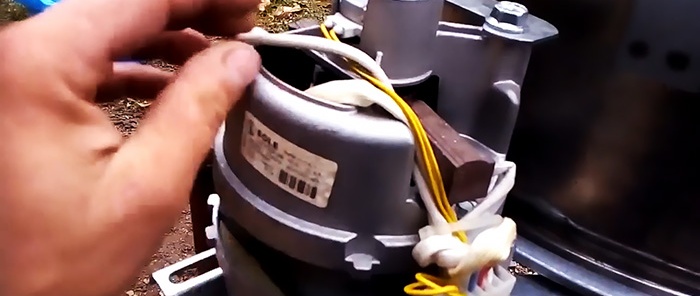

The tub with the drum and the motor are removed from the washing machine. The side counterweights are left in place. The tank and drum are thoroughly washed. To connect the motor, you need to cut 2 wires from the speed sensor. Then, from the remaining four wires, you need to find those connected to the motor brushes, and a pair going to its stator. Next, you need to connect together one wire from the stator and one from the brushes.A cable with a plug is screwed onto the remaining ones for connection to a 220V network.

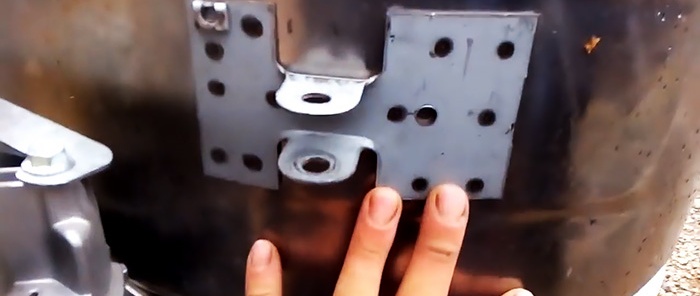

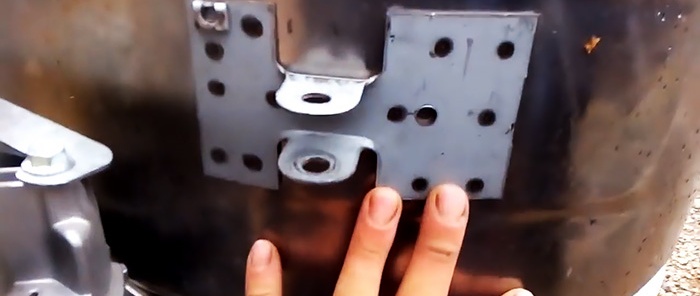

A frame is welded from a corner or profile pipe to install a drum with a motor. The drum is attached with the loading hole facing up. The height of the frame should allow you to place a bucket underneath the juicer.

The holes in the drum tank must be closed. To do this, patches are cut out from the walls of the donor pan and installed on stainless rivets.

A round hole is made in the bottom of the tank and a tube is tightly inserted into it, through which the juice will flow into the substituted bucket.

The bottom of the pan used for patches is cut off. It is densely perforated from the inside with a sharp punch to obtain a fine grater. When punching, a wooden block or board is placed under the pan. Then the bottom is screwed to the center of the drum using 3 corners. It is important to maintain a gap between the grater and the drum so that the grated puree can fall out freely.

Next, the guide device is made. It is a piece of plastic pipe equal to the diameter of the pan. Squares are attached to it with rivets, which cling to the standard eyes on the front of the tank. The bottom of the pipe does not reach the bottom of the pan by 5 mm.

The principle of operation of the juicer is as follows (see clearly in the video below). Fruits (apples, pears) are poured inside through a guide pipe. A rotating grater rubs them into a puree, and due to centrifugal force, it sticks to the walls of the drum. The juice contained in the puree flows into the tank and flows through the tube into the bucket. During operation, the juicer periodically stops and the accumulated dry pulp is removed from the drum.

To ensure that less softness gets into the juice, you can apply a steamed, damp sheet to the walls of the drum before work. It will stick and hold on.After squeezing out the juice, the sheet is removed along with the pulp, and the walls underneath will be clean.

Device:

Trial:

Materials:

- old drum washing machine;

- thin-walled stainless steel pan;

- stainless steel blind rivets;

- plastic pipe the size of the pan;

- profile pipe or corner.

Juicer manufacturing process

The tub with the drum and the motor are removed from the washing machine. The side counterweights are left in place. The tank and drum are thoroughly washed. To connect the motor, you need to cut 2 wires from the speed sensor. Then, from the remaining four wires, you need to find those connected to the motor brushes, and a pair going to its stator. Next, you need to connect together one wire from the stator and one from the brushes.A cable with a plug is screwed onto the remaining ones for connection to a 220V network.

A frame is welded from a corner or profile pipe to install a drum with a motor. The drum is attached with the loading hole facing up. The height of the frame should allow you to place a bucket underneath the juicer.

The holes in the drum tank must be closed. To do this, patches are cut out from the walls of the donor pan and installed on stainless rivets.

A round hole is made in the bottom of the tank and a tube is tightly inserted into it, through which the juice will flow into the substituted bucket.

The bottom of the pan used for patches is cut off. It is densely perforated from the inside with a sharp punch to obtain a fine grater. When punching, a wooden block or board is placed under the pan. Then the bottom is screwed to the center of the drum using 3 corners. It is important to maintain a gap between the grater and the drum so that the grated puree can fall out freely.

Next, the guide device is made. It is a piece of plastic pipe equal to the diameter of the pan. Squares are attached to it with rivets, which cling to the standard eyes on the front of the tank. The bottom of the pipe does not reach the bottom of the pan by 5 mm.

The principle of operation of the juicer is as follows (see clearly in the video below). Fruits (apples, pears) are poured inside through a guide pipe. A rotating grater rubs them into a puree, and due to centrifugal force, it sticks to the walls of the drum. The juice contained in the puree flows into the tank and flows through the tube into the bucket. During operation, the juicer periodically stops and the accumulated dry pulp is removed from the drum.

To ensure that less softness gets into the juice, you can apply a steamed, damp sheet to the walls of the drum before work. It will stick and hold on.After squeezing out the juice, the sheet is removed along with the pulp, and the walls underneath will be clean.

Watch the video

Device:

Trial:

Similar master classes

How to connect the motor from a washing machine to 220 V

How to remove small objects caught in the washing machine from

Submersible pump from a washing machine pump

Sharpener from a washing machine engine

How to make a lawn mower from a washing machine

How to make a drilling machine from a jack and a washing machine motor

Particularly interesting

Comments (1)