How to make a high-speed engine from a bolt and nut

As a drive for various homemade products, you may need a compact high-speed DC electric motor. If you have a thin enameled wire and two small magnets, it is easy to make with your own hands. It can work perfectly both from a battery and a car battery.

Materials:

- M10 bolt with nut;

- enameled copper wire 0.2 mm;

- Super glue;

- insulating tape;

- Fiberboard;

- thin metal rod;

- mini bearings – 2 pcs.;

- magnets – 2 pcs.;

- thin wire without insulation.

Engine manufacturing process

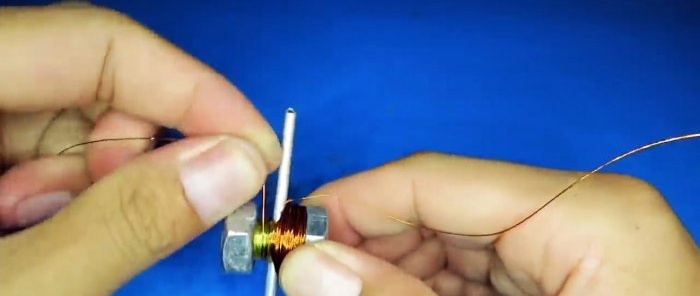

A nut is attached to a short bolt. Next, it must be drilled crosswise in the center between the nut and the head.

The hole is cleared of burrs, then the nut is glued with superglue, and electrical tape is wound onto the open thread.

A rod 50-70 mm long is inserted into the hole and also fixed with glue.

The result is an armature motor with an axis of rotation. It is necessary to wind 400 turns of 0.2 mm enameled wire on it. 200 turns are made on both sides of the rod.

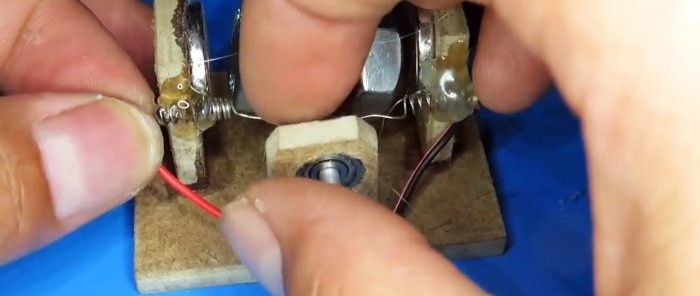

2 L-shaped contacts are cut out of thin sheet metal and glued to the armature axis.The stripped winding wires are soldered to them.

2 racks with holes are cut out of fiberboard into which bearings are glued. The posts are glued to the fiberboard base, and the axle is inserted into the bearings. It is important that the height of the posts is sufficient to rotate the anchor. It should not reach the sole.

The stator for the motor will be 2 pieces of fiberboard with magnets glued on top. They are glued with opposite sides of the polarity. Magnets with pieces of fiberboard are fixed on the sole with sufficient indentation so that the rotating armature does not touch them.

2 spirals are twisted from wire without insulation. A wire is soldered to them on one side, and a long tail is left on the other. The spirals are glued with hot glue to racks with magnets. In this case, the tails should touch the contacts on the rotor axis from above and below. The result is something like brushes.

Now, when power is applied, the motor armature begins to rotate. At a voltage of 12.5 V, the motor produces 21 thousand rpm. If you connect it to a 3.7V battery, you get 5.7 thousand rpm.

Due to the massiveness and elongation of the armature, during acceleration the engine has a high tractive force for its size. Of course, if it is used as a drive for a serious mechanism, the case should be assembled not with glue, but with racks and magnets attached more thoroughly.

Watch the video

Similar master classes

Particularly interesting

Comments (1)