How to make a heavy-duty arched box from angle steel

A vaulted door frame made from a steel corner, in addition to its original appearance, is durable, which is not superfluous today. It will not cost much, since the costs will mainly be related to the cost of the corner and not necessarily a new one. Any adult with the skills of a welder and mechanic can handle the job.

Will need

The only materials needed are a steel angle and a strip. Necessary tools and equipment:- ruler, chalk, tape measure;

- construction cord;

- Circular Saw;

- device for bending a corner;

- welding machine;

- grinder with attachments.

The process of making a vaulted door frame from angle steel

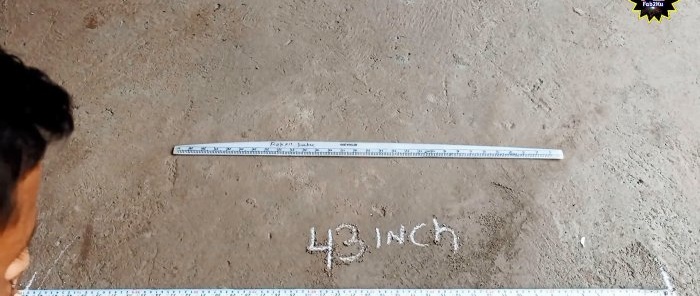

We draw a straight line 110 cm long on a flat surface. Depending on the width of the door frame, the line can be shortened or, conversely, extended. We mark the middle on the 110 cm line - 55 cm.

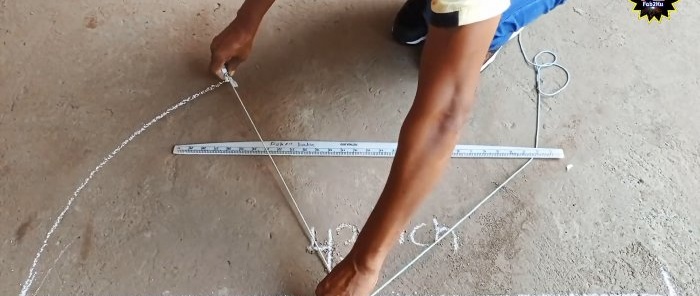

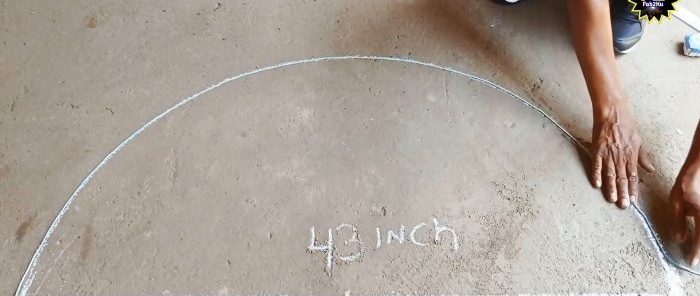

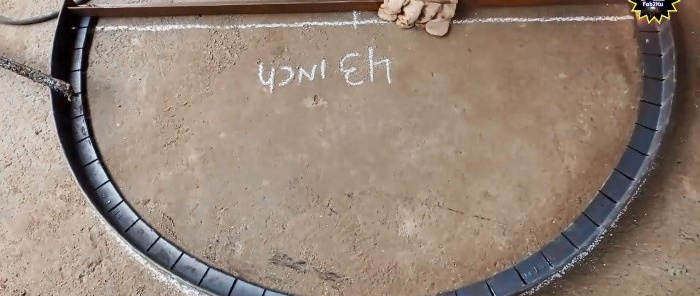

We hold one end of the cord in the center of the line and use chalk tied to the other end as a radius to draw a semicircle resting on the line of 110 cm, which is actually the diameter (D).

We carefully lay the longer construction cord along the semicircle line from the starting point to the ending point. We measure the length of the laid cord with a tape measure, which turned out to be 173 cm.

You can do without a cord and simply calculate the length of the semicircle (L) according to the dependence: L=π D/2= 3.1415×110/2=172.78 cm or rounded 173 cm. This should be the length of the right angle from which we assemble make a door frame arch.

We select a corner 45×45×5 mm and a length of 175 cm, i.e. with a small margin, and make marks on it in increments of 5 cm, 35 marks in total.

Using a circular saw, we make 35 vertical slots on one of the corner shelves using the marks.

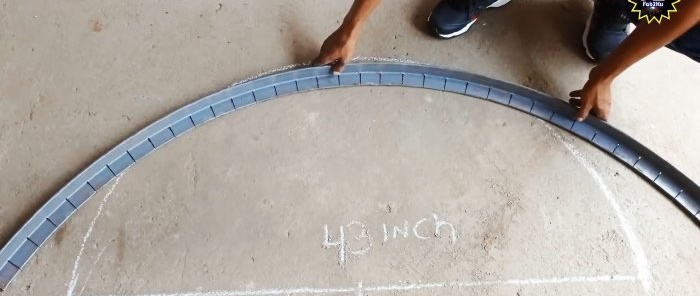

Using a simple device made from a channel and two round rods, welded offset to the back from the outside, we bend the corner into an arc until the outer edges of all the slots converge. We lay the arch blank on the marking and make sure that the bending radius is still large.

Using a circular saw again, we open the slots in their upper part and continue to bend the corner to reduce the bending radius.

We place the corner bent in two steps onto the marking and make sure that it has taken on the desired curvature, since it completely coincides with the marking along its entire length. We temporarily tighten the ends of the arch from the corner with another corner using tacks and weld all the slots on both sides. We remove the slag and clean the seams with a grinder.

We remove the corner using tacks and weld the box posts from the same corner as the arch to the ends of the arch from the corner. Instead of a threshold, we use a strip of steel 110 cm long, which we weld to the lower ends of the racks.

To embed the door frame into the wall, we weld pieces of angle iron of the required length to the studs from the outside in the plane of the frame.

Watch the video

Similar master classes