How to make a simple 220V generator with your own hands

For most people, a homemade generator is associated with a converted electric motor. In fact, it can be done differently, literally from scratch. Moreover, it is absolutely not difficult, fast and inexpensive.

It is necessary to make 2 cores for winding wire. To do this, you need to line up 3 bolts in a row and glue their heads together with superglue.

Between their rods, trimming pins are placed and also glued.

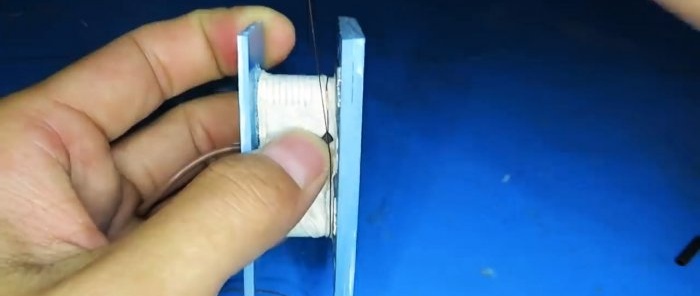

4 identical plates are cut out of sheet plastic and glued together in pairs. Then a cut is made in them for gluing in the cores from the side of the bolt heads.

2 more smaller plates are cut out and glued to the cores opposite. The resulting coils are insulated.

The wiring is soldered to the copper wire. The connection is insulated with heat shrink.

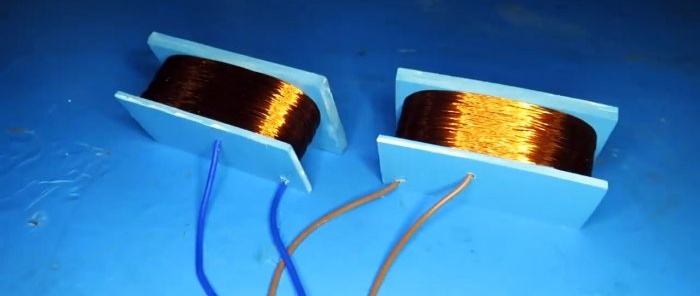

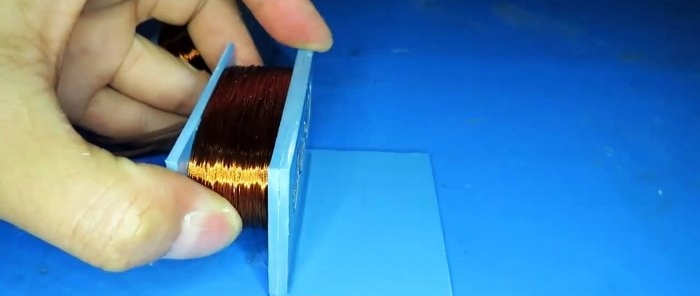

After this, you need to wind the copper wire around the core.To do this, you will first need to thread the wire through the single plate, after drilling it. It is important to wind as many turns as possible. Wiring is also soldered to the remaining end of the wire. The second coil is made in the same way.

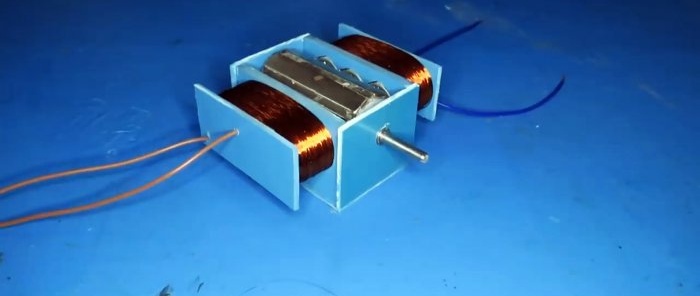

One of the coils is glued to the plate.

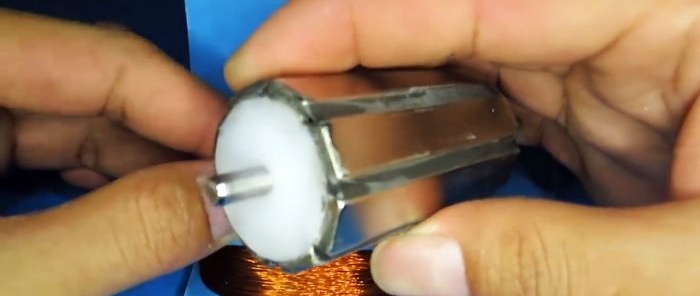

Then you need to make the generator rotor. It is a wooden or plastic cylinder with neodymium magnets in the form of strips glued in a circle.

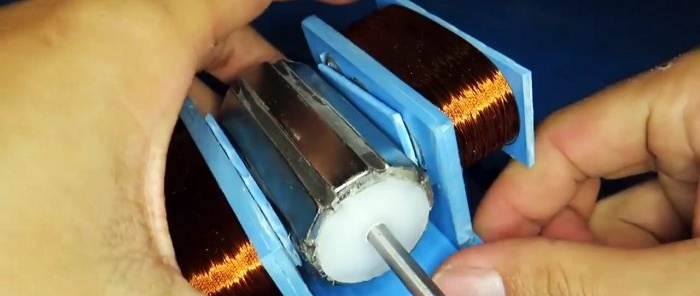

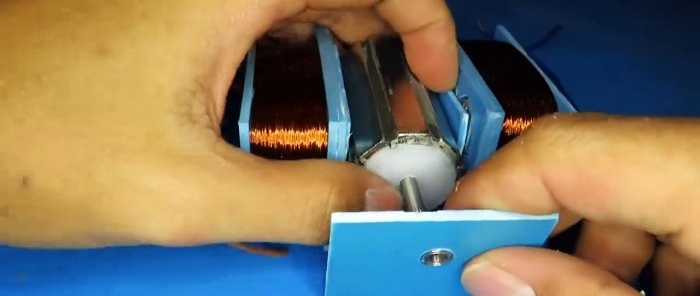

You need to glue 8 magnets, with alternating polarities. A through hole is made in the center of the cylinder and a rod axle is driven into it. The rotor is applied to the glued coil through the substrate. Then a second coil is glued to the base, also separated from the rotor by an insert.

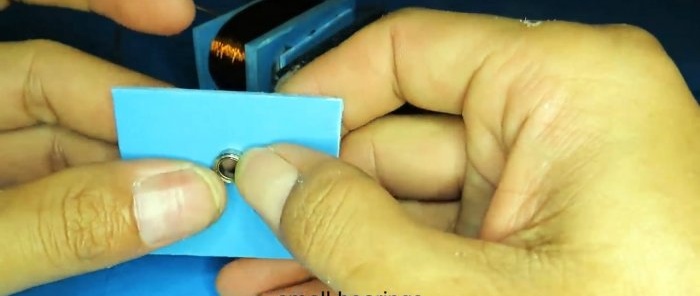

Next, the rotor axis holders are glued. You need to make holes in them in advance and glue them into the bearings. The substrates are then removed to allow the rotor to rotate freely.

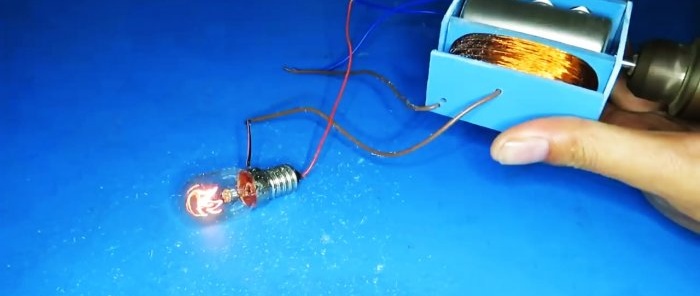

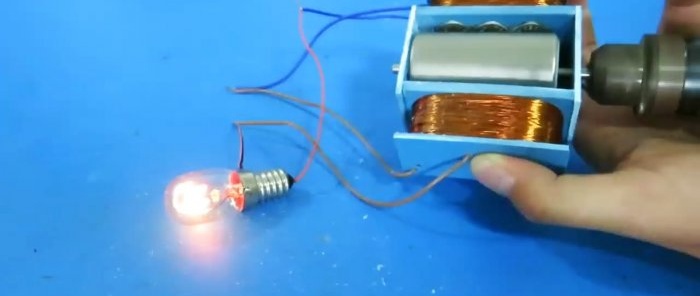

You need to connect one wire from each coil. Now, when the armature rotates, an electric current will be generated. It can be removed on the remaining two wires. During testing, when rotating the rotor with a drill, it was possible to obtain enough to light a 35 W light bulb. In the future, such a generator can be placed in a sealed housing and blades can be placed on it so that it rotates due to gusts of wind or the movement of water flow in a stream.

Basic materials:

- sheet plastic;

- bolts M10-M14;

- stud M6-M8;

- enameled copper wire 0.25 mm;

- stranded wire;

- micro bearings 5x10x4 mm – 2 pcs. -

- neodymium magnets 60x10x4 mm – 8 pcs. -

Generator manufacturing process

It is necessary to make 2 cores for winding wire. To do this, you need to line up 3 bolts in a row and glue their heads together with superglue.

Between their rods, trimming pins are placed and also glued.

4 identical plates are cut out of sheet plastic and glued together in pairs. Then a cut is made in them for gluing in the cores from the side of the bolt heads.

2 more smaller plates are cut out and glued to the cores opposite. The resulting coils are insulated.

The wiring is soldered to the copper wire. The connection is insulated with heat shrink.

After this, you need to wind the copper wire around the core.To do this, you will first need to thread the wire through the single plate, after drilling it. It is important to wind as many turns as possible. Wiring is also soldered to the remaining end of the wire. The second coil is made in the same way.

One of the coils is glued to the plate.

Then you need to make the generator rotor. It is a wooden or plastic cylinder with neodymium magnets in the form of strips glued in a circle.

You need to glue 8 magnets, with alternating polarities. A through hole is made in the center of the cylinder and a rod axle is driven into it. The rotor is applied to the glued coil through the substrate. Then a second coil is glued to the base, also separated from the rotor by an insert.

Next, the rotor axis holders are glued. You need to make holes in them in advance and glue them into the bearings. The substrates are then removed to allow the rotor to rotate freely.

You need to connect one wire from each coil. Now, when the armature rotates, an electric current will be generated. It can be removed on the remaining two wires. During testing, when rotating the rotor with a drill, it was possible to obtain enough to light a 35 W light bulb. In the future, such a generator can be placed in a sealed housing and blades can be placed on it so that it rotates due to gusts of wind or the movement of water flow in a stream.

Watch the video

Similar master classes

Particularly interesting

Comments (1)