How to make a penny pipe cutter from PVC pipes and for PVC pipes

In order for the cut sewer pipe to fit into the socket, it must be chamfered. As a result, preparing each trim takes time. If you make a pipe cutter of this design, then each piece will immediately have a chamfer.

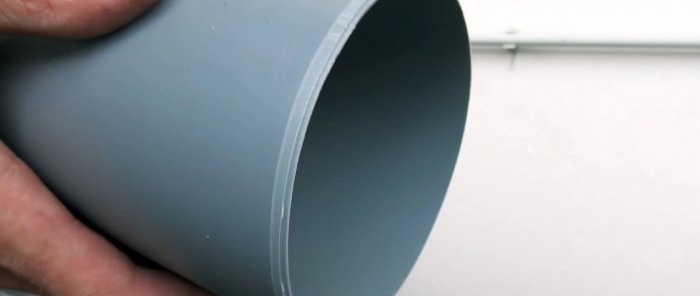

On the bell it is necessary to cut 4 petals 20 mm wide with the same distance from each other. They should go from the beginning of the bend to the narrowing of the socket to the diameter of the pipe. It is convenient to make holes at the boundaries of the markings and cut everything out with a jigsaw to them.

Next, you need to cut off the step at the entrance to the socket and remove the sealing gum. The petals must be heated with a burner and bent inside the bell.

Their protruding part on the back is cut off. The previously cut end is ground flat.

A dowel is inserted into the screwdriver handle. Then it is screwed onto the screw of the clamp.

You need to drill a 6 mm hole at the edge of one of the clamp's whiskers.

A triangular cutter is machined from a bit. It is pressed into the hole in the clamp with the tip inward. To prevent the plastic from splitting, it is better to do this in a vice rather than hitting it with a hammer.

To cut a pipe, you need to put a stopper from the socket on it. Next, the clamp is tightened and aligned with a cutter along the markings for cutting.

The clamp rotates on the pipe by the handle until the cutter almost passes through the wall. Finally, you need to cut the pipe with a mounting knife. As a result, the cut piece and the rest of the pipe will have a neat chamfer, so they can easily fit into the sockets.

Materials:

- enlarged clamp;

- an old screwdriver with a removable shaft;

- pipe socket 110 mm;

- flat bit for a screwdriver;

- plastic dowel.

Pipe cutter manufacturing process

On the bell it is necessary to cut 4 petals 20 mm wide with the same distance from each other. They should go from the beginning of the bend to the narrowing of the socket to the diameter of the pipe. It is convenient to make holes at the boundaries of the markings and cut everything out with a jigsaw to them.

Next, you need to cut off the step at the entrance to the socket and remove the sealing gum. The petals must be heated with a burner and bent inside the bell.

Their protruding part on the back is cut off. The previously cut end is ground flat.

A dowel is inserted into the screwdriver handle. Then it is screwed onto the screw of the clamp.

You need to drill a 6 mm hole at the edge of one of the clamp's whiskers.

A triangular cutter is machined from a bit. It is pressed into the hole in the clamp with the tip inward. To prevent the plastic from splitting, it is better to do this in a vice rather than hitting it with a hammer.

To cut a pipe, you need to put a stopper from the socket on it. Next, the clamp is tightened and aligned with a cutter along the markings for cutting.

The clamp rotates on the pipe by the handle until the cutter almost passes through the wall. Finally, you need to cut the pipe with a mounting knife. As a result, the cut piece and the rest of the pipe will have a neat chamfer, so they can easily fit into the sockets.

Watch the video

Similar master classes

Particularly interesting

How to install a socket if there are short wires left

How to eliminate gaps between the chimney and slate

How to mix an ultra-reliable solution for the oven that does not give

There will be no more cracks: What to add to concrete to make it

Never buy ball valves without checking with me

New technology for floor insulation with penoplex

Comments (0)