How to make a sealant gun for a screwdriver and make repairs comfortably

If you have to use sealant often and a lot, then it makes sense to make a gun driven by a screwdriver for it. It will become more comfortable to work with it, and you will forget about the numbness of your hand from squeezing the lever.

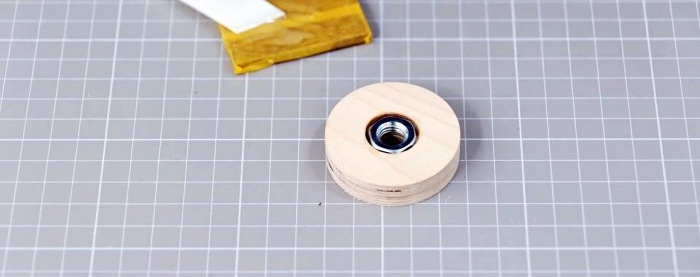

Using a core drill, you need to drill out a disk from plywood equal to the inner diameter of the sealant tube.

It should fit into it easily, so it can be sharpened if necessary. The center of the disk is expanded with a 10 mm drill. Then you need to partially drill the hole and glue an M10 nut into it with epoxy glue.

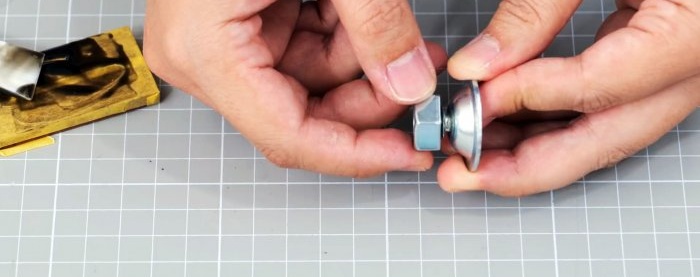

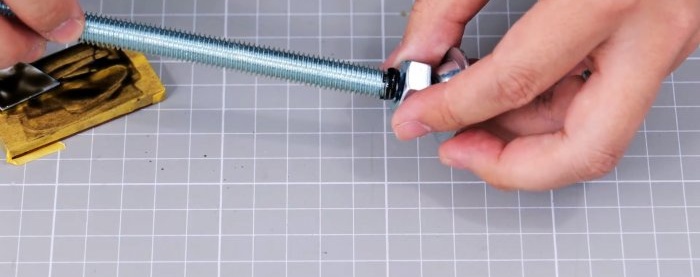

Next, you need to connect the threaded rod to the support plate from the clamp. This can be done without welding by simply shortening the plate screw and twisting it with the stud through the nut. For reliability, everything is mounted on thread locker or epoxy.

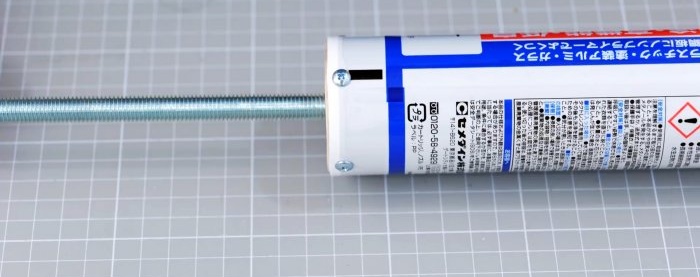

The pin is screwed into the plug from the side of the glued nut. To use sealant, the device is inserted into the tube, and the plug is screwed to it with 4 self-tapping screws.

Now if you clamp the free end of the pin in the screwdriver chuck, then when it rotates, the plate will press the piston in the tube. It is enough to set the minimum speed, and the sealant will be squeezed out smoothly, accurately and effortlessly.

Materials:

- plywood;

- threaded rod M10;

- nuts M10 – 2 pcs.;

- support plate with M10 thread.

Gun manufacturing process

Using a core drill, you need to drill out a disk from plywood equal to the inner diameter of the sealant tube.

It should fit into it easily, so it can be sharpened if necessary. The center of the disk is expanded with a 10 mm drill. Then you need to partially drill the hole and glue an M10 nut into it with epoxy glue.

Next, you need to connect the threaded rod to the support plate from the clamp. This can be done without welding by simply shortening the plate screw and twisting it with the stud through the nut. For reliability, everything is mounted on thread locker or epoxy.

The pin is screwed into the plug from the side of the glued nut. To use sealant, the device is inserted into the tube, and the plug is screwed to it with 4 self-tapping screws.

Now if you clamp the free end of the pin in the screwdriver chuck, then when it rotates, the plate will press the piston in the tube. It is enough to set the minimum speed, and the sealant will be squeezed out smoothly, accurately and effortlessly.

Watch the video

Similar master classes

Particularly interesting

How to install a socket if there are short wires left

How to eliminate gaps between the chimney and slate

How to mix an ultra-reliable solution for the oven that does not give

There will be no more cracks: What to add to concrete to make it

Never buy ball valves without checking with me

New technology for floor insulation with penoplex

Comments (0)