How to make a drill stand for a hand drill from a roller chain

For quick, comfortable drilling at right angles, you can make a drill stand for a drill. Many parts for this are easy to find at a metal receiving station, so the cost of a homemade product is several times lower than its factory counterpart.

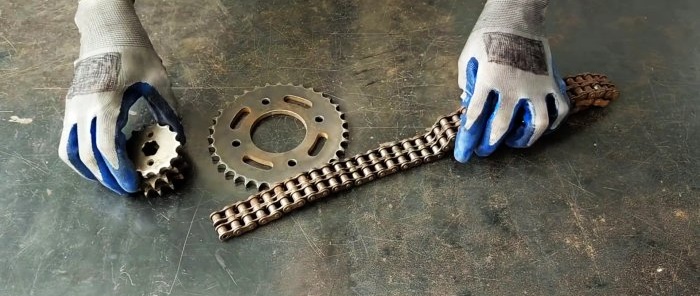

Basic materials:

- profile pipe 20 mm;

- double-row roller chain;

- double-row sprocket;

- corner 30x30 mm;

- strip 30 mm;

- rod 6-10 mm;

- bolts, nuts;

- extension springs – 2 pcs.

Drill stand manufacturing process

A frame for the sole of the machine is welded from a profile pipe.

2 crossbars made of a square rod are welded into it.

A section of 40-50 cm profile pipe is used as a machine stand. A double-row roller chain is welded to it.

Next you need to make a carriage with a mount for a drill. To do this, a U-shaped profile is welded onto a stand from a corner and a strip. When welding, you will need to place a sheet of paper between the parts to create a gap.

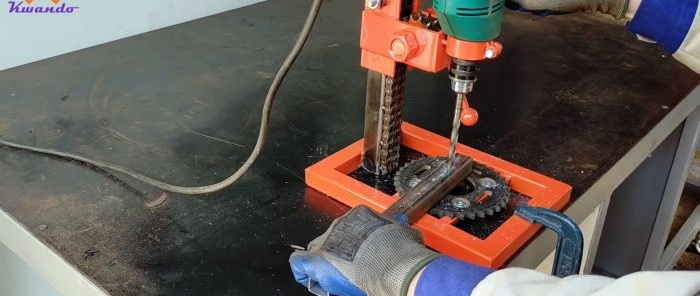

2 eyes with holes are made from the strip. A bolt with an asterisk is inserted into them. To prevent turning, they are welded.If the width of the sprocket is not enough, you will need to place washers on the sides of it. The lugs are welded to the carriage profile.

From the front side, the carriage is welded with a piece of strip. Small bolts are welded on the sides of the U-profile.

A clamp is made from a ring cut from a pipe onto the drill body at the location where the handle is installed. It is welded to the carriage.

3 rods with a headband of bearing balls are welded onto the head of the bolt holding the sprocket. At the point of convergence, a small star or washer is welded onto them for rigidity. This creates an adjustment wheel.

The stand is welded to the sole at a right angle. A carriage is put on it. At the top of the rack there is a through hole through which a pin is passed. Between it and the bolts on the carriage it is necessary to tighten 2 return springs.

The machine is being painted. A large star or plate is screwed to its base to form a support table. The drill is clamped in the clamp. That's it, the drilling machine is ready for use.

Watch the video

Similar master classes

A very simple drilling machine made from the most affordable materials

Drill stand for drill from old shock absorbers

How to make a simple machine for shaped cutting of metal from a drill

How to make a simple boat from PVC pipes and a trimmer engine

How to make a rod extruder inexpensively from available components

How to make a band saw from bicycle wheels

Particularly interesting

Comments (0)