How to make a cleaning paste for instant tinning of soldering iron tips

Soldering iron tip cleaning paste acts in two directions at once. Firstly, it cleans the tip from oxides and carbon deposits. Secondly, he tins it and wets it with solder. Essentially a comprehensive tool to quickly prepare a soldering iron for work. Factory samples are not very cheap -

Although, making such an analogue yourself for mere pennies is a piece of cake, and now you will see for yourself.

Will need

Well, about 5 minutes of your precious time. Oh yes, you will also need a metal or glass jar for cosmetics or anything else.

How to make soldering iron cleaning paste cheaply

Take a jar and pour citric acid into it.

We take tubular solder.

It is imperative that it has a central core with rosin. We cut it into small pieces into a jar with citric acid.

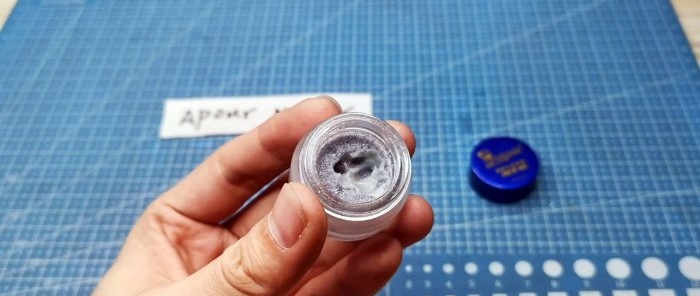

All. All you have to do is mix these ingredients and the paste is ready. It is suitable for both regular copper tips and non-burnable ones.

Testing cleaning paste in action

Preheat the soldering iron to approximately 250 degrees Celsius. As you can see, the solder does not stick to it and does not wet it.

Let's lower the sting into the paste for a few seconds and move it there a little. Do not inhale evaporating vapors; use ventilation after the procedure.

2-3 seconds and the sting is tinned. The solder wetted it.

Next, the soldering iron is ready for use.

Alternatively, you can use aspirin instead of citric acid. But, unfortunately, it gives additional soot.

Advice: If you don’t have solder with rosin inside, then take regular solder and add crushed rosin to the citric acid.

Watch the video

Similar master classes

Particularly interesting

Comments (1)