How to make an electromagnetic vice from a microwave for instant fixation

It is not always convenient to drill metal workpieces on a drilling machine, clamping them in a vice. When using them, it is difficult to position the part at a certain point. It is much more convenient if it is held by a powerful electromagnet. You can do the latter yourself. It will help hold workpieces during grinding, processing with a milling cutter and other tools.

Materials:

- Transformers from a microwave oven – 2 pcs.;

- steel corner;

- pipe 50 mm;

- plexiglass;

- epoxy resin;

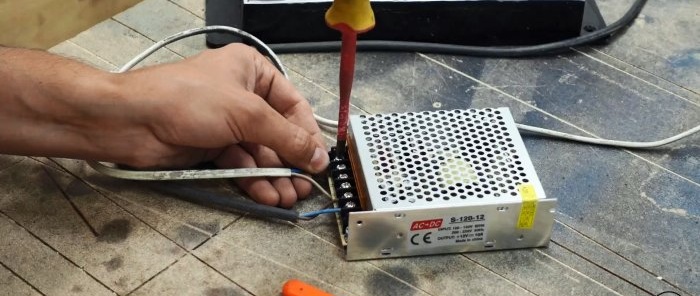

- power supply 12V 10A - http://alii.pub/5yoxos

The process of making an electromagnetic vice from a microwave oven transformer

To make an electromagnet, you need to cut off the plates on the cores of two microwave oven transformers. To do this, 2 cuts are made on the seams, after which the plates are beaten with a hammer.

The transformers are placed on the spread jaws of the vice so that the coils rest against them. In this position, blows on the core can knock it down, thereby removing the coils.Of these, only the primary winding is required (the first with thick wire).

The cores need to be shortened in height so that only the primary winding coil can be placed on them.

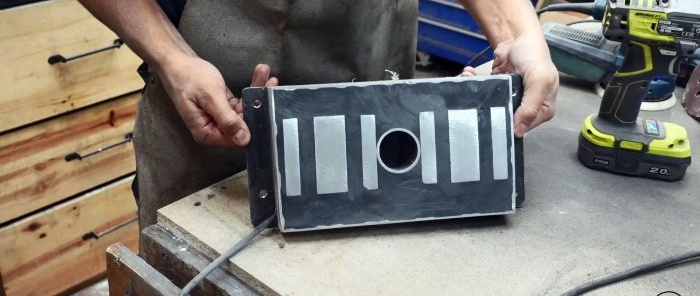

A magnet frame is welded from the corner.

It needs to be temporarily glued with hot glue to the plexiglass sole. The cores are inserted into the frame, and a piece of pipe is installed vertically between them. To prevent it from moving, it can be temporarily glued to them with hot glue.

A little epoxy resin is poured into the frame to glue the cores and tube.

When the composition has set, you need to drill the frame to insert the wire into it. Coils are inserted into the cores, after which a wire is connected to them.

The hole for the wire entry is sealed with hot glue, and the frame is completely filled with resin. It is necessary that its height is sufficient to completely fill the transformers. If the corner is narrow, then you can increase it by welding a strip.

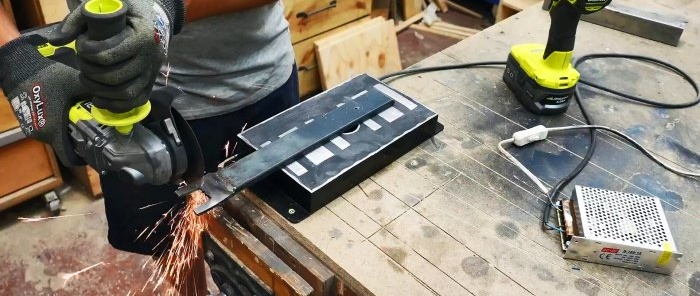

After the resin has set, the surface of the electromagnet is sanded to remove any protrusions.

After this, the frame is painted if desired.

The wire from the electromagnet is connected to the transformer. You need to embed a switch into the power cable connected to it. With its help you can start and turn off the electromagnet.

The device is screwed to a lathe, milling machine, working surface of a table or workbench. To do this, holes are drilled in its corners. Now, when you press the switch, you can launch the magnet, tightly attracting to it all the metal laid on top. The tube in the center will allow you to drill from above without damaging the device itself with the drill.