How to make a template for quickly cutting a profile pipe at angles of 45 and 90 degrees

To quickly cut profile pipes, it is convenient to use a template. It is simply indispensable when using a plasma cutter, as it allows you to guide the plasma torch directly along its edge, without the need for preliminary drawing with a marker.

Materials:

- profile pipe;

- band;

- M8 bolts and nuts – 2 pcs.

Template making process

It is necessary to cut a piece of pipe 20-30 cm long. On one side its end is cut at 90 degrees, on the other at 45 degrees. The short edge of the pipe is completely cut off, the long edge is unraveled in half lengthwise.

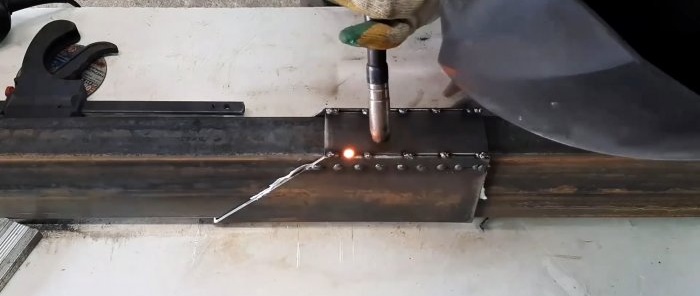

The halves must be sanded from the inside. Particular attention is paid to the weld seam. Then they are put on the same profile pipe. The halves need to be welded together using a strip insert.

In this case, it is necessary to maintain a gap for the template to slide. To do this, place a sheet of paper bent several times under one of the halves.

Narrow inserts are welded on the sides of the template to increase the width. Then you need to weld a short edge to it. Before doing this, be sure to place paper for gaps.

From the side of the short edge, 2 holes are drilled in the pipe, and nuts are welded to them.

Then the wing bolts are screwed into them.

Thus, with their help, the template can be fixed to the pipe so that it does not move during plasma cutting.

Watch the video

Similar master classes

How to bend a profile pipe at a right angle in the carving style

3 ways to weld a profile pipe at right angles without unnecessary

How to weld a beautiful honeycomb partition from a square one

How to make a collapsible connection of profile pipes without welding

3 ways to cut a profile pipe straight

How to make a simple boat from PVC pipes and a trimmer engine

Particularly interesting

Comments (0)