How to use the remains of a dried foam canister? Making a simple device

Once started, a container of polyurethane foam dries out within a couple of months. It is not possible to squeeze polyurethane out of it, even after cleaning the tube. In this case, quite a lot of still liquid foam may remain at the bottom. To remove it, you can make a simple device.

Materials:

- Plexiglas 40-50 mm;

- M8 bolt;

- M8 nuts – 2 pcs.;

- worm clamps 70-90 mm - 2 pcs.;

- old bicycle tube;

- fumlenta.

Fixture manufacturing process

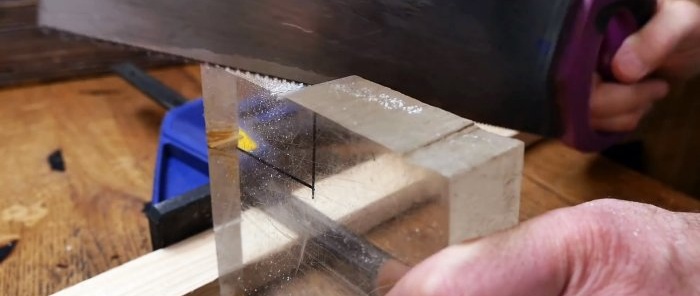

It is necessary to cut a 40x40 mm blank from thick plexiglass.

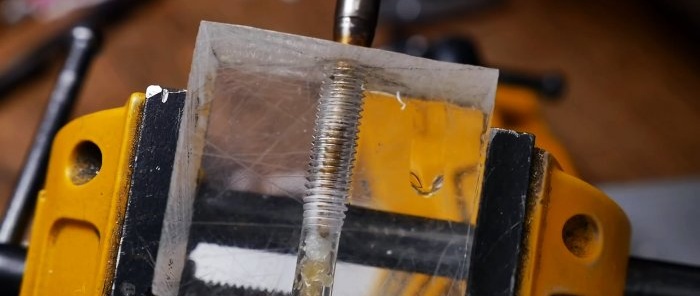

It is drilled through the center and an M8 thread is cut into it.

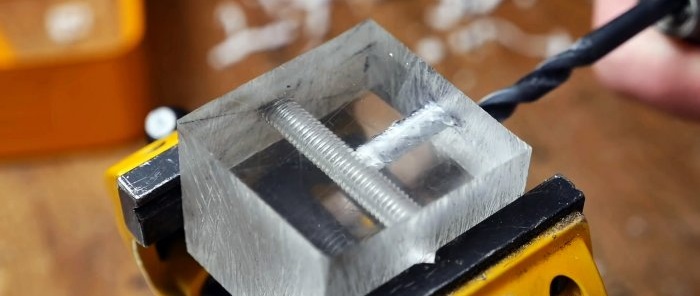

Next, you need to drill a perpendicular hole, connecting it to the previous threaded one.

The part is then clamped in a vice. It is necessary to form a concave rounding of its edge with a 60 mm crown. It is done on any side with a threaded hole.

Now you need to sharpen the long M6 bolt so that it can pierce the foam container.

After this, the plexiglass blank needs to be drilled through 2 more times to insert the clamps. Holes are made parallel to the adjacent thread. In this case, they should pass to the left and right.

A valve from a chamber without a spool is screwed into the adjacent hole onto the fulente or thread.

Having sealed in the same way, you need to tighten the pointed bolt. For convenience, the free edge of the fumlenta can be clamped between two nuts on it.

Clamps are passed through the remaining holes.

Then a rubber gasket is glued onto the concave side. You can use a rubber bandage or cut it from an old bicycle tube. A hole is made in the gasket opposite the tip of the bolt.

To use the device, you need to screw it with clamps at the bottom of the cylinder.

Then a short tube is pulled onto the fitting from the valve.

All that remains is to tighten the bolt to pierce the cylinder and unscrew it back a little.

As a result, the remaining foam will come out through the tube.

After use, the device is washed.

Watch the video

Similar master classes

Particularly interesting