How to make a hole punch for gaskets

To make your own sealing gaskets from cardboard, paronite, rubber and other materials, sometimes you need a punch to make even, neat holes. Such a tool is not difficult to make with your own hands. It will take no more than an hour to make.

Materials:

- reinforcement with a larger cross-section than the hole punch needed;

- a drill equal to the diameter of the hole that needs to be cut;

- machine processing.

Hole punch manufacturing process

It is necessary to cut a piece of reinforcement 10-15 cm long.

At the end it is drilled to a depth of 3-4 cm. You need to use a drill equal to the required diameter of the holes in the gasket.

After drilling, it is necessary to grind the edge of the reinforcement from the outside to create a sharp edge around the circumference. It's important not to overdo it. If the plane of the tip is broken, it must be leveled by grinding down the protruding part to the hollow.

A window needs to be cut out a little higher on the side of the reinforcement within the drilled cavity. It is needed to clean the hole punch.

If the tool is needed for one time, then it can already be used. Simply lubricate the part for which the gasket is needed and apply it to the cardboard or paronite.

Then it is cut out on a soft lining according to the impression left.

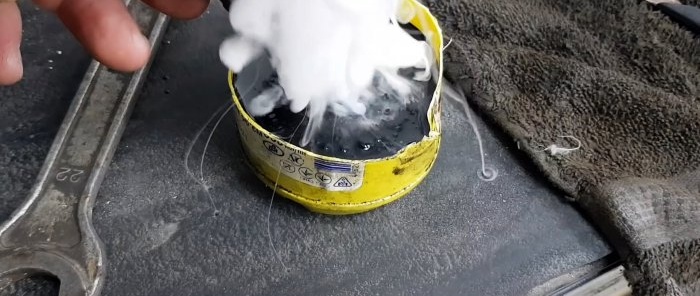

To increase the life of the tool, its working edge can be heated red-hot with a torch and lowered into working.

Thanks to hardening, the hole punch will hold its edge longer and the tip will no longer wrinkle.