How to make a tool for quickly removing an internal seam in a profile pipe

To place one profile pipe into another to obtain a telescopic connection, it is necessary to remove the seam from the outside. Grinding it off on short tubes is not a problem, but on long ones it is impossible without special equipment. Let's look at how to make a tool to remove the internal seam on any pipe.

Materials:

- wooden block or strip;

- spherical burr for metal;

- bearing;

- drill extension.

Tool making process

A good place to start is to make a tool to strip the inside seam of the smallest pipe you usually use. It can be 15x15, 20x20 mm or another. To fit its internal diameter, you need to plan a block 50-60 mm long. Along one side of it, a groove is selected for the seam. It is necessary that the block passes through the pipe with a seam.

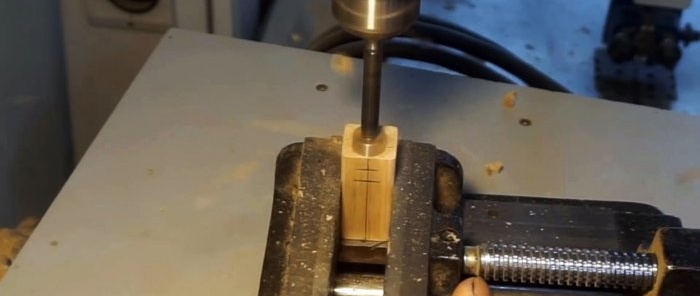

The block is drilled through and through so that a burr can be inserted into it, and with its edge, as it passes through the pipe, it cuts the seam flush with the wall.

At one end the hole should be wide for pressing the bearing.Then it is made narrow by 5-10 mm so that only the burr shank fits into it. To the second edge it expands to match the diameter of the drill extension.

To clamp the extension on the shank, you need to make a cut in the part of the bar where it is located. This is necessary to reach the screws with a screwdriver.

Before using the tool, you need to clamp the pipe in a vice. An extension cord is inserted into it and brought out on the other side, where it is clamped in the drill chuck.

Then you need to start rotating and pull the tool towards you, thereby grinding the seam. To preserve the burr, it should be periodically removed and lubricated.

The same tool is used for large pipes. To do this, you need to make adapters for it from wood. Such U-shaped profiles are twisted with a bar. As a result, the tool size is adjusted to fit pipes of different diameters.

Watch the video

Similar master classes