How to make a brutal door handle

The industrial or industrial style gave birth to techno. All these styles are distinguished by brutality, extensive use of metal, and a sharp transition from one form to another. If you are a follower of this trend, then having the initial skills of a metalworker, you will make a door handle that will please and surprise your family and friends.

Will need

To work, you will need periodic reinforcement and steel plates of different widths and lengths.

You also need to prepare the following tools and equipment:- two sections of profile square pipe;

- bench vice;

- grinder with attachments;

- metal brush;

- measuring instruments;

- hammer and center punch;

- drill;

- welding;

- hand file for metal;

- clamp, etc.

The process of making a handle from twisted reinforcement

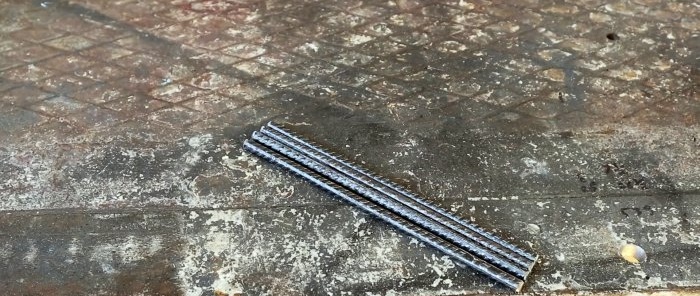

We cut off four equal-length segments from periodic reinforcement of a given diameter and remove sharp edges and burrs at the ends. Bring them to a shine using a wire brush.

We mark a square in the center of two narrow steel plates and at its vertices we mark the centers of future holes, which we drill out with a drill, smoothing the sharp edges with a metal brush.

We clamp one plate vertically in a vice and insert pieces of reinforcement into its holes, on the free ends of which we install the second plate.

We put a piece of square pipe on the end of the free plate and, using it as a lever, begin to rotate the plate clockwise. To facilitate rotation, we put the same piece of pipe on the second end of the plate.

We perform several revolutions, the number of which depends on physical capabilities and the length of the levers. Almost any adult will be able to make maximum revolutions. The result is a uniform interweaving of individual rods around neighboring ones.

If during rotation there is a displacement (bending) of the rods in one direction, then we correct it by striking a hammer through a wooden beam on the plate in the direction opposite to the bend.

Using measuring instruments, we check the vertical and horizontal position of the twisted rods and two plates.

Clamping the plates one by one in a vice, we cut off two ends of the rods flush with the outer side of the plates and weld them to the plates.

We mark the plates according to size and cut off the excess using a grinder. We round the sharp edges with a hand metal file, and the corners of the short side with a grinder.

We install the assembly with the long side of the plates on a wide steel strip and cut off the required length according to the markings; we also round the corners and edges with a grinder and a file.

We mark a wide strip and, opposite the plates, a symmetrically installed unit with twisted rods, drill two holes.

We also drill four holes in the corners of the plate, drilling them out from one side. We drill the internal holes from the opposite side of the plate to a greater depth.

We fasten the strip with the holes in a vice, apply the assembly plates with twisted rods to the internal holes, secure it with a clamp and weld them through the holes to the wide strip.

We clean the welding areas with a grinder and the techno-style door handle is ready for use.

Watch the video

Similar master classes