How to tie reinforcement and make a cool handle

In order not to spend money on buying a handle for an external metal door, we will make it from ordinary fittings. Moreover, it will turn out to be not only original, vandal-resistant, but also very cool. You can make such a homemade product at almost no cost, using the simplest tools, and without having the skills of a locksmith.

From the remains of the old reinforcement we cut out two pieces of equal length. To work on a homemade product, we will need the following tools and devices:

To ensure safe work, we use gloves and safety glasses.

Place two pieces of reinforcement, equal in length, on an anvil, align them at the ends and mark the middle with a piece of chalk.

We light the gas-acetylene welding torch, adjust the flame, and heat the central part of the piece of reinforcement.

Then, without hesitation, we bend the reinforcement using the force of our hands in a canopy, resting the middle against the edge of the anvil or one end against its surface. We use a round pipe to ensure the required bending radius. From time to time we heat the bending zone with a torch flame to facilitate the process.

At the final stage, using a hammer and periodically heating the reinforcement below the bend, actively using the pipe, we form a loop.

In this case, the straight ends of the reinforcing rod should touch along the length and lie in the same plane with the loop, which we bend slightly so that it makes an angle with the ends.

We repeat all the operations performed with the second piece of reinforcement.

We compare the angles of rotation of the hinges and, if necessary, use a hammer to equalize the amount of their bending. We lay the blanks on top of each other so that the ends of one loop fit into the loop of the other.

Now we begin to alternately hit the top of one loop with a hammer, resting the other on the anvil so that they gradually come closer together, remaining at an equal distance from the center. That is, the connection must ultimately be symmetrical.

In order to make the reinforcement “assembly” as compact and dense as possible (and this is strength and beauty), we alternate hammering with heating with a gas burner.

Then we heat the straight sections of the connection closer to the ends and use a hammer to bend them at a right angle in one direction. Using a ruler and chalk, mark a bend equal in length and cut off the excess with a grinder.

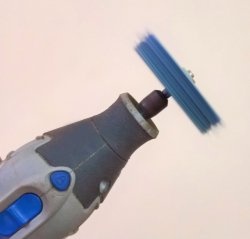

Using a grinder, we grind the resulting product, removing burrs, roughness, and sagging, and weld the original handle from the reinforcement to the outer metal door.

The result is a very cool pen with a masculine character.

Will need

From the remains of the old reinforcement we cut out two pieces of equal length. To work on a homemade product, we will need the following tools and devices:

- massive anvil;

- gas-acetylene welding;

- a piece of round pipe;

- a heavy hammer;

- metal ruler:

- piece of chalk;

- grinder with cutting disc.

To ensure safe work, we use gloves and safety glasses.

The process of making a handle from rebar

Place two pieces of reinforcement, equal in length, on an anvil, align them at the ends and mark the middle with a piece of chalk.

We light the gas-acetylene welding torch, adjust the flame, and heat the central part of the piece of reinforcement.

Then, without hesitation, we bend the reinforcement using the force of our hands in a canopy, resting the middle against the edge of the anvil or one end against its surface. We use a round pipe to ensure the required bending radius. From time to time we heat the bending zone with a torch flame to facilitate the process.

At the final stage, using a hammer and periodically heating the reinforcement below the bend, actively using the pipe, we form a loop.

In this case, the straight ends of the reinforcing rod should touch along the length and lie in the same plane with the loop, which we bend slightly so that it makes an angle with the ends.

We repeat all the operations performed with the second piece of reinforcement.

We compare the angles of rotation of the hinges and, if necessary, use a hammer to equalize the amount of their bending. We lay the blanks on top of each other so that the ends of one loop fit into the loop of the other.

Now we begin to alternately hit the top of one loop with a hammer, resting the other on the anvil so that they gradually come closer together, remaining at an equal distance from the center. That is, the connection must ultimately be symmetrical.

In order to make the reinforcement “assembly” as compact and dense as possible (and this is strength and beauty), we alternate hammering with heating with a gas burner.

Then we heat the straight sections of the connection closer to the ends and use a hammer to bend them at a right angle in one direction. Using a ruler and chalk, mark a bend equal in length and cut off the excess with a grinder.

Using a grinder, we grind the resulting product, removing burrs, roughness, and sagging, and weld the original handle from the reinforcement to the outer metal door.

The result is a very cool pen with a masculine character.

Watch the video

Similar master classes

Particularly interesting

Comments (2)