How to make a simple valve clamp

You can quickly, reliably and accurately tighten wire clamps using a special device - a clamp. It is very simple, so it can be made from scrap materials. Let's look at how to make it from an old valve and stud.

Material:

- Valve from internal combustion engine;

- nut M10;

- M10 pin;

- strip 20 mm.

The manufacturing process of the clamp

A nut is welded to the valve stem, but so as not to flood the threads with welding.

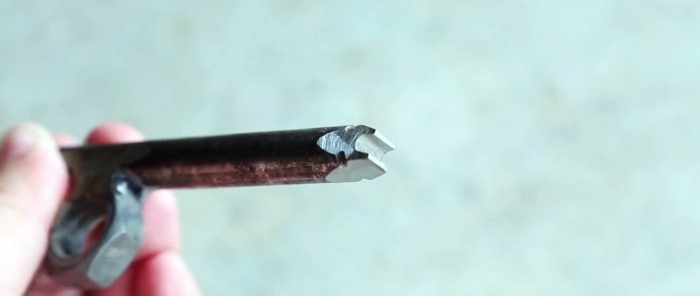

Then its edge needs to be sharpened by making a longitudinal cut with two notches.

Next, take a piece of threaded rod 10-15 cm long. It needs to be drilled with a 3-4 mm drill in two places closer to the center with a gap of 30 mm. Then a piece of strip is welded perpendicularly to the end of the stud to form a handle.

The stud screws into the nut on the valve. The latter should be located on the thread between the holes.

To use the device, you need to bend a piece of wire in half. The loop obtained from it is tightened on the hose.

Then the ends of the wire are inserted into the holes in the pin, and the edge of the valve rests against the loop.

By rotating the pin by the handle, you can tighten the wire clamp. After this, we bend the wire by tilting the clamp forward.

Now the clamp is already held in place by bending. Cut off the excess wire and remove the device.