How to make a hot air gun for soldering from a regular soldering iron

Soldering SMD components with a conventional soldering iron is a very complex process. If you have a similar job to do, but you don’t have a commercial heat gun, then make it yourself. To do this, you just need to make a small upgrade to your soldering iron.

Materials:

- Electric soldering iron 200 W - http://alii.pub/5y8b6s

- fan 12V snail - http://alii.pub/5y8bah

- nozzle for hot air gun;

- thin tube;

- power supply 12V - http://alii.pub/5y8bdl

- connector for power supply;

- wires;

- heat-resistant insulation - http://alii.pub/5y8bgb

The process of converting a soldering iron into a hot air gun

It is better to make a hot air gun from a powerful soldering iron, since a weak one will not be able to heat the air flow strongly enough.

The soldering iron is disassembled. You need to remove its tip to get to the heating element, and the handle.

The spiral with the tube is removed from the soldering iron. The latter is muffled on one side, this needs to be fixed. It is necessary to release the ends of the spiral and remove the plug.

Next, you need to make a curved air duct from a tube in order to insert it into the body of the soldering iron to connect the fan. To do this, a wedge is cut into it, which will allow it to be bent.

You will need to cut a window in the body of the soldering iron to insert the tube.

The ends of the spiral are insulated. Then it is installed back into the housing, and it is assembled.

The edge of the tube is insulated and it is placed in the housing.

A clamp is used to secure it.

A fan is installed on the edge of the tube. Using an elastic band, we connect the blowers.

Then the hot air gun attachment is put on the soldering iron itself.

A piece of tube is placed inside the thermoelement.

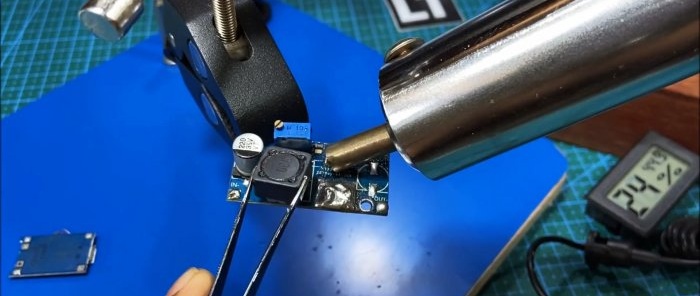

All that remains is to solder the wire to the fan and tape it to the power cord of the soldering iron.

A connector for the power supply is soldered to the end of the wire. Thus, by connecting the power supply to the fan and plugging the soldering iron into the outlet, we get a stream of hot air at the output that easily melts the solder.