The simplest guide for cutting logs into boards with a chainsaw with your own hands

Amateur carpenters often experience an acute shortage of good lumber from deciduous trees. The products on sale are mainly coniferous boards and bars. If you require a more noble wood, you can make a simple guide beam and use it to saw hardwood logs into the required lumber.

What you will need:

- Planed board 50x200 mm, 25x200 mm;

- plywood 20 mm;

- M8 bolts – 2 pcs.;

- M8 nuts – 2 pcs.;

- extended M8 nut.

The process of manufacturing a device for cutting logs into boards with a chainsaw

The proposed design is a guide beam that is screwed onto a log. A conductor carriage with an attached chainsaw slides along it. Together, they set a straight path when guiding the chain saw bar, which results in an almost perfect cut.

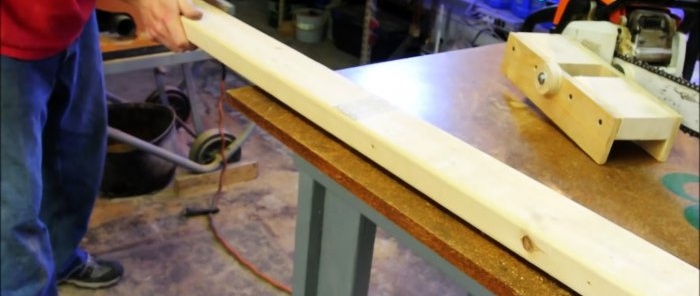

The beam itself can be made from any flat planed board with a thickness of at least 50 mm and a width of 150-200 mm. The length of the beam can be any, depending on which logs need to be unraveled.

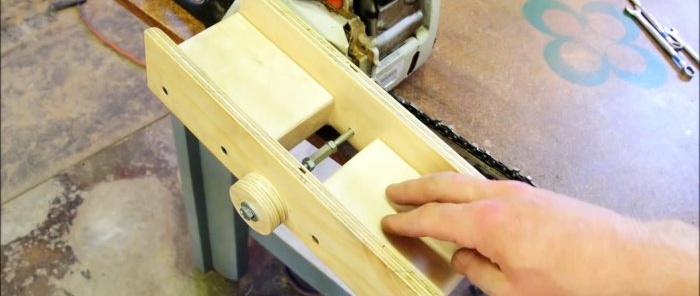

The conductor itself is made of plywood and an inch board, fastened together with self-tapping screws. It has a U-shape. Its sides are cut out of plywood. Their size is 30x7.5 cm. The top is made of two boards 12 cm long. Their width should correspond to the guide beam. When assembling the jig, a gap is maintained between the top boards.

The sidewalls of the conductor are drilled in the center. The holes should be positioned so that they do not protrude below the top boards. Long bolts are inserted into the holes on both sides, which must be connected with an extended nut. To prevent them from unwinding, you will need to lock them. Before installing it into the jig, you will need to place plywood washers made using a core drill on the bolts.

The jig must be screwed to the chain saw bar using the tie obtained from the bolts. To do this, the latter is drilled.

It is necessary that the saw can rotate on the axis connecting it to the carriage. To do this, cut-out plastic gaskets are placed between the conductor and the plywood washers, and everything is lubricated with graphite powder.

In this form, the carriage is completely ready for use. But before this, it is advisable to grind the guide beam so that sliding along it is with minimal resistance.

To use the device, you need to screw the guide beam with self-tapping screws onto a log laid horizontally on a small elevation. If it has a widening at the beginning, then it should be cut down. The beam should lie stable without deflection.

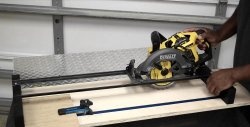

After this, the saw is installed with a carriage on the beam, and moving along it, it cuts off the first slab. It is important to check that the tire does not touch the ground. Then the carriage turns over and the log is cut on the other side.The result is a workpiece with two parallel planes.

Next, the workpiece is laid on its side, the guide beam is attached to the top, and it unfolds into boards of the required width. It can be cut even easier and faster on a circular table with a parallel stop, since the planes on it are already formed.