How to make plastic (filament) from a PET bottle for a 3D printer

Those who are interested in 3D printing are sometimes simply shocked by their costs for plastic printing thread (filament). Although she is not very expensive, she is consumed in large volumes, so the sums for her ass are considerable. To save money, filament can be made for free from ordinary plastic PET bottles.

Equipment needed:

- Bottle cutter;

- tire inflation pump;

- heater 200-225 degrees Celsius with 1.75 mm output nozzle;

- drawing and winding mechanism.

Process of making filament from PET bottles

PET bottles are used as raw materials for the production of filament. Ideally, they should be colored. They need to be leveled before use. For this purpose, a regular bottle cap is modified. You need to install a valve from a car camera into it. With its help, the bottle is pumped with air using a regular pump to increase the pressure inside (more details here - https://home.washerhouse.com/en/6732-kak-vyprjamljat-ljubye-figurnye-pjet-butylki.html).

Next, the valve is clamped in the screwdriver chuck. You need to rotate the inflated bottle over a lit gas burner. It will warm up, soften and, thanks to internal pressure, equalize.

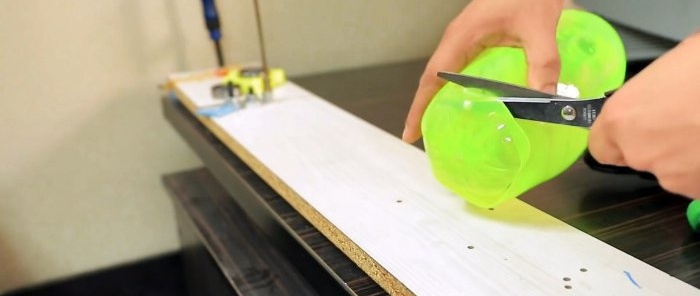

A straight bottle is cut into a strip using a bottle cutter. It will turn out more uniform than if it were dissolved without preparation. If the walls of the bottle are thick, then the width of the tape should be 5-6 mm. From a thin bottle of mineral water, it is better to cut 7-8 mm wide.

The edge of the tape is cut at an angle, after which it is launched into the nozzle of a heated heater. To work with PET tape, its temperature must be +200-225 degrees Celsius. The diameter of the nozzle outlet is made 1.75 mm, while the inlet is countersunk to make it easier for the wide tape to fit in and change shape.

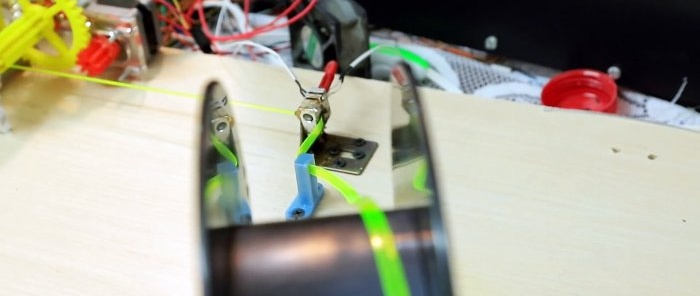

The edge of the filament pulled through the hot nozzle must be tied and connected to the drawing and winding mechanism. It is a stepper motor with gearboxes and a coil. Parts for it can be printed on a printer. The winding speed is adjustable so that the tape has time to heat up enough and change shape.

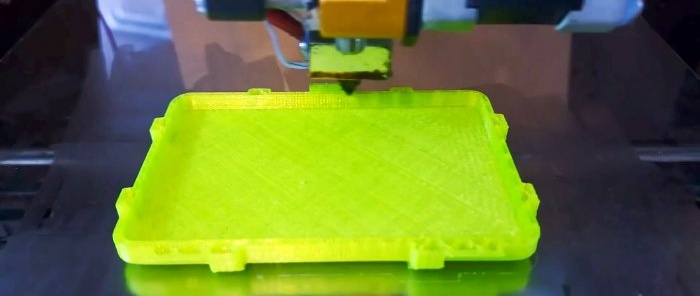

To make the rod long, the tapes can be glued together before production, heating the ends to +270-280 degrees Celsius. The resulting filament prints perfectly when the temperature is set to +250-260 degrees Celsius.

All equipment necessary for production can be made in a handicraft way. There are no special requirements for it except the possibility of adjustment. For the heater this is the corresponding temperature, and for the winding mechanism the rotation speed of the coil. As a result, you can literally get high-quality filament from garbage.

If the ribbon is straight, and it will be if you first straighten the bottle, then the quality of printing with such a rod is ideal.