How and with what to quickly dismantle old coatings during repairs

No less difficult stage of repair than finishing is the dismantling of old plaster, tiles, and screed. This can take a lot of time. But if you find the right tool for each type of coating, you will be able to finish the rough work much faster.

Removing thin layers of putty from concrete slabs

Thin layers of putty can be removed from smooth, hard substrates using a universal scraper into which blades for a mounting knife are inserted. They can very quickly and quietly knock down layers of 1-5 mm.

You need to wear glasses when using this scraper. Be sure to use high-quality hardened blades. The cheap ones have corners that break off and fly off in different directions like bullets, so it’s better not to save money so as not to get injured.

Please note that a sharp blade removes the thinnest layers, while a dull blade can remove quite thick layers of 3-5 mm. In addition, the blunt can work on rough surfaces. They are also easy to remove linoleum residues.

For the tool to work, you need to constantly turn it over to the other side after a couple of wires.Otherwise, the edge will rub off within a minute.

Removing screed, self-leveling floor, tiles, plaster

Thick layers of old coatings can be knocked down with a hammer drill. However, its impacts spread across the floor slabs, so that neighbors in several entrances will learn about the dismantling. It is better to work with a hammer drill where there are no other options for knocking down the old coating.

Aligning corners and protrusions

Similar work as a hammer drill can be done with a grinder with a diamond grinding bowl. This is much quieter, but comes with a huge dust emission. Therefore, a construction vacuum cleaner must be connected to it.

Any discs for angle grinders on AliExpress with a discount - http://alii.pub/61bjly

The bowl allows you to grind off all the irregularities. It is especially convenient to use if you need to straighten curved corners by smoothing out the protrusions. This will further reduce the consumption of plaster.

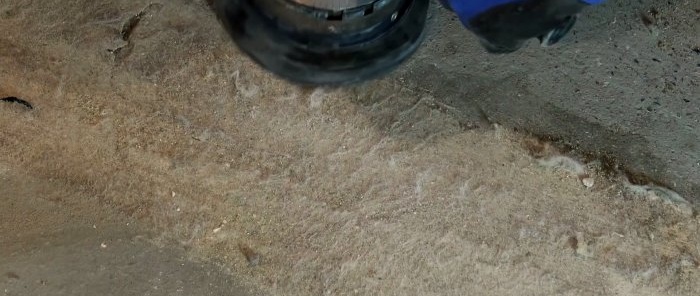

Rough quick dismantling

The dismantling is done very efficiently by a stripping machine.

It works similar to a grinder with a diamond blade, but has an impact effect. Due to this, it literally peels off and at the same time knocks off the base of the coating. Even if it is uneven, it will allow you to knock out poorly holding plaster or screed from the recesses.

The stripping machine is also capable of removing waterproofing. It turns everything into dust and fine crumbs. That is, you can use a less powerful vacuum cleaner for it than when working with a diamond tool.

Any discs for angle grinders on AliExpress with a discount - http://alii.pub/61bjly

Watch the video

How to make a speed controller for a power tool without knowledge of electronics - https://home.washerhouse.com/en/8044-kak-sdelat-reguljator-oborotov-jelektroinstrumenta-bez-znanija-jelektroniki.html

Similar master classes

Particularly interesting