How to bypass a round pipe with a rectangular profile

In the household, sometimes it is necessary to connect a profile pipe to a round one. Almost any adult can do this kind of work if he has ordinary tools and some skill in handling them.

Will need

Materials:- a small piece of cardboard;

- a piece of round pipe;

- three sections of profile pipe;

- rivets.

Welding electrodes for general purposes on AliExpress at a discount - http://alii.pub/606j2h

Tools and accessories: marker, scissors, metal ruler and square, grinder, vice, pliers, flat file, hammer, drill, riveter.The process of connecting a profile pipe with a round one

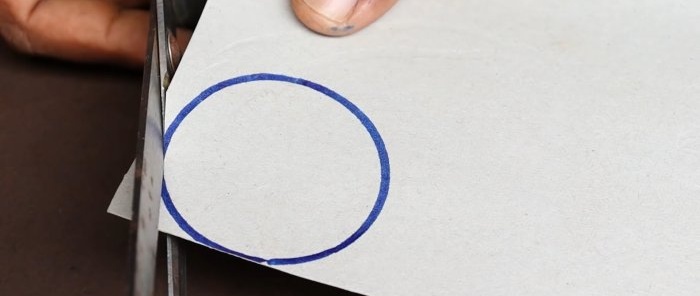

We place the round pipe with its end on the cardboard and trace its outer contour with a marker.

Using scissors, cut a circle along the markings in the cardboard.

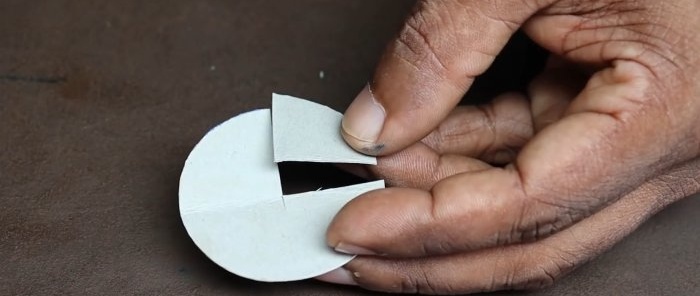

Fold the cut out cardboard circle in half. We make a cut along the fold line to the center of the circle. We bend the sector (1/4 of the circle) along the cut and cut it off from the circle.

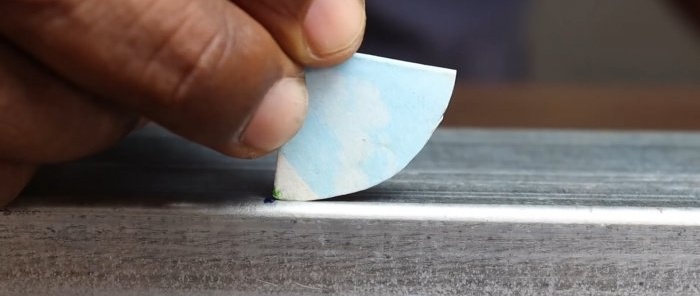

We make a mark on the edge of the profile pipe, and on it we set the beginning of the arc of the cardboard sector and roll it along the edge of the pipe. We also make a mark where the arc ends.

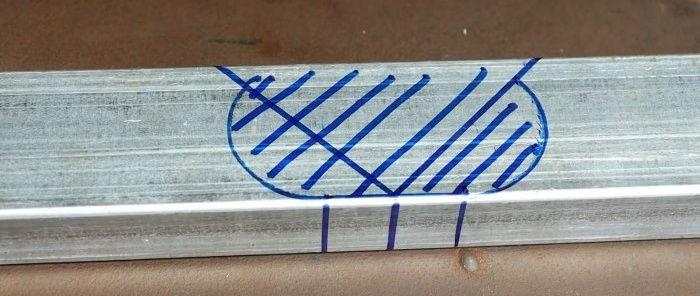

We measure the distance between the points and find the middle between them, which we also mark. From it we draw two lines at 45 degrees along the side of the profile pipe.

Fold 3/4 of the cardboard circle so that the cutting lines match in length. Cut the resulting figure along the fold line.

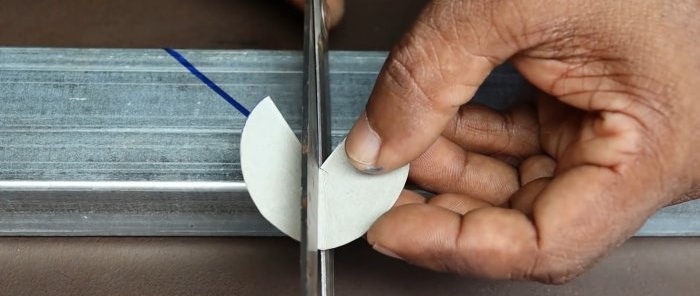

We align the beginning of the 3/4 circle arc with a point on the edge of the profile pipe, indicating the end of the 1/4 circle sweep, and the opposite radius with a line drawn at 45 degrees. Without changing the position of the 3/4 circle sector, we outline its arc with a marker.

We do the same from the beginning of the sweep of 1/4 of the circle and connect the points of the beginning and end of the sweep with a line.

We continue to exit the lines drawn at 45 degrees along the narrow side of the profile pipe. From the points where they exit on the wide side, we draw two lines at 45 degrees, from the intersection point of which, on the narrow side, we draw a vertical line. Parallel to it on the left and right we draw lines at a distance of half the arc of the circle of the 1/4 circle sector.

We repeat all the constructions made earlier on the other wide side of the profile pipe. Shade the surface of the pipe to be cut.

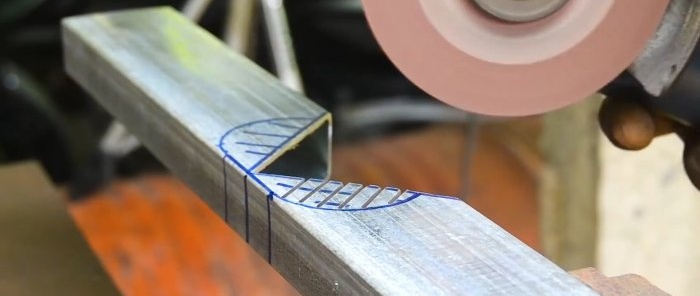

We carry out the cutting with a grinder, removing individual fragments with pliers and cleaning the edges around the perimeter of the cutout.

We wrap the cutout in the profile pipe around the round one and bring the ends of the first one together so that the cutout tightly clasps the round pipe and the sides form a right angle.

Watch the video

How to connect tubes at any angle without welding - https://home.washerhouse.com/en/6283-kak-bez-svarki-soedinjat-trubki-pod-ljubym-uglom.html

Similar master classes