How to make stiffeners on a sheet of metal without a press

Sometimes it may be necessary to bend a relief part from sheet metal, perhaps even with a concave or convex pattern. This could be a box lid, decorative trim, etc. In production they are obtained by pressing between dies. But there is a technology that allows you to make such complex parts at home without a press.

Materials:

- Soft sheet metal;

- MDF 18 mm;

- M6 bolts and nuts;

- steel round timber for making a breakdown.

The process of making embossed panels

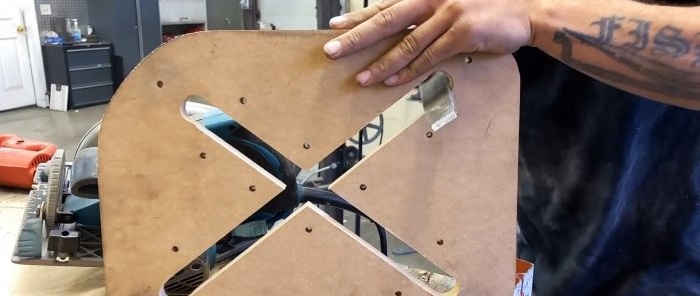

The first step is to make a template of the future part from paper. Half of the form is cut out from MDF using a template. Its counter part should be smaller so as not to interfere with the work of the hammer.

The edges of the halves will need to be milled on one side.

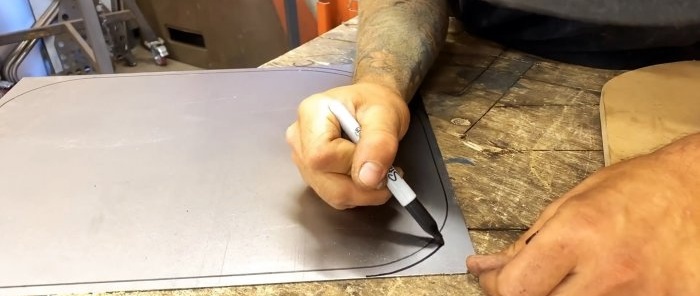

A panel blank is cut from sheet metal. It is made a little larger.

Part of the workpiece will go into bends along the edge, so the higher the sides should be, the greater the tolerances.

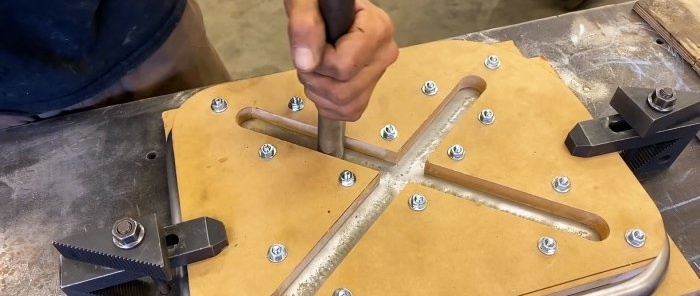

It is then placed between the matrices. All 3 layers are drilled together and bolted together.

Now the clamped metal can begin to bend.Using sliding light blows, it is necessary to bend the sides around the circumference onto the wide half of the matrix. You need to move in a circle, bending the sides little by little.

After this, the matrix is disassembled.

Through grooves are cut out on its halves along the outline of the desired panel relief. In this case, it will be 2 intersecting lines.

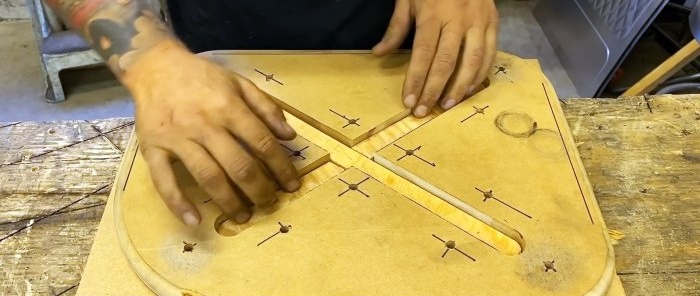

The depth-limiting slats need to be cut into the groove of the bottom panel. They will not allow the metal to bend more than expected and tear. In addition, with them the recess will be uniform in depth.

The panel blank is again pulled together into halves of the mold. Inserts are placed under the bottom.

For further work, you need to grind a hole with a rounded end from the round timber. It will form a recess.

Then, by hitting it with a hammer, we bend the relief along the matrix.

If you have an electric or pneumatic hammer drill, you can make a knob from a rod and weld it onto the bit. Then it will be much faster and easier to tap the relief.

The panel made in this way is then slightly sanded to remove traces of dents. They can also be puttied and then painted over. If the panel must be solid without perforation, then the holes are welded.

Watch the video

Similar master classes