How to Make a Self-Locking Door Latch from Leftover Sheet Metal

Instead of purchased latches for the doors of auxiliary rooms, which cost a lot of money, you can get by with a homemade one, made from leftover sheet metal that is no longer good for anything. It can be done by any adult who knows how to handle ordinary metal tools.

Will need

Materials:- Remains of sheet steel;

- fragment of steel angle;

- a piece of steel strip;

- steel rod;

- mounting screws;

- the padlock.

Manufacturing process of self-locking door latch

The thicker the metal used, the stronger the latch, but precautions are necessary, otherwise the product will turn out to be bulky and its parts difficult to process.

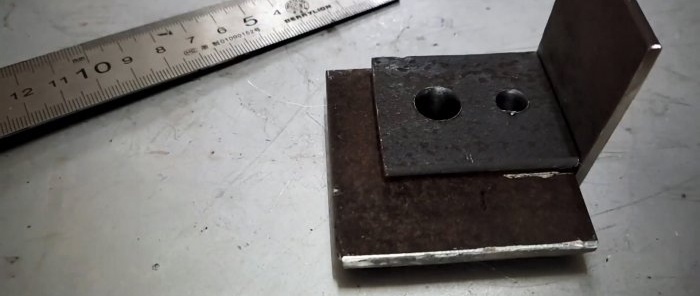

We cut out a square of the given dimensions, a fragment of a corner, a section of strip equal to the internal size of the corner flange from sheet metal.

We place a square on the inner shelf of the corner, and a fragment of the strip on it. We align the sides of the parts along the edge of the corner flange, fix them with pliers-clamps and secure them in two places by welding.

We mark the “pie” and drill two holes in it, the outer one being larger in diameter.

In the part of the square protruding from the side, at the level of the large hole, we drill the same one.

Remove the potholders and separate the pieces of the “pie”. We tighten the corner and strip using a bolt and nut along the smaller hole. For the larger hole we make a slot equal to its diameter from the edge of the corner shelf and strip.

Separate the corner and strip. We insert a bolt into the smaller hole of the corner from below, put a square on it, also using the smaller hole, and a plate on top.

Between the plate and the square we insert the remainder of the cutting disc from the grinder. Pressing the plate against the cutting disc, we weld the plate to the corner flange. We remove the disk and get a gap between the plate and the square.

Using a plate, we mark out the square and remove the shaded areas, smoothing the perimeter of the cutout and cuts with a grinder and hand files.

We symmetrically weld a small square from a flat sheet to the figure obtained from the square, below the “tongue” of the future latch, making chamfers for the welding seams.

We insert the tongue between the angle shelf and the plate so that the small square slides along the sides of the angle shelf and the plate.

We insert a steel rod into the small through hole from the flange side of the angle and flush with the surface of the plate. We cut off the rod protruding from the corner and weld the remainder to the flange of the corner from the outside and grind the welding area.

We screw the resulting structure with the outer side of the shelf to the door jamb so that the plate and the second shelf of the corner are in a vertical position, and the small square of the tongue lies on top of them.

Then the L-shaped round handle, welded to the door leaf, with its curved part presses the tongue along the bevel when closing the door, lifts it, and with further movement falls into the hole of the tongue, which at the same time lowers and stops the handle rod.

To open the door, you need to lift the tongue by the upper square and release the handle rod. To prevent unauthorized opening of the door, a lock is hung at the bottom of the oblong hole and then it is impossible to lift the tongue and release the handle rod.

Watch the video

Similar master classes