How to Make a Bearing Jig for Easy and Fast Chain Making

Chains are used to tie animals, lift water from a well, hang structures, loads, etc. They are used to make children's swings, decorative fencing, jewelry, etc. Chains are an expensive product, so it makes sense to make them yourself. But first we’ll make a device for bending chain links. This does not require any special skill, just the ability to handle a grinder and welding equipment is enough.

Will need

Materials:- friction bearing;

- finger with a head with two flats;

- steel strip;

- bolt and nut;

- wire or rod.

Welding electrodes for general purposes on AliExpress at a discount - http://alii.pub/606j2h

The process of manufacturing a device for forming chain links and assembling it

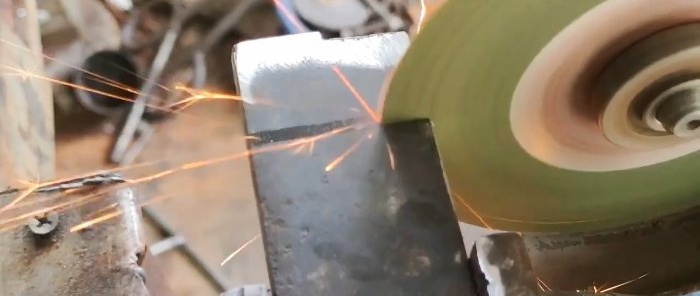

We place the head of the finger on a horizontal surface and, using a square pipe of the required size, mark a line for its shortening on the side of the finger, which we do with the help of a grinder.

We mark a point on the cylindrical surface closer to the end of the shortened finger and drill a transverse hole of a given diameter along it on a drilling machine.

We mark and make a slot from the end of the shortened finger to the transverse hole in it. Transversely to the slot at one end, we shorten the resulting segments perpendicular to the slot to the depth of the slot.

From one shortened segment of the finger we cut off a second small segment to the depth of the slot so that its chord is parallel to the slot.

We grind the surfaces obtained after cutting with a grinder, and round the edges using a hand file.

We put the bearing with the inner ring on the shortened pin, lift it above the head and weld the inner ring to the pin on both sides.

We weld a rigid steel strip to the outer ring, radially flush with its upper edge.

We rest the other strip vertically with its narrow side against the protrusion of the pin above the inner ring of the bearing, mark and cut out a recess equal to the height of the protrusion and the length to the outer part of the outer ring.

We also mark a horizontal line at the height of approximately the end of the shortened pin, cut off its lower part from the rest of the strip and weld it radially to the outer ring of the bearing and the previously welded strip.

We weld the nut with the bolt screwed into it to the outer end of the radially welded plate so that the bolt is horizontal. With its help we will set the length of the chain links.

To form chain links, place a piece of wire or rod of the required length in the slot of the finger, press it against the end of the bolt and turn the lever. Since the inner ring of the bearing and the pin with the slot are stationary (the head of the pin is clamped by the flats in a vice), and the outer ring of the bearing rotates along with the plate, its end, bending around the wire, bends it around the outer side of the pin.

We bend the second side of the wire blank in the same way. The result is a chain link.

To make a chain, bend both ends of the first link, then only one end of the second and subsequent links, thread it into the first link or the previous one, and bend the second end of the link. This way you can make a chain from any number of links.

Watch the video

Similar master classes